Telescopic arm internally provided with three hydraulic cylinders and used for lorry-mounted crane

A technology of truck-mounted cranes and telescopic arms, which is applied in the field of telescopic arms, can solve problems such as complex assembly, easy damage, and heavy workload, and achieve the effects of reduced wear, compact overall structure, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

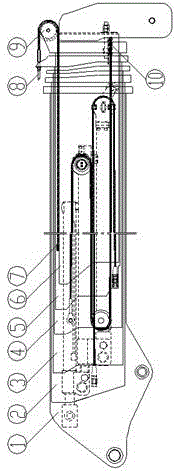

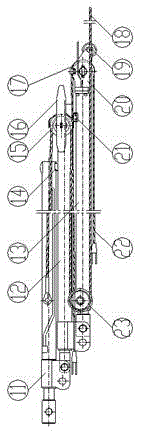

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] Such as figure 1 with figure 2 As shown, the telescopic boom for the truck-mounted crane with built-in three hydraulic cylinders includes the basic boom 1, the first telescopic boom 2, the second telescopic boom 3, the third telescopic boom 4, the fourth telescopic boom 5 and the fifth The joint telescopic arm 6 also includes a first telescopic oil cylinder 11, a second telescopic oil cylinder 12, a third telescopic oil cylinder 13, a telescopic cable 8, a recovery cable 18 and a rope row 22,

[0016] The head of the cylinder rod of the first telescopic oil cylinder 11 is fixed on the afterbody of the basic arm 1, and the cylinder afterbody of the first telescopic oil cylinder 11 is fixed on the afterbody of the first telescopic arm 2;

[0017] The cylinder rod head of the second telescopic oil cylinder 12 is fixed on the tail of the first telescopic oil cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com