Header device of corn kernels harvester

A technology for harvesters and headers, which is applied to harvesters, harvesters, agricultural machinery and implements, etc., and can solve the problem of large volume and increased maintenance workload of the left-handed vertical conveying cylinder and the right-handed vertical conveying cylinder , affecting harvesting efficiency and other issues, to achieve the effect of simple structure, low manufacturing cost and improved harvest rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the drawings and embodiments.

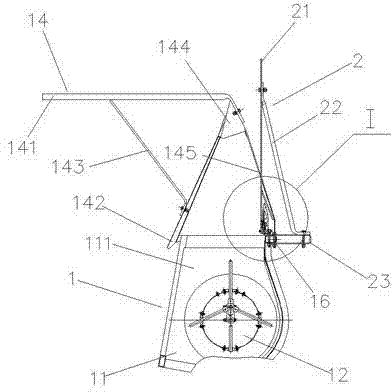

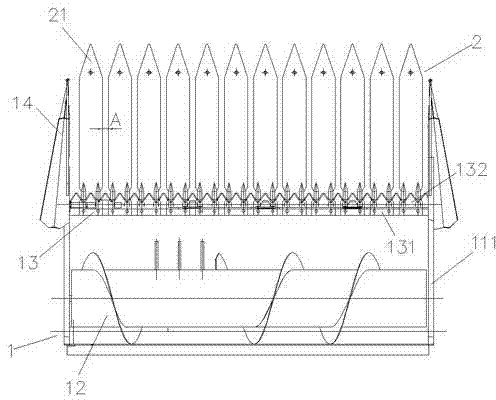

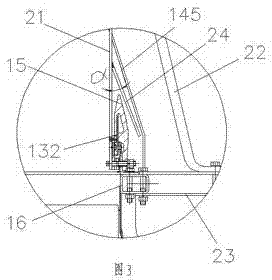

[0018] Such as Figure 1 ~ Figure 3 Said, the present invention includes a header combination 1 and a header suspension mechanism 2. The header combination 1 includes a header body 11, a header auger 12 arranged in the header body 1, and a header set on the front side of the header body 1. The movable knife assembly 13 and the crop dividers 14 respectively arranged at the two ends of the front side of the cutting platform body, the cutting platform auger 12 conveys the cut and fallen corn crops to the feed inlet direction of the cutting platform body 11. The movable knife assembly 13 is embedded in the blade guard 15 and includes a knife beam 131 and a plurality of movable blades 132 riveted side by side on the knife beam 131. The knife beam 131 drives the plurality of movable blades 132 to reciprocate on the upper side of the fixed blade. Shearing of corn crop stalks. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com