Green soybean harvesting machine

A harvester and storage box technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of low harvesting efficiency, troublesome picking operations, and falling to the ground, etc., to improve the harvesting rate and reduce the drop of pods. , Harvest loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

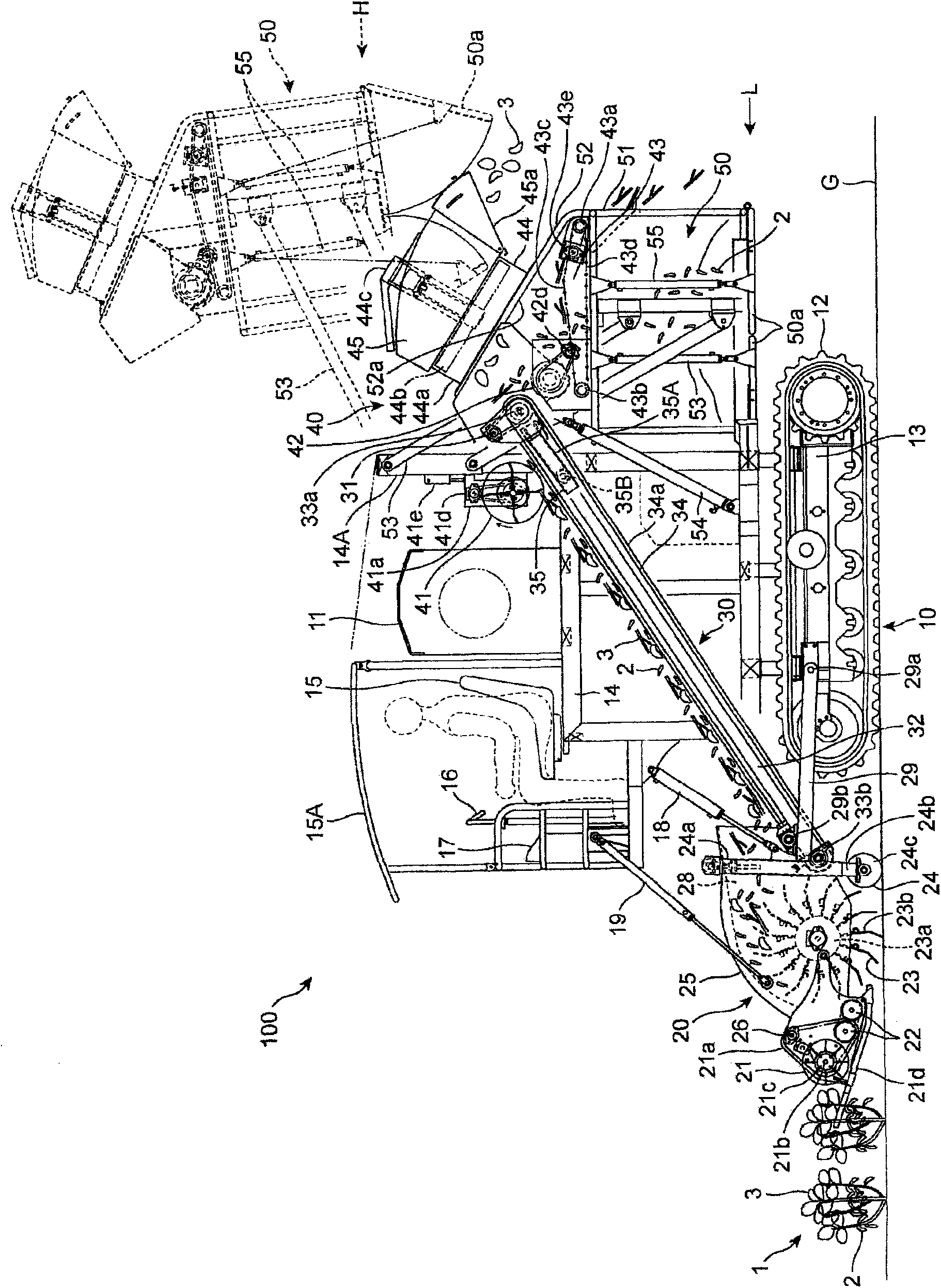

[0029] Such as Figure 1-Figure 6 Said; several rows of edamame grown in the ground, the height of the edamame when harvested is 60-70 cm,

