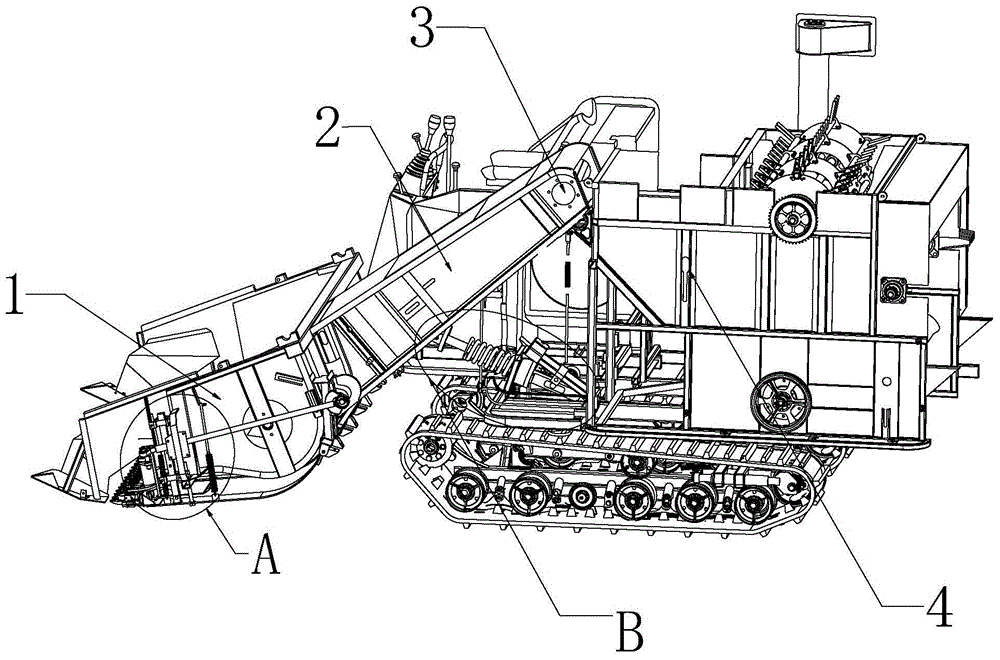

Floating header and a combine harvester comprising the same

A combine harvester and floating mechanism technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as shoveling, cat ear stubble, soybean mud stains, etc., to avoid missed cutting and shoveling, Effects of increasing productivity and reducing grain harvest losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

