Copying cutting platform for cutterhead of sugarcane harvester

A technology of profiling cutting and harvesting machine, which is applied in the direction of headers, harvesters, agricultural machinery and implements, etc., can solve the problems of high breakage rate and large loss of sugarcane harvesting, and achieves reduction of broken ends of sugarcane, low manufacturing cost, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

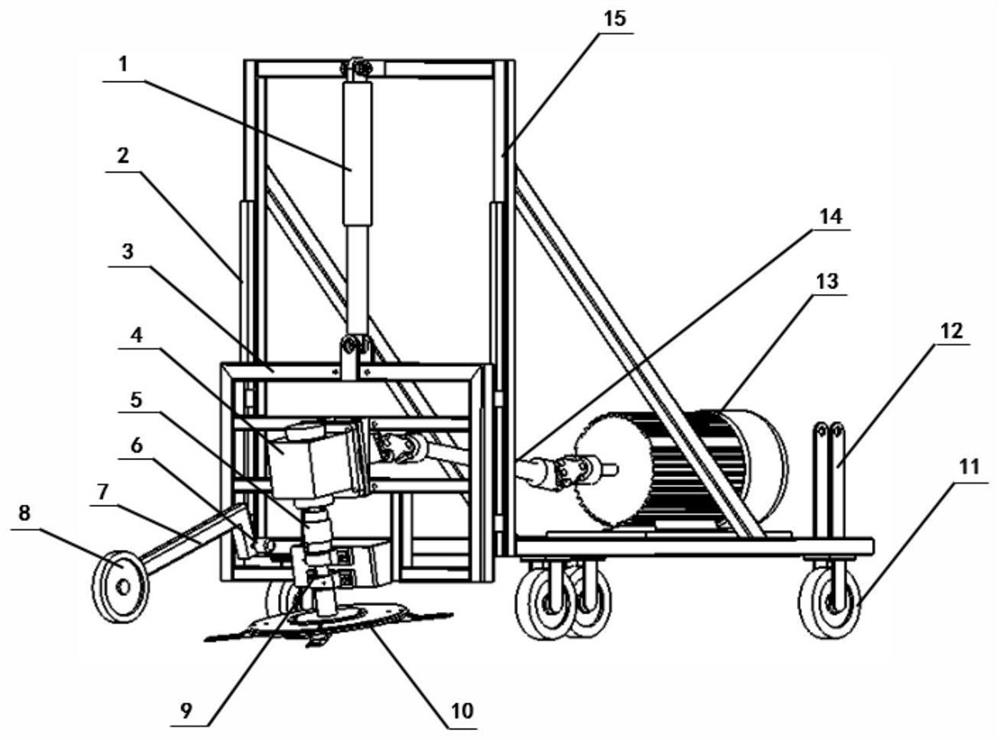

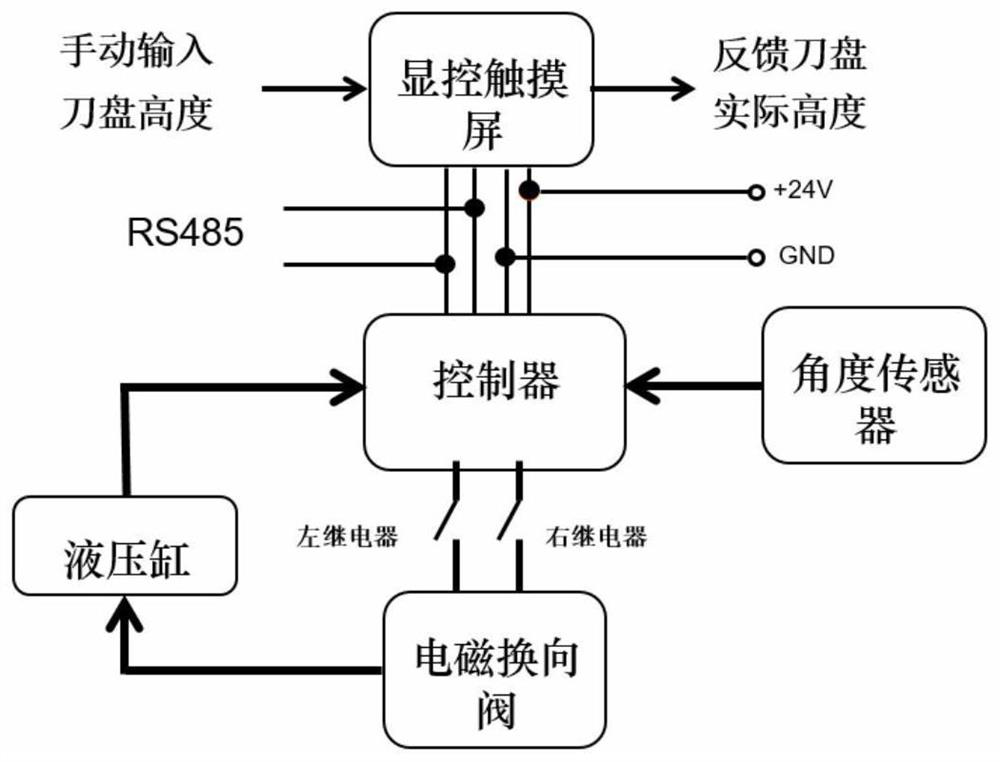

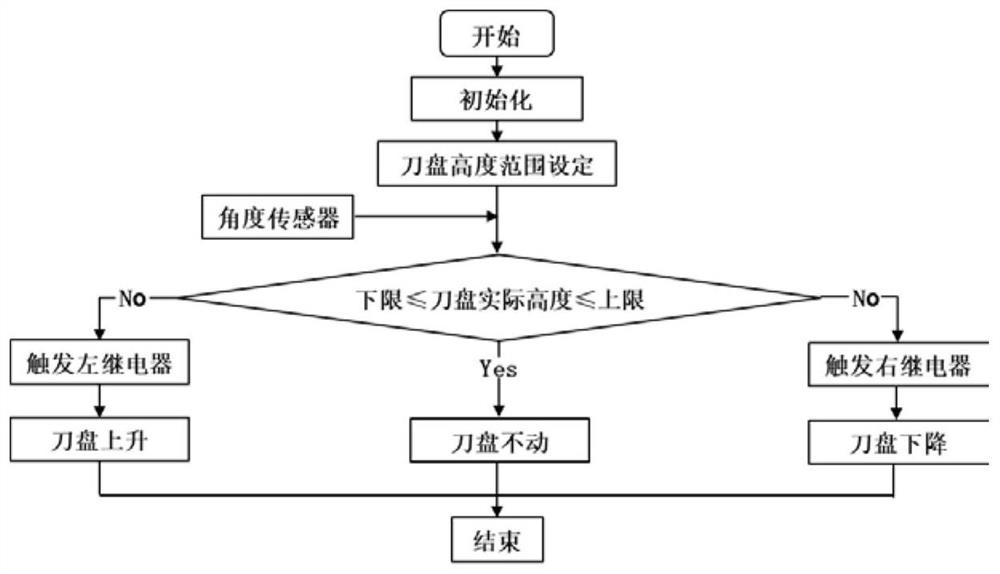

[0034] The following is attached Figure 1-3 The present invention is described in further detail.

[0035] Such as figure 1 As shown, the sugarcane harvester cutterhead profiling cutting platform is mainly divided into a cutterhead lifting system, a cutterhead drive system, a cutterhead height automatic adjustment control system and a frame 15;

[0036] The cutterhead lifting system is arranged on the two longitudinal beams at the front end of the frame 15; the cutterhead drive system is arranged on the bottom crossbeam of the frame 15 and is located at the rear end of the frame 15; the cutterhead height is automatically adjusted Control system is arranged on the right crossbeam of frame 15 obliquely.

[0037] The cutterhead lifting system includes: cutterhead cutting frame 3, two linear slide rails 2, profiling rod 7, profiling wheel 8, cutterhead shaft 9, cutterhead 10, right-angle steering gear 4 and elastic coupling 5 ;

[0038] The two linear slide rails 2 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com