Tunneling machine

A technology of reducer and cutting unit, which is applied in the direction of cutting machinery, earthwork drilling and mining, etc. It can solve the problems of reduced shipments, insufficient undercover quantity, unloading, and poor receiving status, etc., and achieves the improvement of unloading status , increase shipments, increase the effect of cutting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

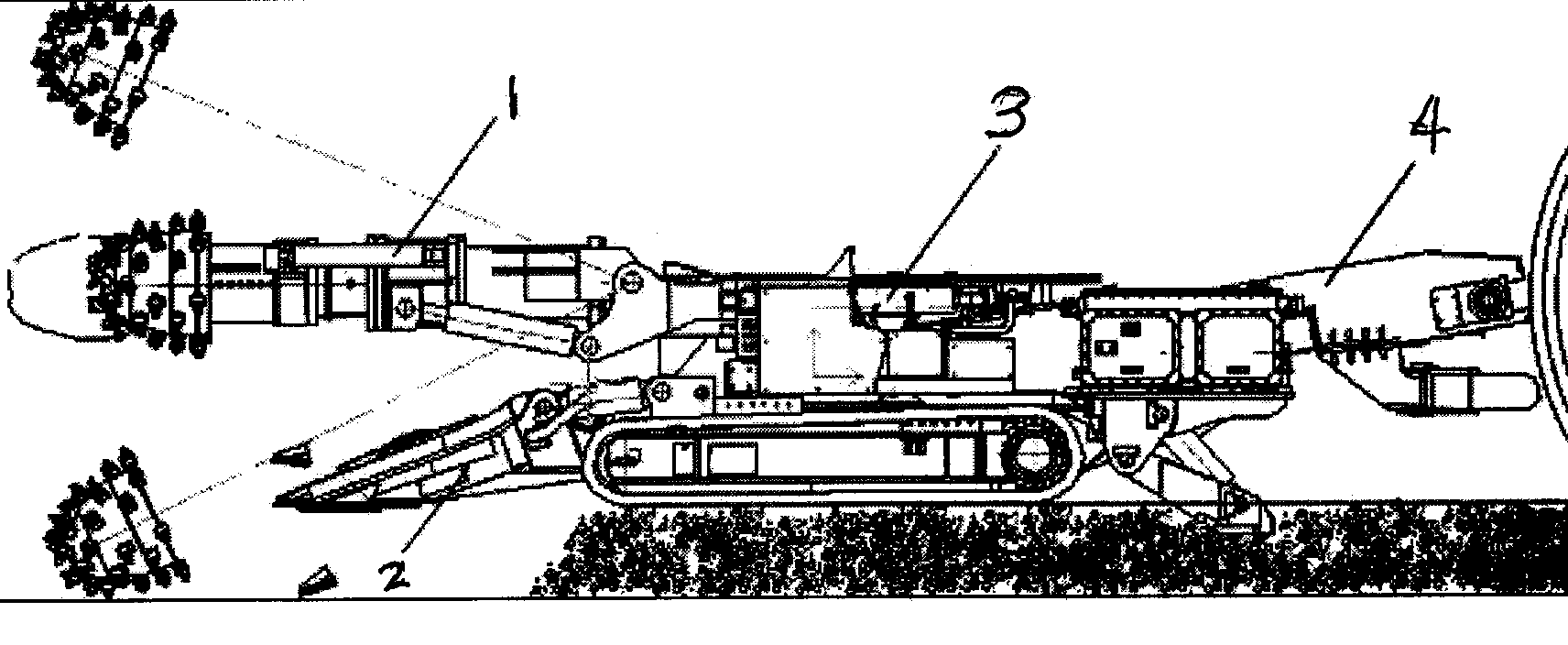

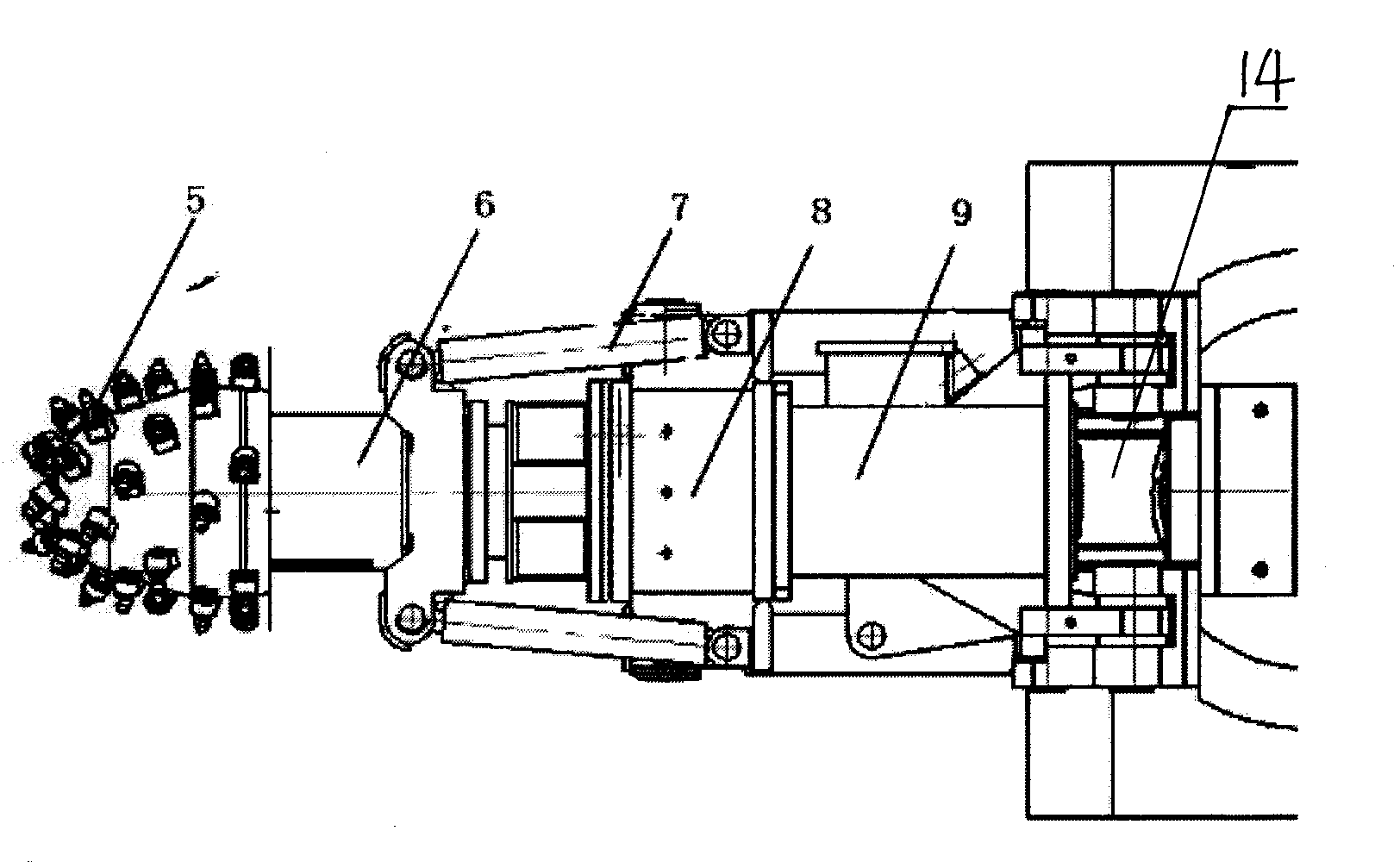