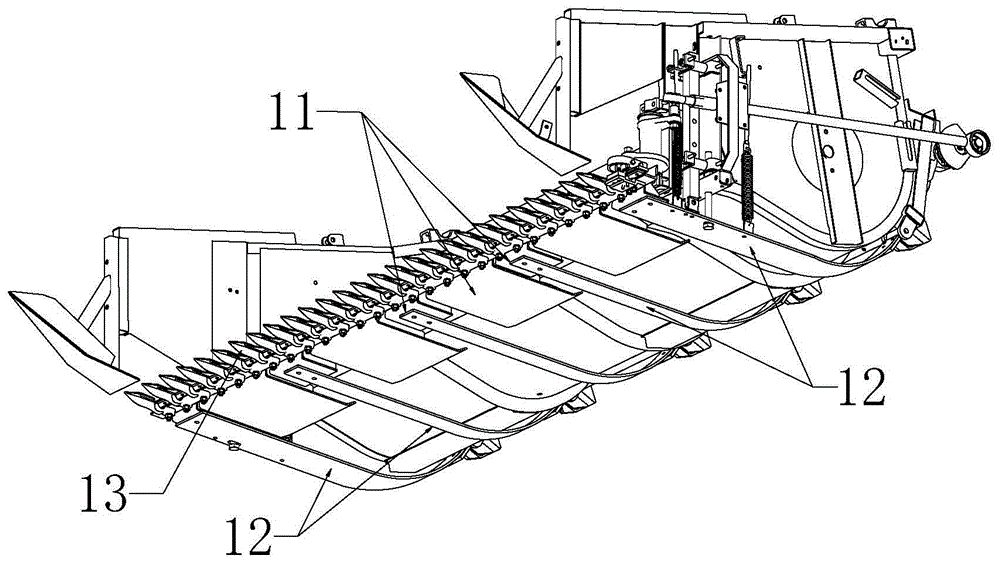

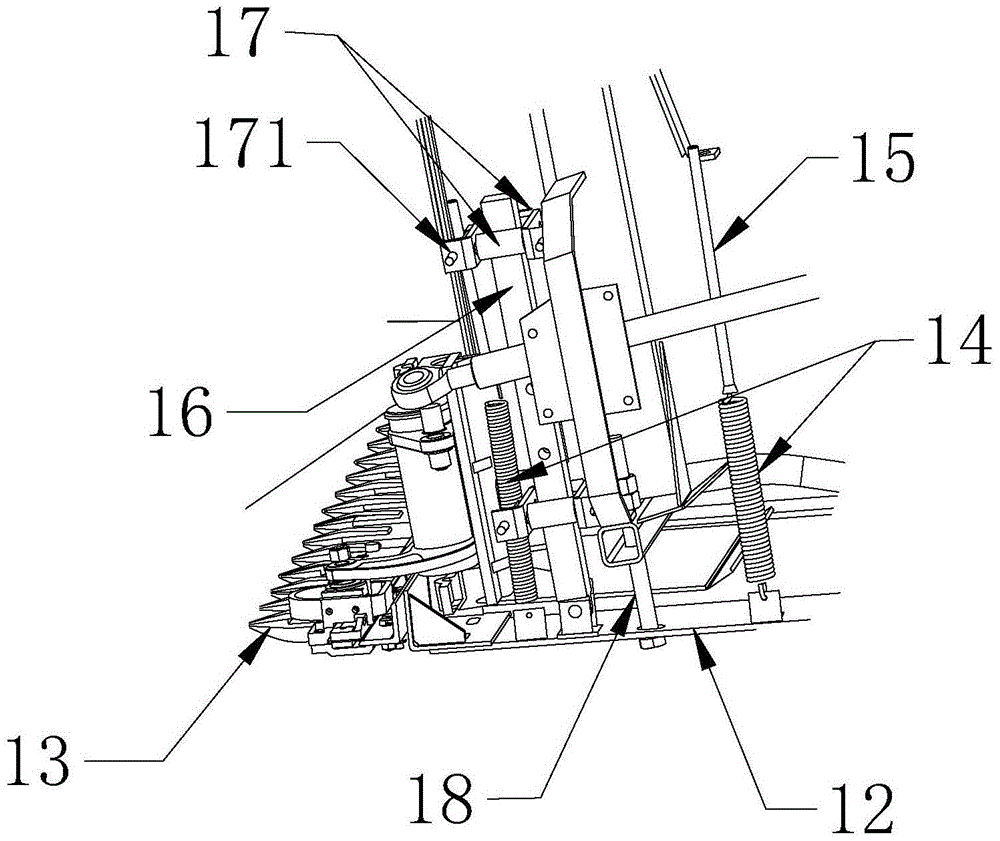

[0026] figure 2 It is the structural diagram of the header bottom of the present invention, image 3 for figure 1 Partial enlarged view of A, such as figure 2 and image 3 As shown, the floating header provided by the present invention includes a fine-tuning floating mechanism A formed by a slider group 11 located at the bottom of the header, a leaf spring group 12 and a cutter floating assembly; the slider group includes a large slider and a small slider, and the large slider Arranged at intervals with the small slide plate, the large slide plate and the small slide plate are fixed on the fixing frame of the cutter by bolts.

[0027] The fine-tuning floating mechanism A includes: a tension spring 14, a guide rod 16, a roller group 17; the slide group 11 includes several slide plates (i.e. a large slide plate and a small slide plate), and all slide plates are distributed in parallel and fixed on the fixed frame of the cutting knife 13 ;

[0028] Described leaf spring gr...

Embodiment 2

[0035] In this embodiment, on the basis of Embodiment 1, an adjustment mechanism 171 capable of adjusting the shaking range of the guide rod is added; specifically, the roller set 17 includes two rollers and an adjustment mechanism capable of adjusting the distance between the two rollers 171.

[0036] Due to the difference in terrain and land environment, the shaking range of header 1 is required to be different. Therefore, the present invention adjusts the distance between the two rollers through the adjustment mechanism 171, and then adjusts the shaking range of the guide rod through the distance between the two rollers. , so that the head of the harvester can better adapt to different terrains and geographical environments by limiting the guide rod to shake within an acceptable range, thereby better improving the productivity and efficiency of harvesting.

Embodiment 3

[0038] This embodiment is further improved on the basis of Embodiment 1 or Embodiment 2, that is, the stroke of the leaf spring 12 is adjusted by setting a stroke bolt 18; specifically, one end of the stroke bolt 18 passes through the leaf spring 12 is fixed by the screw head after the through hole, and the other end passes through the through hole of the lower frame of the header by two nuts on the frame of the header 1, and the travel bolt 18 is arranged near the guide rod 16.

[0039] Due to the difference in terrain and land environment, for example, the land with sand and the land with stones require different strokes for the header plate spring to move up and down. Therefore, the present invention adjusts the stroke of the plate spring 12 by setting the stroke bolt 18 , to better improve harvesting productivity and efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com