Rotary threshing device with inner roller and outer roller for coarse cereal crops

A technology of drum rotation and threshing device, which is applied in the field of agricultural machinery, can solve the problems of grain damage and cleaning, difficulties, etc., and achieve the effect of reducing short straw content, low slapping and rubbing speed, and eliminating entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

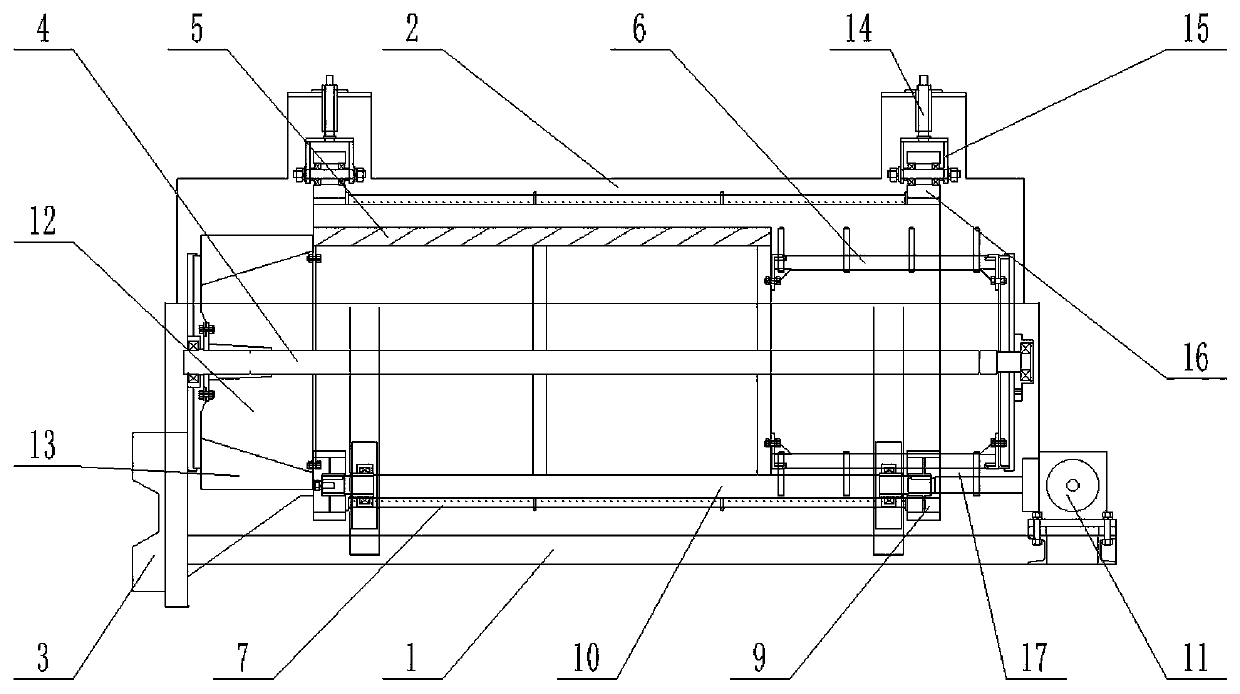

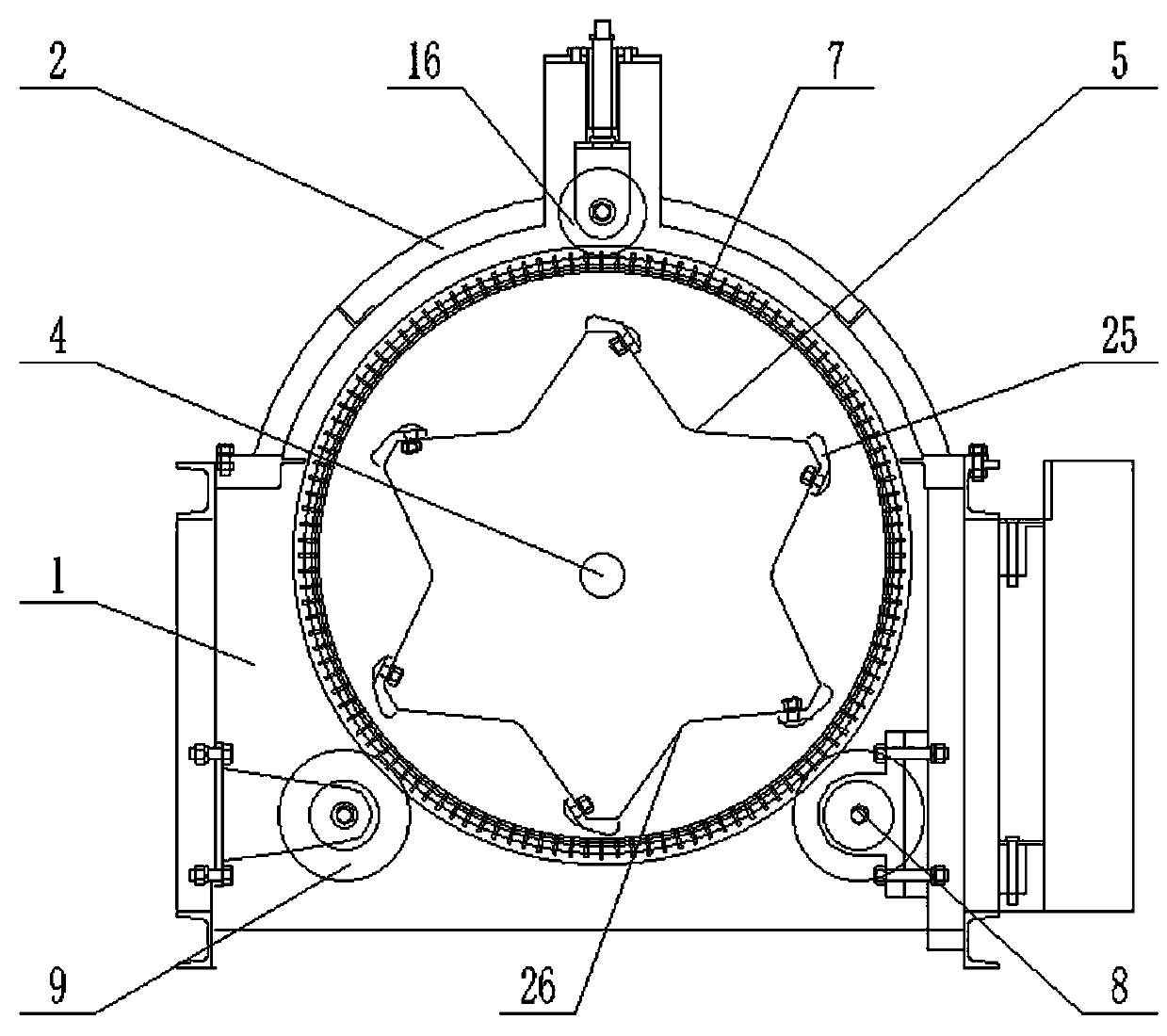

