Cloth dyeing machine with symmetrical double spiral cloth grooves

A double helix, symmetrical technology, applied in the field of dyeing machines, can solve the problems of difficult assembly of the helix, inconvenient operation, uneven pressure, etc., and achieve the effect of expanding the efficiency of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

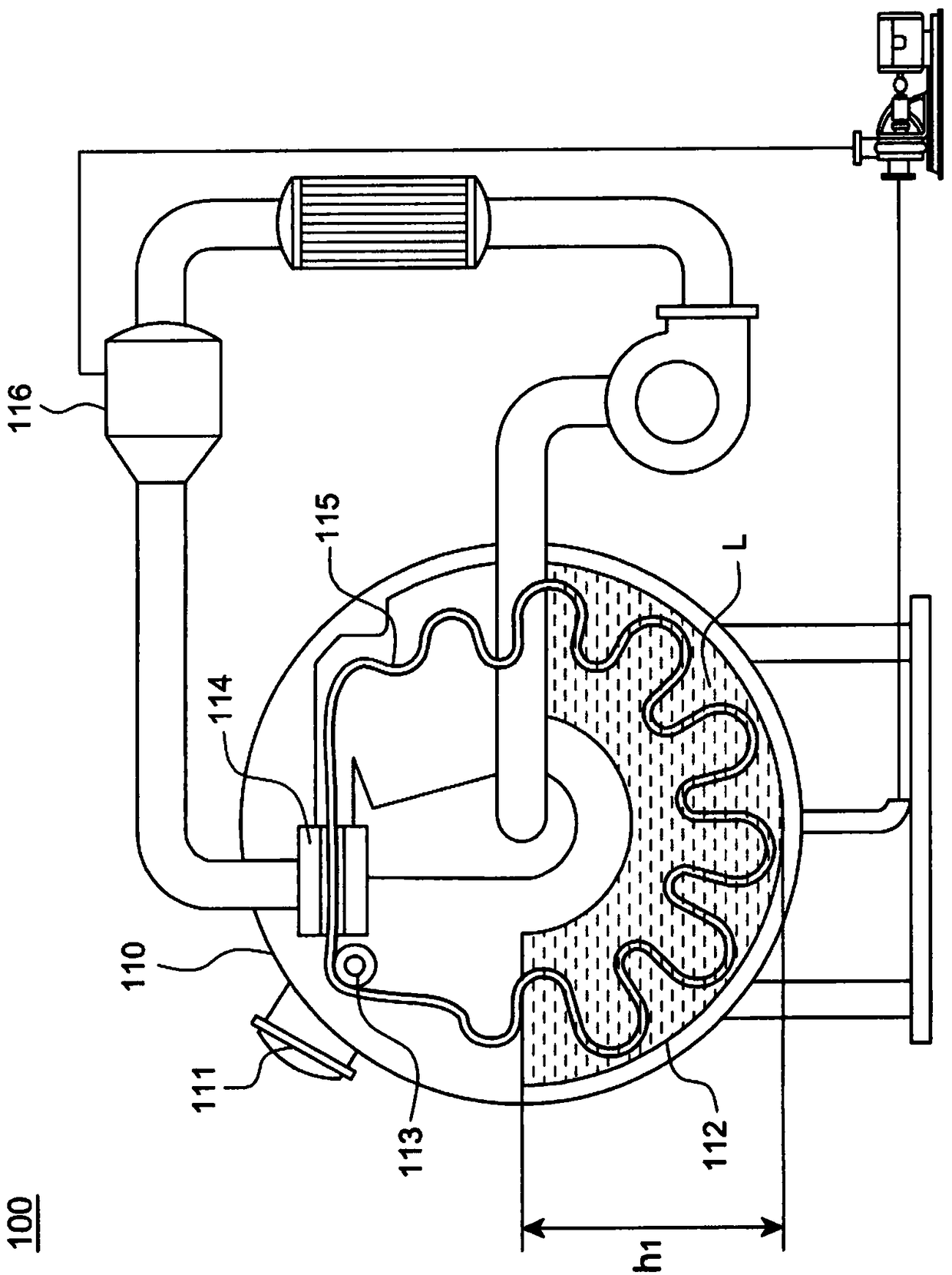

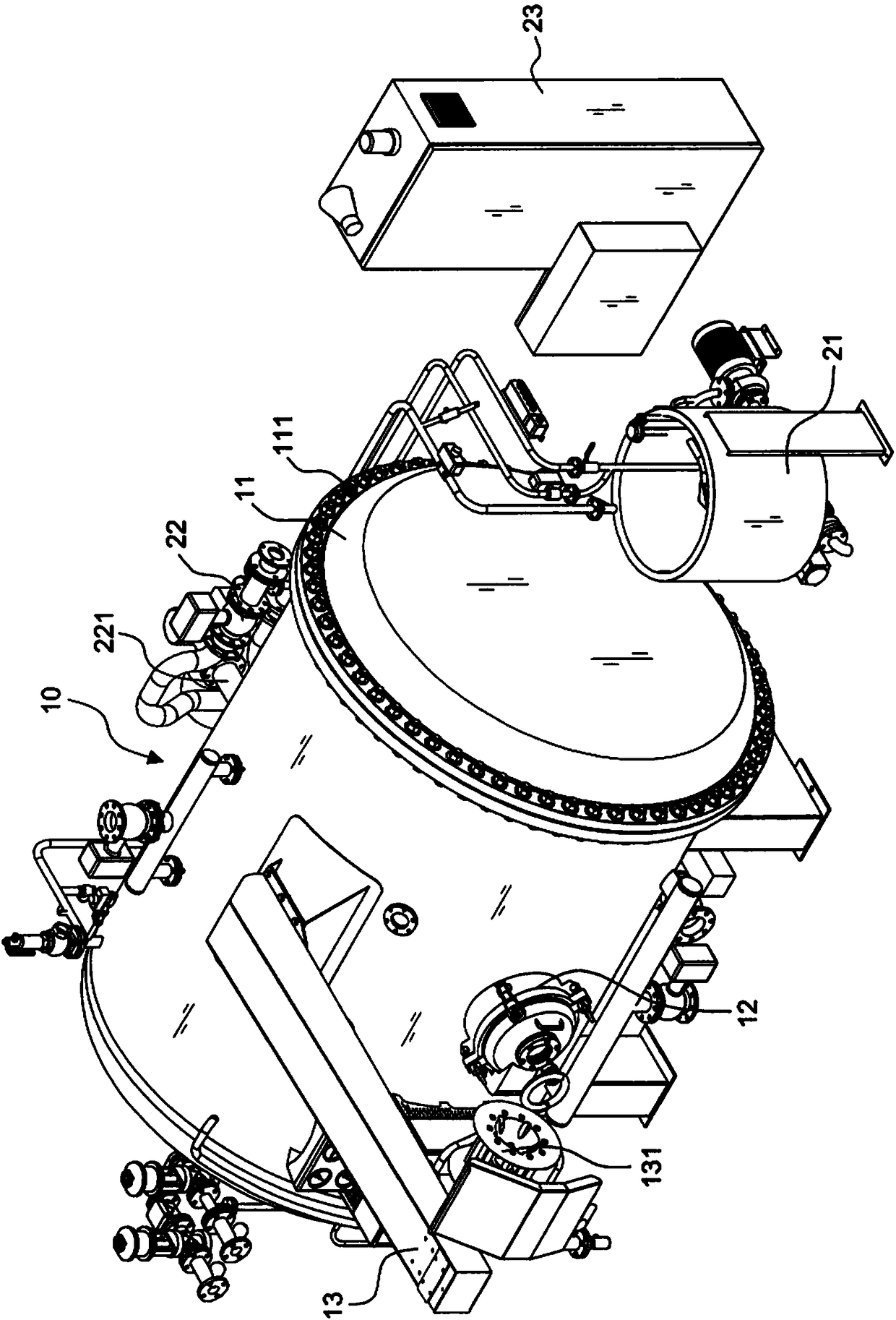

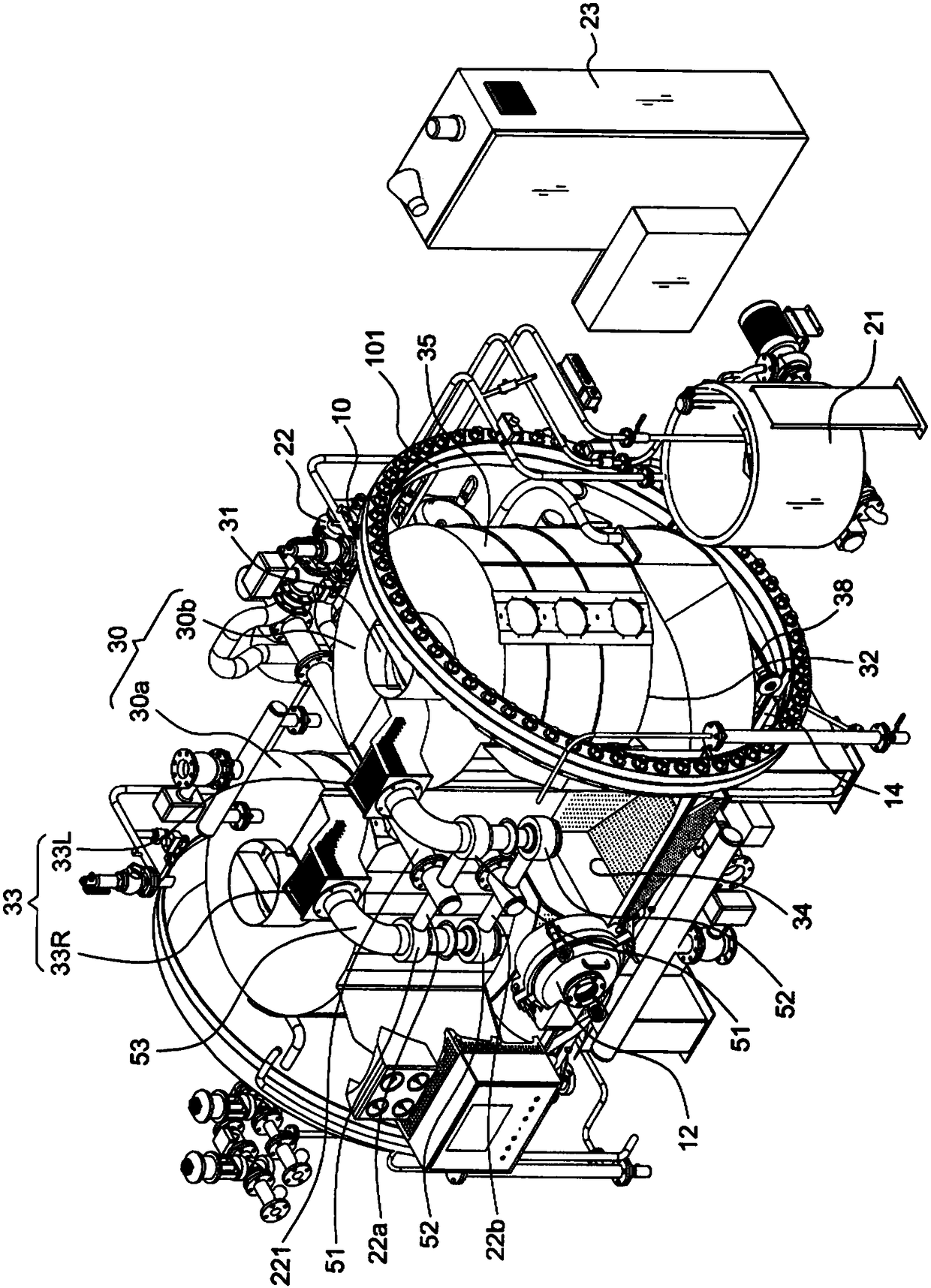

[0081] First, see Figure 2 to Figure 3C Shown is the appearance structure of its fabric dyeing machine in the present invention, comprising: a body 10, in order to accommodate cloth and dyeing liquor to carry out dyeing operation, this body 10 front side has a cloth inlet 12, and A cloth guide frame 13 placed above the cloth inlet 12, and the outer end of the cloth guide frame 13 can be provided with a runner 131 or as Figure 10 It can be implemented with two runners 131 as shown, so as to drive the cloth to be inserted and taken out smoothly from the cloth inlet 12; in addition, on the outside of the body 10, a dye injection mechanism 21 and a dyeing mechanism 21 are provided. Liquid input mechanism 22, this dye solution input mechanism 22 has an outlet pipeline 221, inlet pipeline 222 and pump 223 ( Figure 5 Shown); and apply a control mechanism 23 and heat exchanger 40 (such as Figure 3C As shown), under the dyeing process conditions of required heating or cooling, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com