Harvesting machine and harvesting platform thereof

A harvester and header technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of complex structure and large size of the header, and achieve the purpose of reducing the size of the header, simplifying the structure, and reducing harvest losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

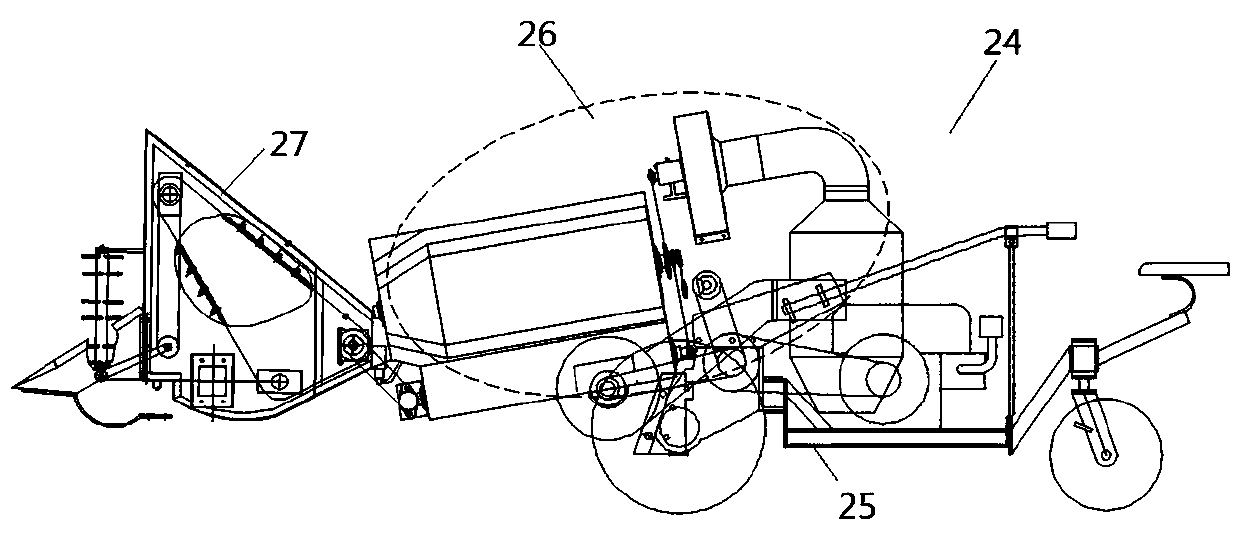

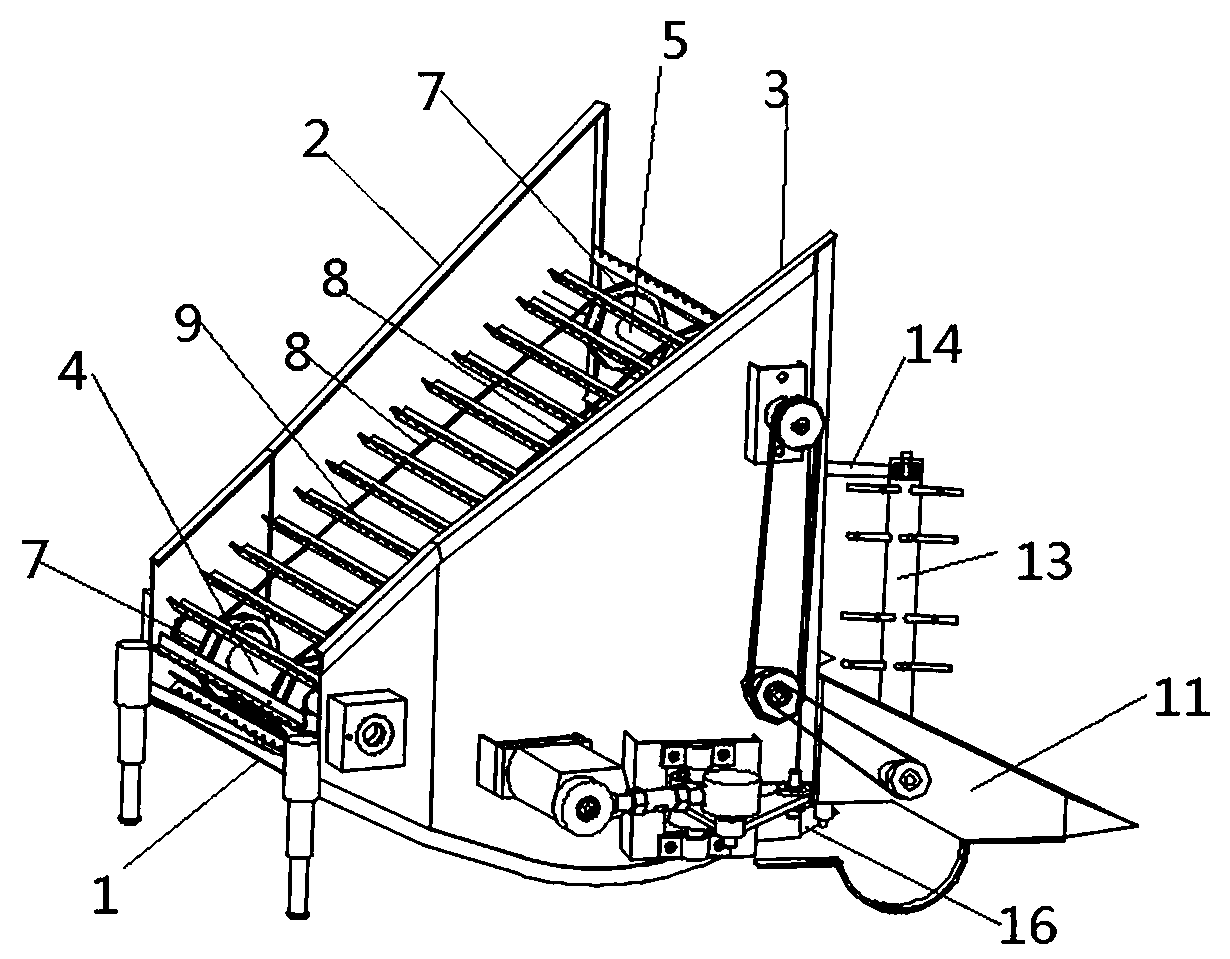

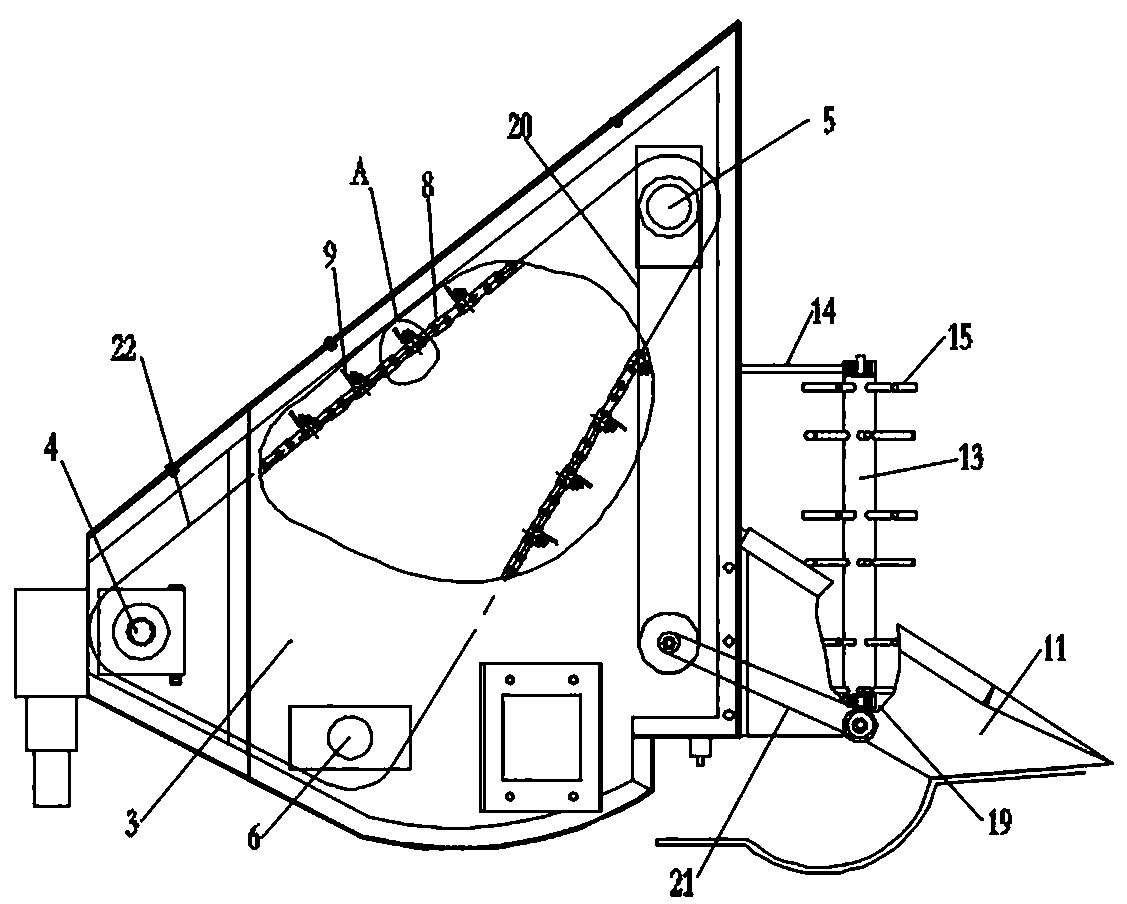

[0058] Such as figure 1 Shown is the overall structure diagram of the harvester 24, the harvester 24 includes a walkable harvester frame 25 and a threshing and cleaning system 26 arranged on the harvester frame 25, and also includes a The harvester header 27, the harvester 24 is also provided with a driving device that drives the harvester header 27 work; as Figure 2-3 As shown, the specific structure of the harvester header 27 is shown, and the harvester