Profiling anti-blocking leaf vegetable harvester and control system and method control thereof

A control system and harvester technology, applied in the field of agricultural machinery, can solve the problems of complex ridge surface environment, no lateral profiling, anti-blocking, large ridge surface information error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

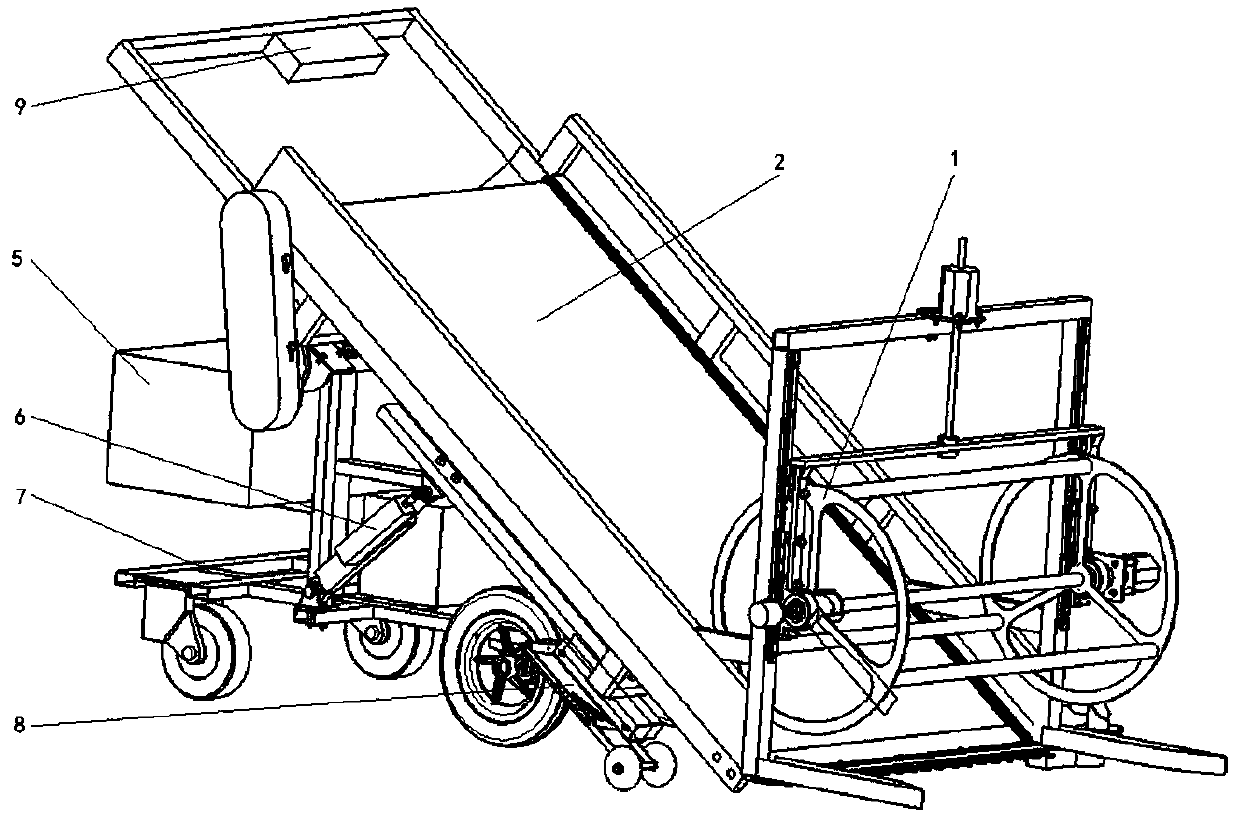

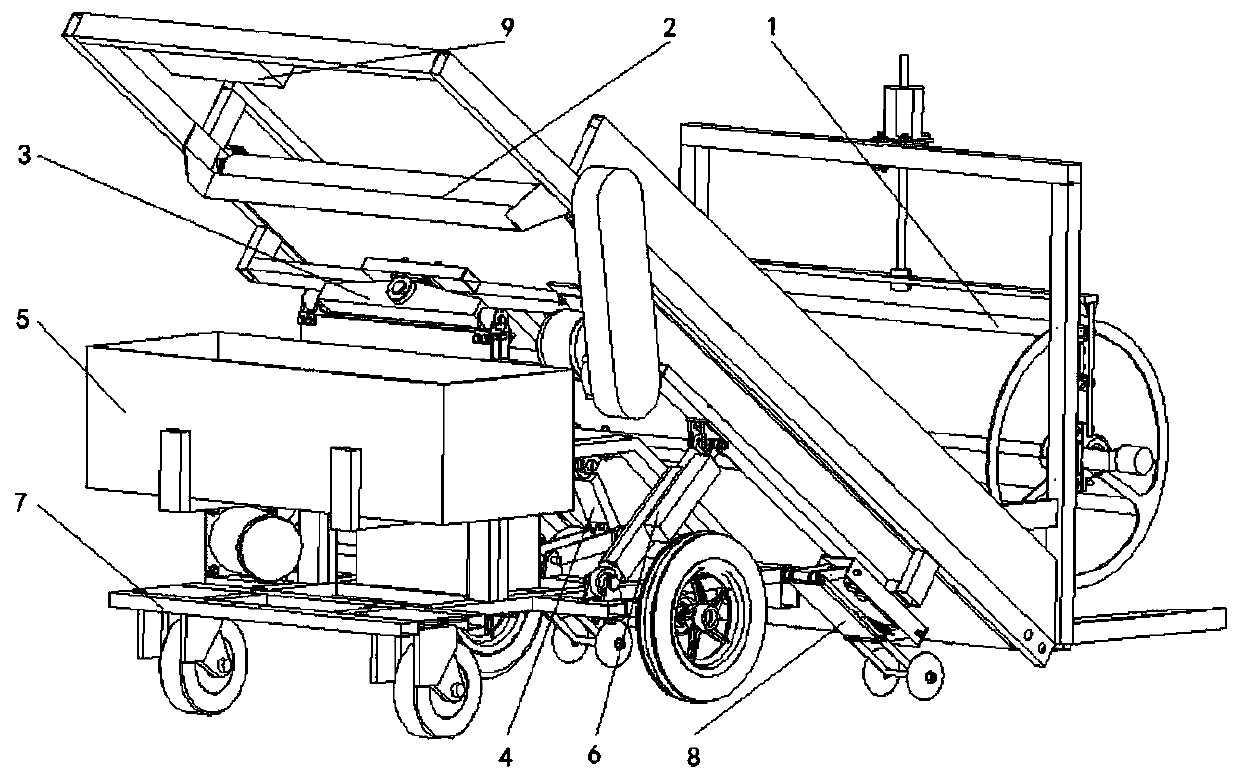

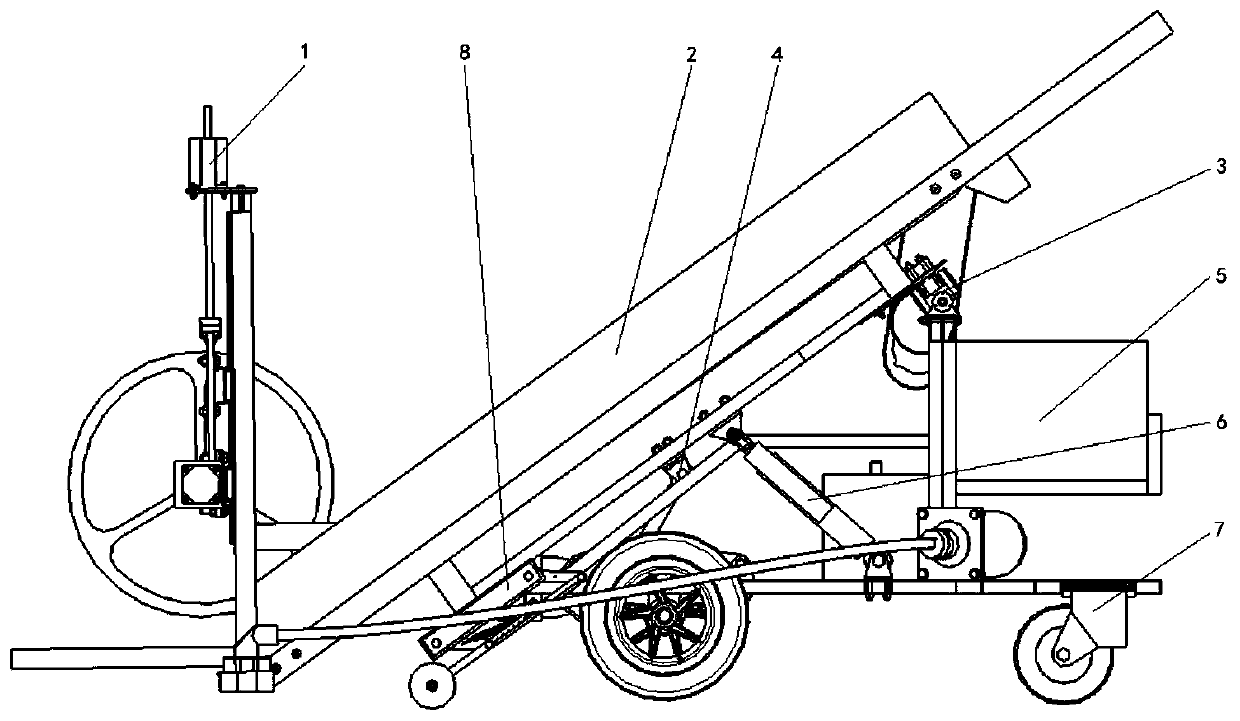

[0099] figure 1 , figure 2 , image 3 It is a preferred embodiment of the profiling anti-blocking leafy vegetable harvester, and the profiling anti-blocking leafy vegetable harvester includes a reel assembly 1, a header assembly 2, and a header chassis connection assembly 3. Header chassis limit assembly 4. Collection device 5. Header adjustment assembly 6. Chassis assembly 7. Ridge surface detection assembly 8 and control system 9. The reel assembly 1 is laterally symmetrically installed on the front part of the header assembly 2, and the header assembly 2 is connected to the chassis assembly 7 through the header chassis connection assembly 3; The header chassis limit assembly 