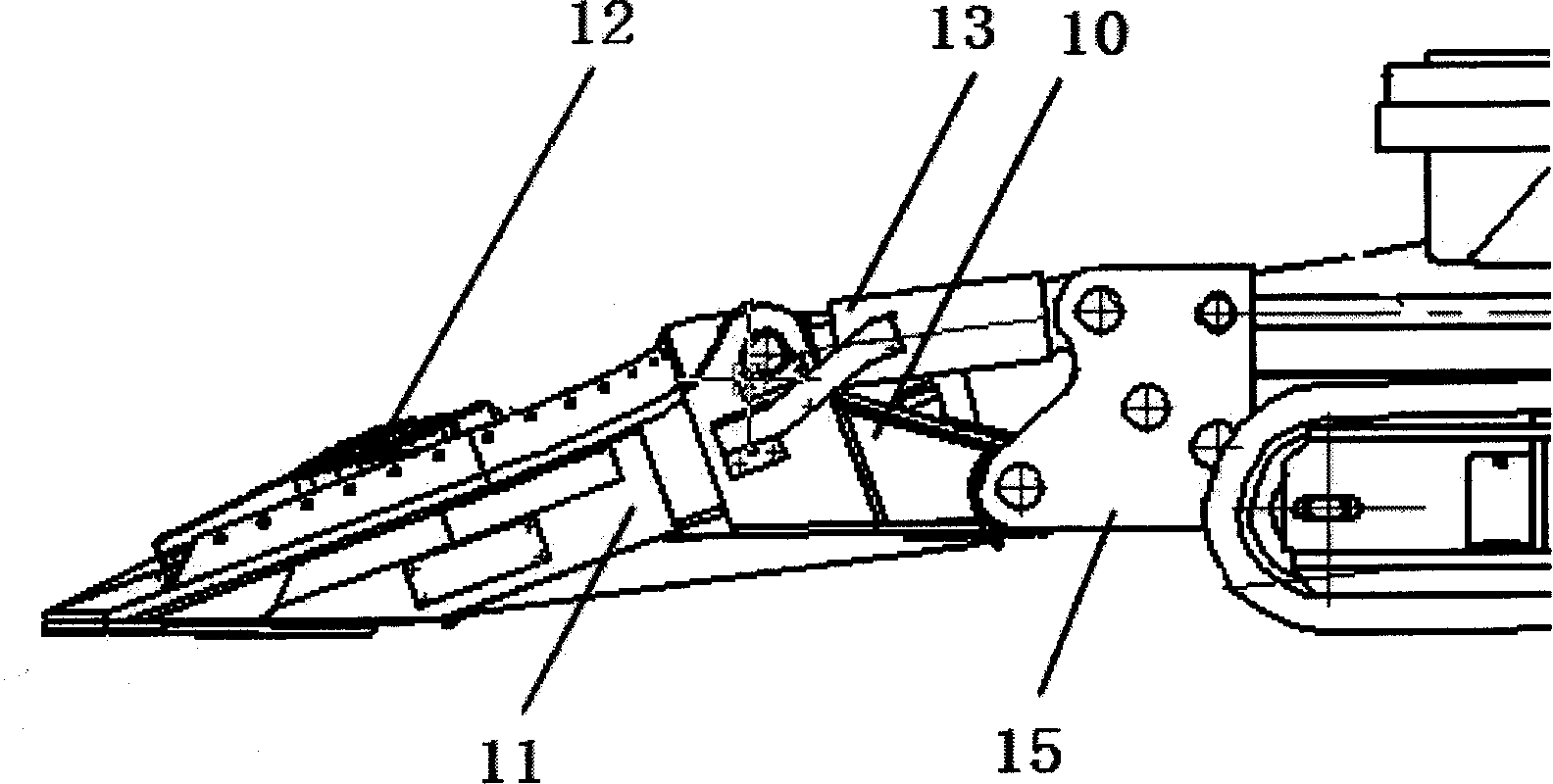

[0012] Such as figure 1 As shown in -4, the roadheader includes a cutting part 1, a shovel part 2, a body part 3, a transport part 4, a cutting head 5, a telescopic sleeve 6, a telescopic oil cylinder 7, a cutting speed reducer 8, and a cutting motor 9. Main shovel 10, side shovel 11, star wheel 12, shovel lifting cylinder 13, body frame 14, shovel telescopic frame 15, front groove 16 for first movement, rear groove 17 for first movement, connecting frame 18 for second movement, The cutting part 1 is composed of a cutting head 5, a telescopic sleeve 6, a telescopic cylinder 7, a cutting reducer 8 and a cutting motor 9, and the shovel part 2 is composed of a main shovel 10, a side shovel 11, a star wheel 12 and The shovel lift cylinder 13 is made up, the body part 3 is made up of the body frame and the shovel telescopic frame, the transportation part 4 is made up of a front groove 16, a rear groove 17 and a second connecting frame 18, the cutting head 5 and the cutting The red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com