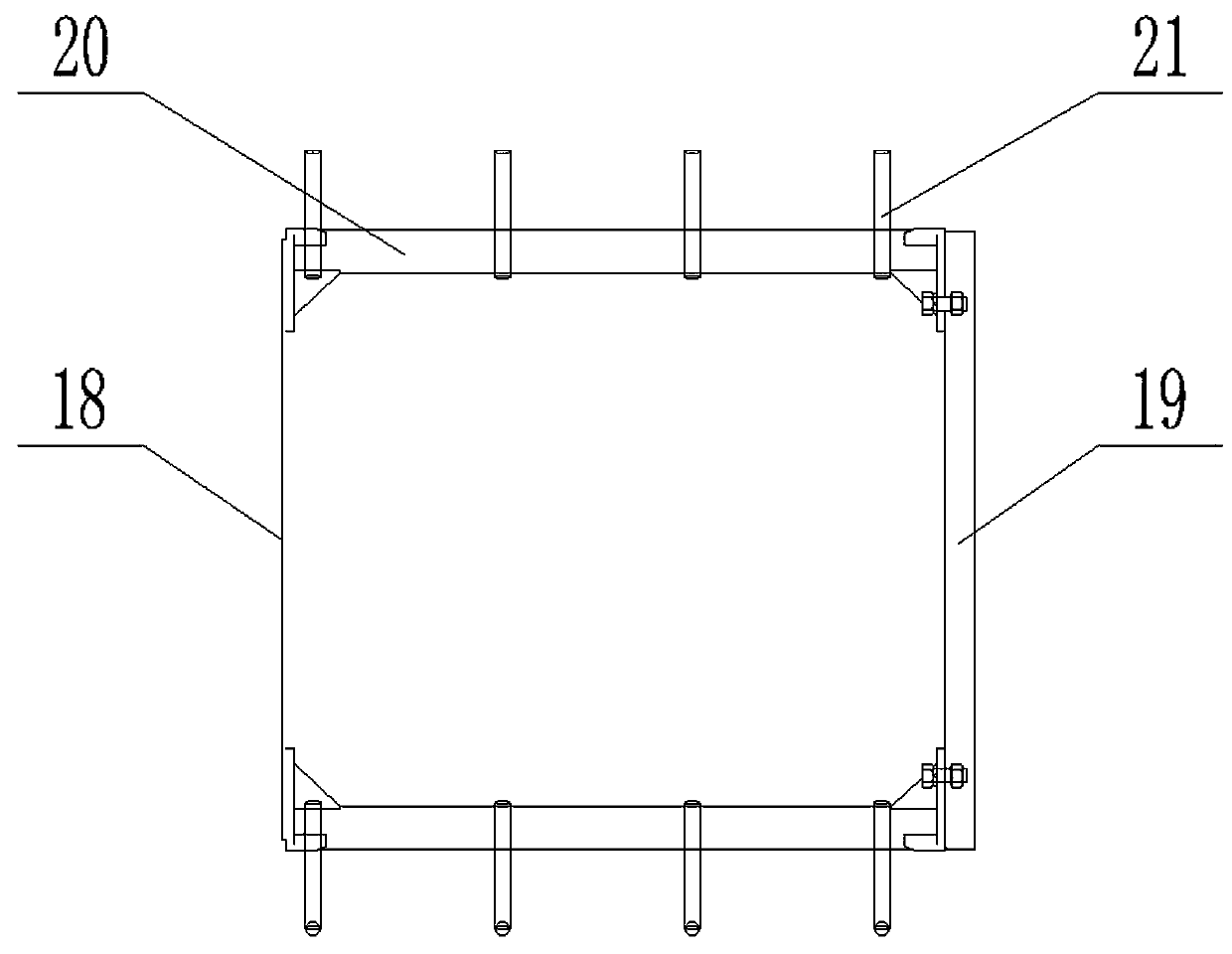

[0027] A rotary threshing device with inner and outer drums for miscellaneous grains, comprising a box-type frame 1, the top of the box-type frame 1 is provided with a top cover 2 with an arc-shaped inner wall, and the lower part of the front end of the box-type frame 1 is provided with a feeding port 3 , the box-type frame 1 is provided with a main shaft 4 that runs through its front and rear side walls, and the main shaft 4 is fixed with a screw feeding device located in the box-type frame 1 and distributed left and right, a grain bar threshing drum 5 and a nail tooth threshing drum 6 , the bar threshing cylinder 5 is provided with a grid cylinder 7 which is eccentric up and down with it, and the left and right sides of the bottom of the grid cylinder 7 are provided with a support wheel 8 and a friction wheel 9 which are close to its outer wall, and the center of the friction wheel 9 is provided with a transmission A shaft 10, the rear end of the transmission shaft 10 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com