4 is installed between the header assembly 2 and the chassis assembly 7; two sets of header adjustment assemblies 6 are installed laterally and symmetrically between the header assembly 2 and the chassis assembly. 7 are used to adjust the posture of the header assembly 2 in the horizontal and vertic...

Embodiment 2

[0122] A control system for a profiling anti-blocking leaf vegetable harvester according to Embodiment 1 has the beneficial effects of Embodiment 1, and will not be repeated here.

[0123]The control system of the profiling anti-blocking leaf vegetable harvester includes a detection mechanism, a control system 9 and an execution mechanism. The detection mechanism includes a reel encoder 1-7, a travel encoder 7-3-1, a torque sensor 1-16, an ultrasonic sensor 8-15 and a displacement sensor 6-4. The executive mechanism includes a reel lifting motor 1-10, a reel rotating speed motor 1-18 and an electric push rod 6-3. The detection mechanism is connected with the control system 9, and the control system 9 is connected with the execution mechanism; the control system 9 includes a header profiling control module, a reel speed control module and a reel anti-blocking control module.

[0124] The header profiling control module obtains the length l of the current left electric push rod...

Embodiment 3

[0149] A control method for the control system of the profiling anti-blocking leaf vegetable harvester described in Embodiment 2 has the beneficial effects of Embodiment 2, and will not be repeated here.

[0150] The control method of the control system of the profiling anti-blocking leaf vegetable harvester comprises the following steps:

[0151] Header profiling control: the header profiling control module of the control system 9 obtains the length l of the current left electric push rod 6-3 through the displacement sensors 6-4 on the left and right sides 0l , and the length l of the current right electric push rod 6-3 0r , and the included angle α between the left and right sides of the header assembly 2 relative to the ridge surface is respectively obtained through the mathematical model of the header inclination angle l 、α r ; The vertical distance d between the top inner side of the parallel four-bar mechanism on the left and right sides and the detection plate 8-8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com