header 27 includes a support housing with a bottom support wall 1, a left support wall 2 and a right support wall 3, and the left support wall 2 and the right support wall 3 It is arranged on the bottom support wall 1 at intervals along the left and right sides, and the lower part of the harvester header 27 front side is provided with a cutter assembly 16, and the cutter assembly 16 is used for crop stubble cutting.

[0059] On the lower side of the rear end of the support housing, there is a drive shaft 4 that is rotatably...

specific Embodiment 5

[0069] The specific embodiment 5 of the harvester of the present invention differs from embodiment 1 in that the flexible scraping strip is a long strip with a rectangular cross section. Bolts on the side walls of the tank are fixed to the flexible scraping strips. Such setting simplifies the structure of the flexible scraping strip as a consumable part, reduces its manufacturing cost, and facilitates low-cost replacement of the flexible scraping strip in the later stage.

[0070] In other embodiments, in other embodiments, a separate motor can be used to drive the auxiliary reel roller. At this time, there is no need to set the reversing gear set and the transmission structure between the upper transmission shaft, and directly make the output shaft of the motor and the auxiliary reel roller Wo roller transmission connection; in other embodiments, the first transmission wheel is arranged on the driving shaft, and the second transmission wheel is arranged at the upper middle po...

specific Embodiment

[0073] The specific embodiment of the harvester header of the present invention: the specific structure of the harvester header is the same as the structure of the harvester header adopted in the above-mentioned harvester embodiment, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com