Soft-smooth-warming home-textile blanket fabric and production method thereof

A production method and technology for home textiles, applied in the field of textile industry, can solve the problems of strong contact cold feeling, large cooling property of bamboo fiber blanket, large thermal conductivity of bamboo fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120] The present invention will be further described in detail in conjunction with specific embodiments below, so as to make the advantages of the present invention more obvious. It should be understood that the content therein is only used for illustration, rather than limiting the protection scope of the present invention.

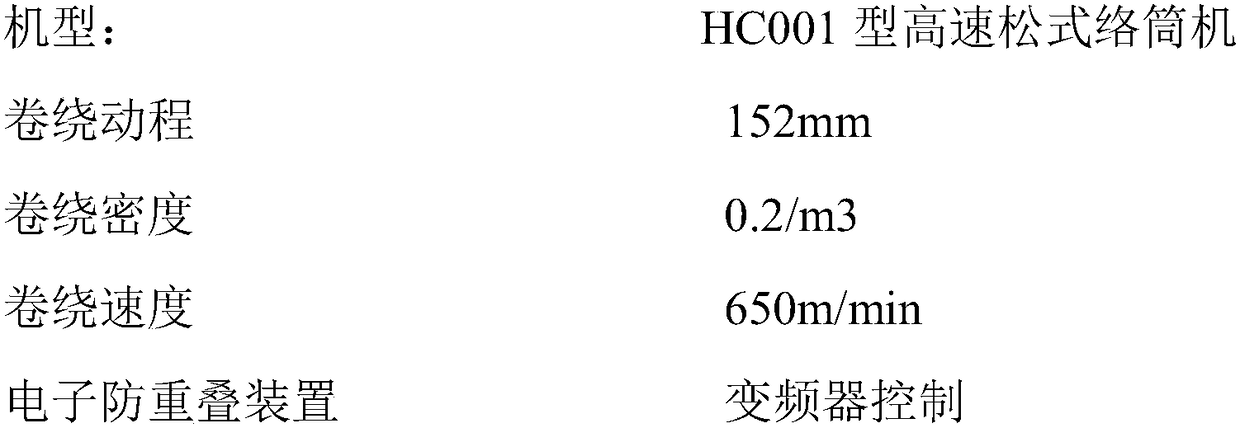

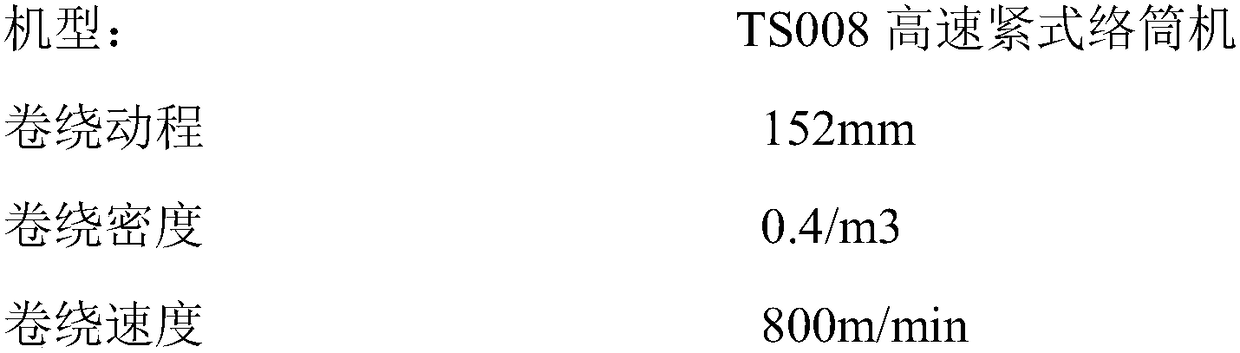

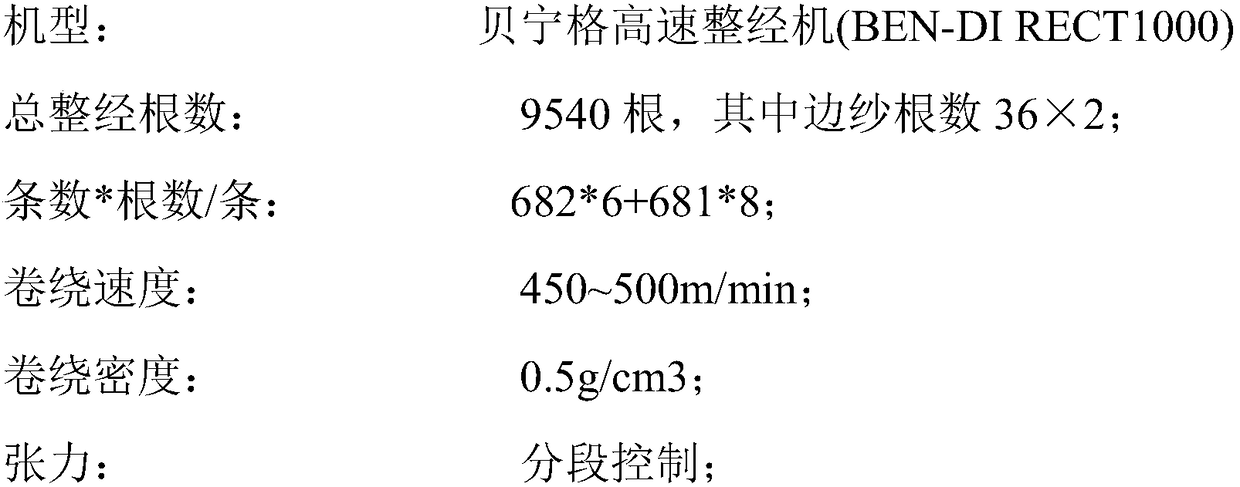

[0121] The specific product process is as follows:

[0122] 1. Product specifications

[0123] Width 269.2cm, compact spinning Meiyabi A70 / R30 21 S / 2 match × bamboo fiber 21 S / 2, warp and weft density 354.5 threads / 10cm×165 threads / 10cm, 2 / 2 jacquard fabric.

[0124] 2. Production process

[0125] 1. Spinning process

[0126] Warp yarn: compact spinning Meiyabi A70 / R30 21 S / 2

[0127] [Meiya Biacrylic: FA002A type plucking machine → A006B type automatic cotton blending machine → FA111 single roller cleaning machine → FA046 vibrating cotton feeder → FA141A single hand lapping machine → A186F carding machine → JWF1310 pre-merging] and 【Viscose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com