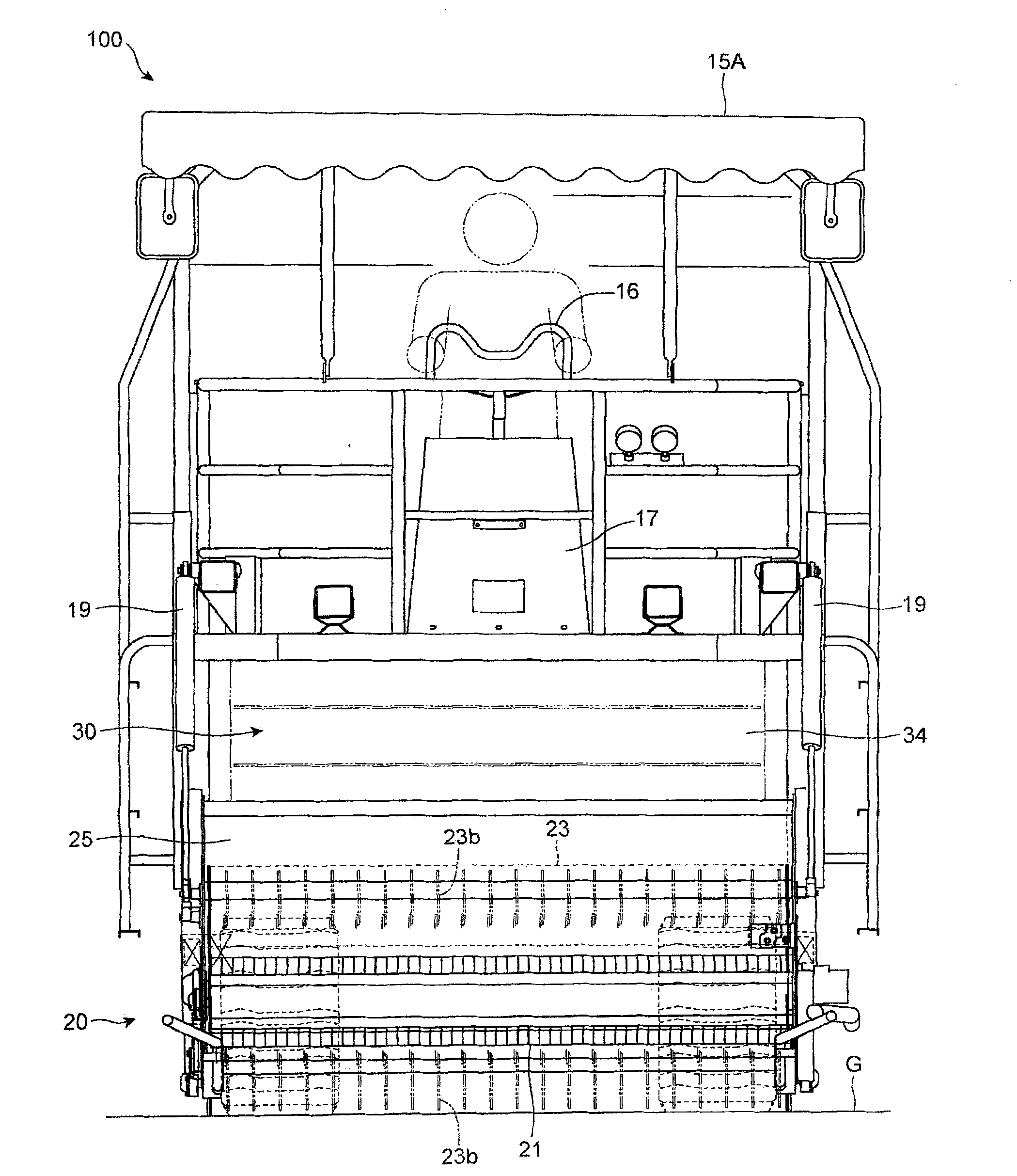

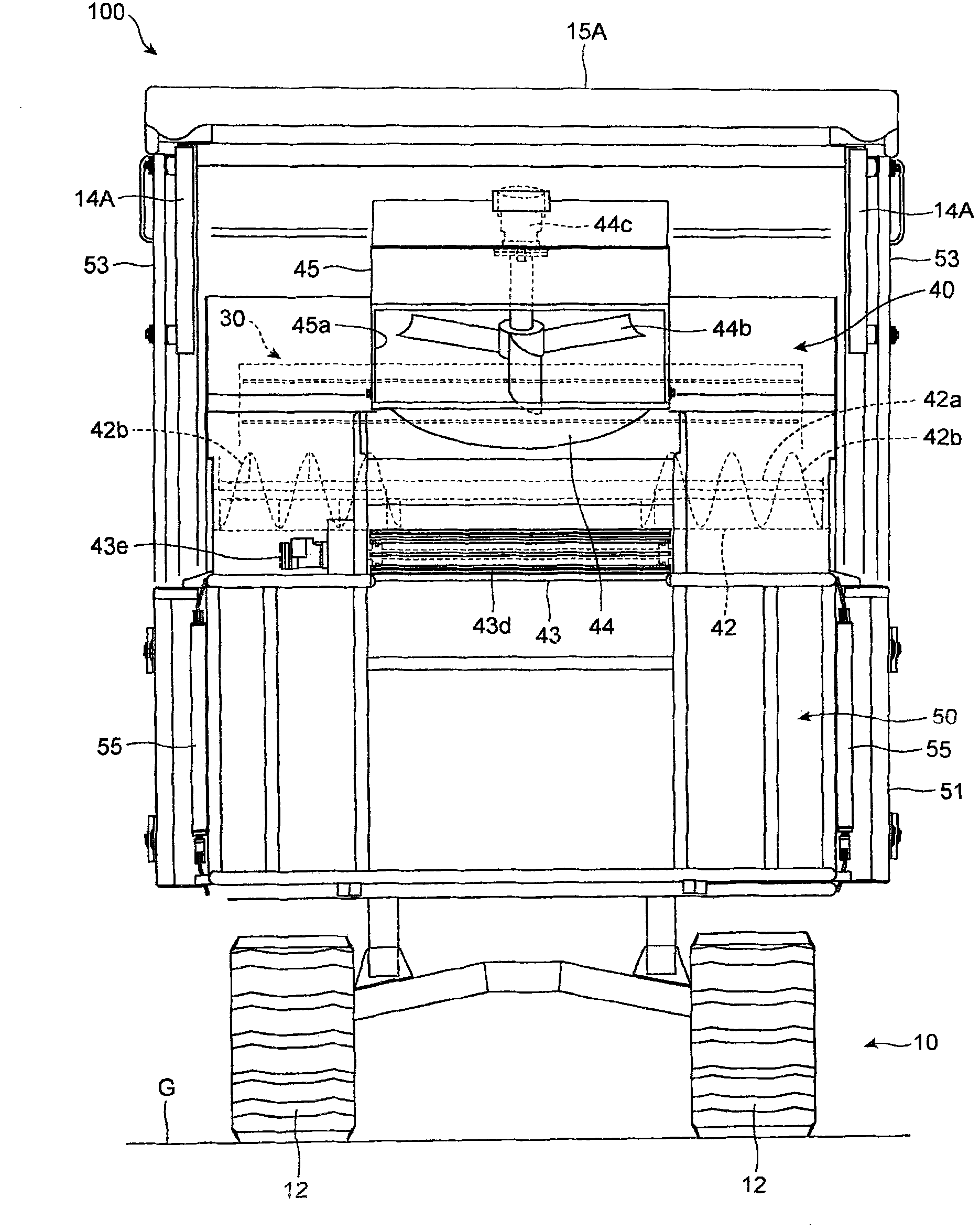

[0030] The soybean harvester 100 includes a traveling device 10, a picking device 20, a conveyor belt 30, a sorting device 40, and a storage box 50.

[0031] The driving device 10 is hydraulically driven by the engine 11, and the driven left and right crawlers are equipped with upper and lower bodies, and the left and right crawlers 12 can run on one ridge or across several ridges in the field. More specifically, when the ridge and the ridge are separated by 1.2 meters and the length is 50-60 meters, you can harvest while walking. The cab 15 and the steering wheel 16 are installed in the front of the upper frame 14 on the upper surface of the traveling device 10, and the control box 17 is installed in front of the steering wheel 16. The control box 17 is provided with an engine controller and a display instrument. In the cab 15, a joystick ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com