A header profiling device, its control system and method, and a harvester

A profiling device and control system technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of complex ridge surface environment, lack of horizontal profiling, and inaccurate adjustment of header height position, etc., to achieve Reduce the harvest loss of leafy vegetables and the effect of reducing the damage of cutting tools into the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

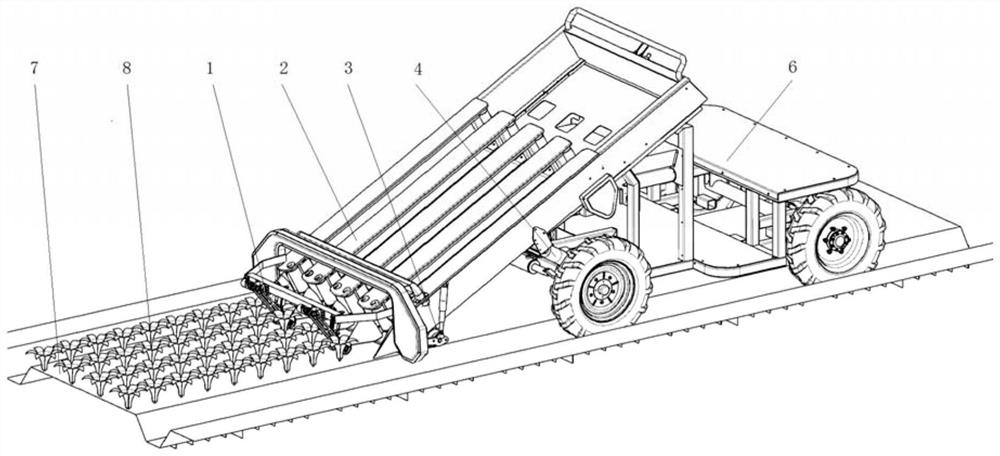

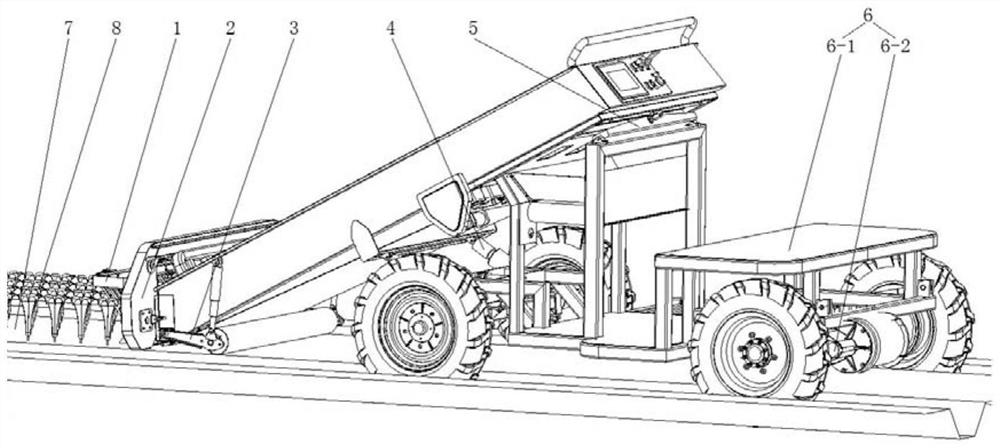

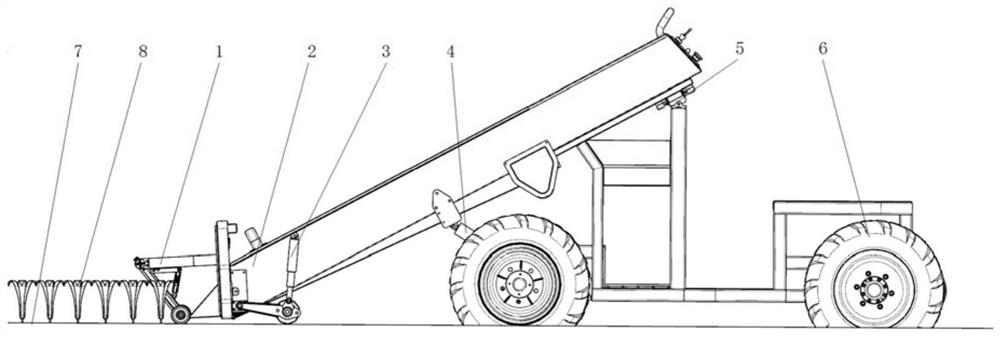

[0102] figure 1 , figure 2 , image 3 , Figure 4 It is a preferred embodiment of the header profiling device, the header profiling device includes a profiling detection assembly 1, a header profiling adjustment assembly 3, a header lifting execution assembly 4, a cutting The platform chassis hinge assembly 5 and the control system 9; the profiling detection assembly 1 is installed in front of the header 2; the header profiling adjustment assembly 3 is installed laterally and symmetrically on the front bottom of the header 2 end; two sets of the header lifting executive assembly 4 are laterally symmetrically installed between the header 2 and the chassis 6; the header chassis hinge assembly 5 is laterally symmetrically installed between the header 2 and the chassis 6 The rear end of the room; the control system 9 is respectively connected with the profiling detection assembly 1, the header 2, the header profiling adjustment assembly 3, the header lifting execution assembly...

example 1

[0111]Example 1: The header lifting actuator assembly 4 includes a tripping sleeve 4-1 and a header lifting actuator 4-2. The rod end of the tripping sleeve 4-1 is rotatably connected to the bottom of the header 2, and the hole end of the tripping sleeve 4-1 is slidably connected to the elongated end of the header lifting actuator 4-2 to form a straight line vice. The installation end of the header lifting actuator 4 - 2 is rotatably connected to the chassis 6 . When the extension end of the header lifting actuator 4-2 reaches the lowest position, a free floating telescopic state is formed between the header lifting actuator 4-2 and the tripping sleeve 4-1, that is, the The header lifting actuator 4-2 no longer exerts thrust on the trip sleeve 4-1; when the extension end of the header lifting actuator 4-2 reaches the highest position, the formed free-floating telescopic state becomes To support the fixed state, that is, the header lifting actuator 4-2 lifts the header 2 to a...

example 2

[0112] Example 2: The header lifting executive assembly 4 includes the header lifting actuator 4-2, and realizes the horizontal and vertical adjustment of the height of the header 2 through the hydraulic system 10, and the hydraulic system 10 includes Oil tank (10-1), filter (10-2), hydraulic pump (10-3), overflow valve (10-4), check valve (10-5), first electromagnetic reversing valve (10- 6), the second electromagnetic reversing valve (10-7), the hydraulic control check valve (10-8), the third electromagnetic reversing valve (10-9) and the throttle valve (10-10). The extension end of the header lifting actuator 4 - 2 is rotatably connected to the bottom of the header 2 , and the installation end of the header lifting actuator 4 - 2 is rotatably connected to the chassis 6 . When the header 2 of the harvester needs to be transported, the electromagnetic reversing valve 1 (10-6) is in the right working position, and the high-pressure oil enters the rodless cavity of the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com