Sugarcane planting and managing method for eliminating wide-narrow row craters

A management method and technology of wide and narrow rows, applied in the field of sugarcane planting, can solve problems such as sugarcane lodging, affecting sugarcane machine yield, unfavorable sugarcane growth, etc., to improve plant height uniformity, improve lodging resistance, and improve planting soil cultivation devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 A kind of soil-building type high-efficiency precision sugarcane planter

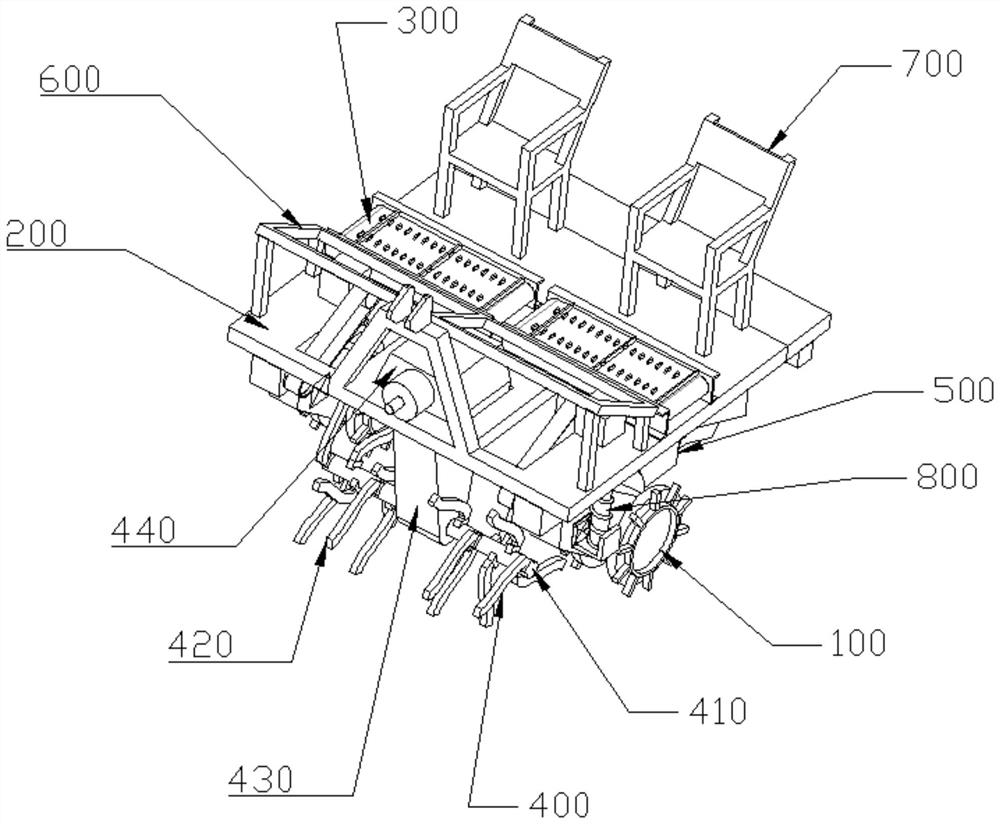

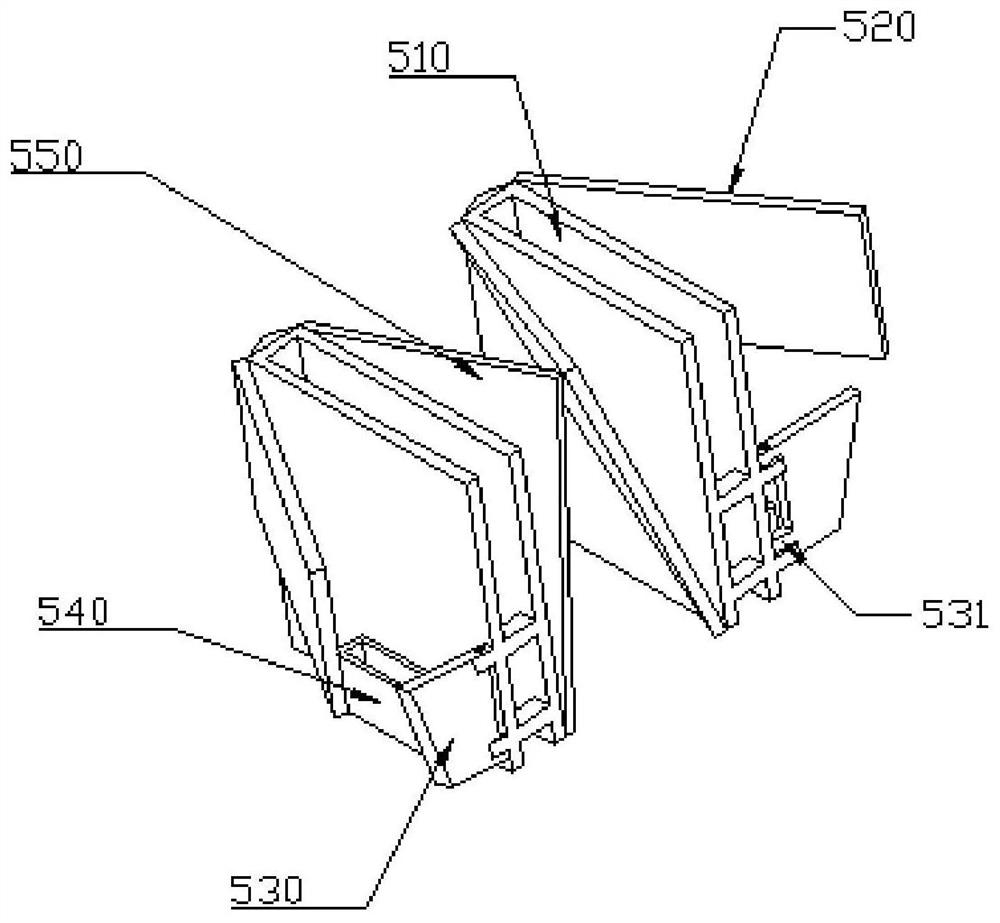

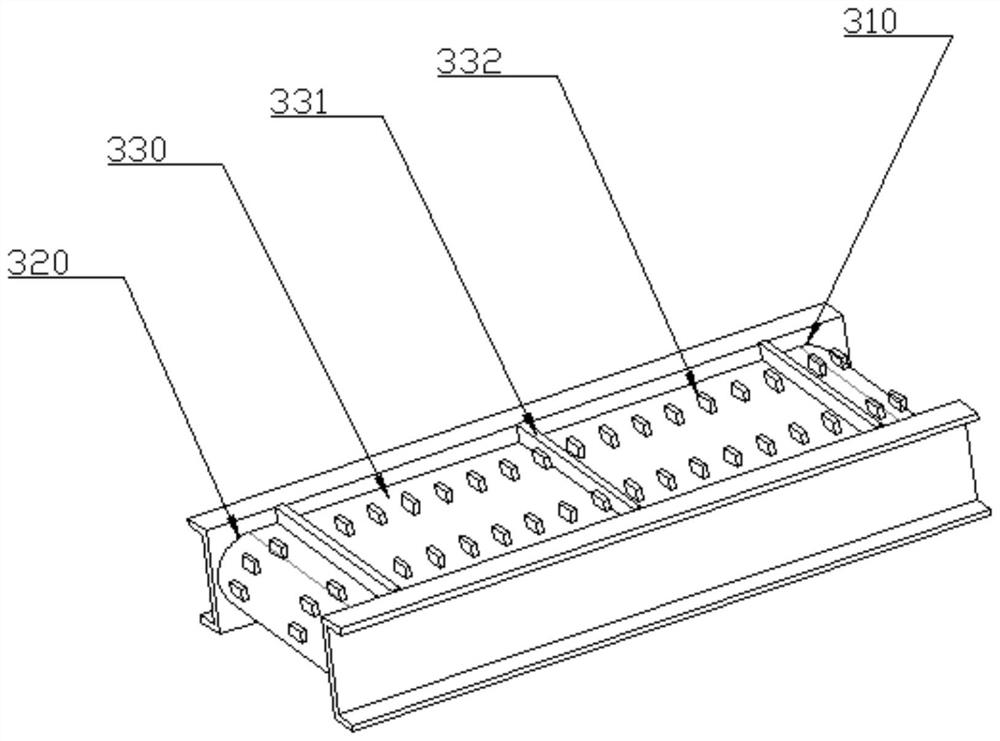

[0052] Such as Figure 1-3 As shown, a soil-building type high-efficiency and precision sugarcane planter includes: a frame 200 with traveling wheels 100, two seeding devices 300 are arranged above the frame 200, and a front portion below the frame 200 is provided with Rotary tillage device 400, described rotary tiller device 400 rear is provided with planting earth-building device 500 and soil-building device, described planting and earth-building device 500 comprises planting tank 510, soil dividing plate 520 and soil-building plate 530, and described soil-building device comprises soil-building plate 550 . There are two planting grooves 510 , which correspond to the planting positions of the two seeding devices 300 . This planter can also be equipped with fertilization device, spraying device and film covering device according to needs, and can complete the processes of row ditc...

Embodiment 2

[0060] A sugarcane planting and management method for eliminating wide and narrow row craters, comprising the following steps:

[0061] (1) Soil preparation: Use the subsoiling spreader to carry out subsoiling operations with a depth of more than 50cm. At the same time, use the spreader to open a planting ditch with a depth of 30-35cm and a width of 40-50cm. The distance between the centers of two adjacent rows of planting ditch is 1.95- 2.40m.

[0062] (2) Sugarcane seed preparation: Use a seed cutter to cut the cane stalks of healthy seed stems into standard double-bud section sugarcane seeds, the length of which is 20-25 cm; the cut sugarcane seeds are soaked in the coating agent and then used for planting . Preferably, the healthy seed stems are stripped and then dried for 1-2 days before being cut.

[0063] The coating agent is composed of the following ingredients in parts by weight: 5-7 parts of plant growth regulator, 0.5-0.7 parts of 40% difenoconazole, 1-1.2 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com