A small creeping peanut digging harvester for mulching planting

A harvester and peanut technology, which is applied to excavator harvesters, harvesters, applications, etc., can solve the problems of hindered popularization and use of peanut excavator harvesters, loss of peanut fruit falling, and failure to overturn, etc. The quality and reliability of equipment operation, the effect of reducing fruit drop loss and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The structure of the present invention will be described in further detail below in conjunction with the drawings.

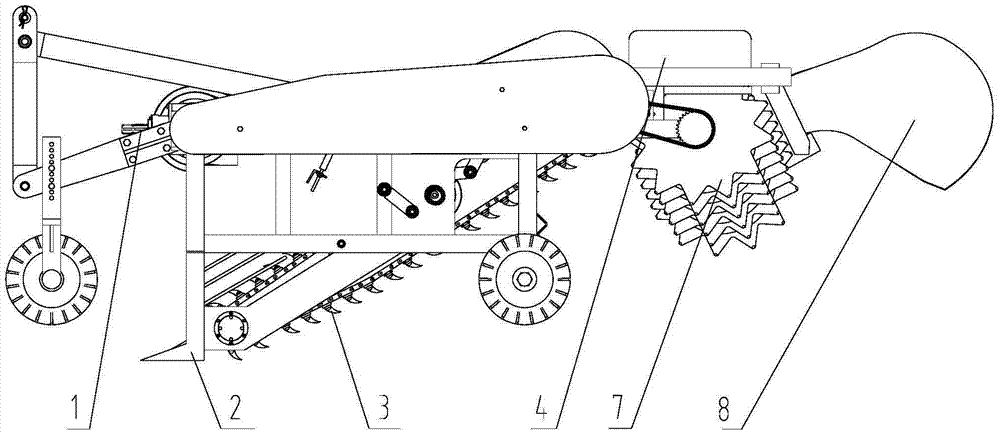

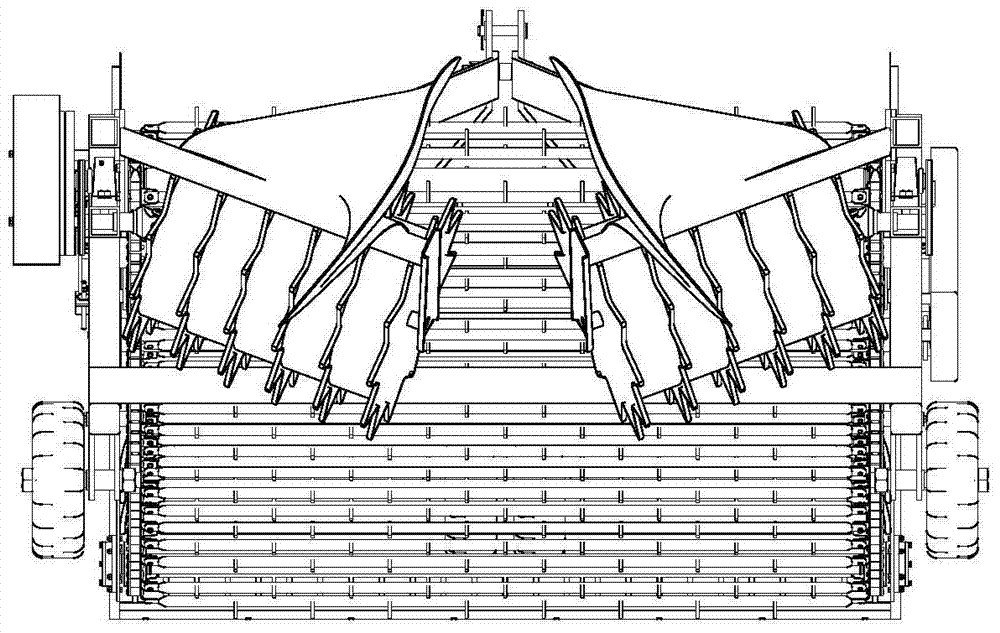

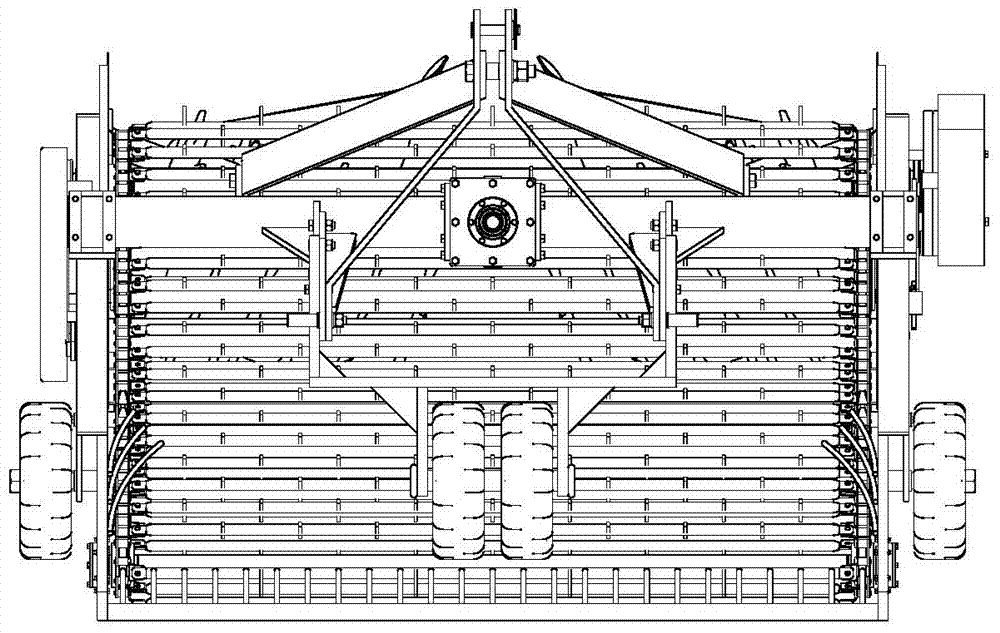

[0035] A small creeping peanut digging and harvester used for mulching planting. It is suspended by a three-point traction frame to form a horizontal rectangular frame. Two vertical poles are extended vertically on the left and right sides of the front end of the frame, and the lower ends of the vertical poles are arranged horizontally An excavating shovel 2 with a pointed tip facing forward, from the excavating shovel 2 to the rear crossbar of the rectangular frame, a toothed conveyor chain 3 is arranged from the lower front to the rear and upper; behind both sides of the toothed conveyor chain 3 Each part is equipped with a guide plate 4;

[0036] Between the two left and right guide plates 4, a pair of toothed rotary cylindrical cylinders 7 are arranged:

[0037] The height of the rotating cylindrical barrel with teeth on both sides is equivalent to the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com