Fuel gas tunnel kiln in use for producing foam glass

A foam glass and tunnel kiln technology, applied in glass production, glass molding, glass furnace equipment, etc., can solve the problems of high energy costs, achieve the effects of reducing production costs, reducing impacts, and increasing material cutting rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

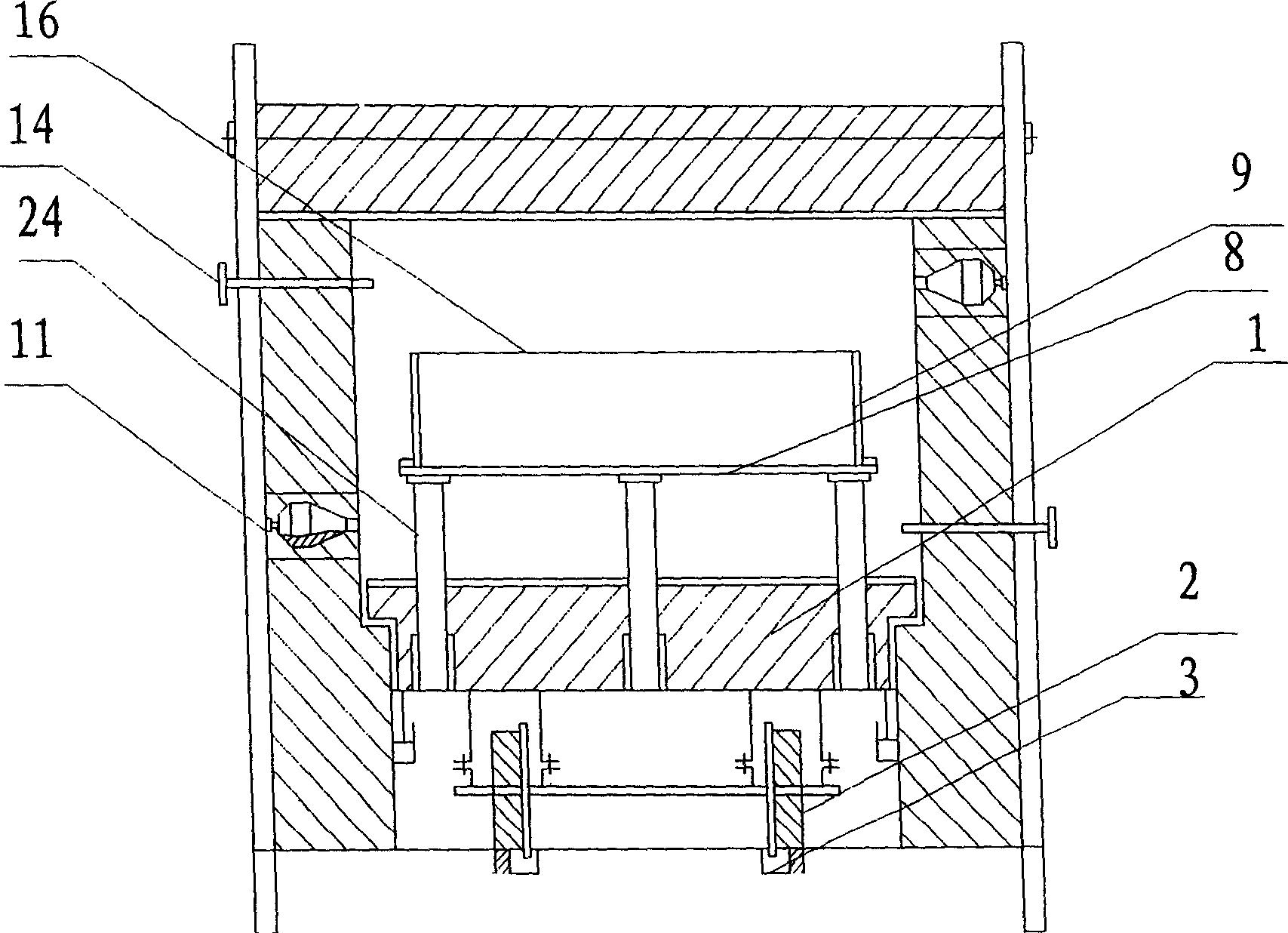

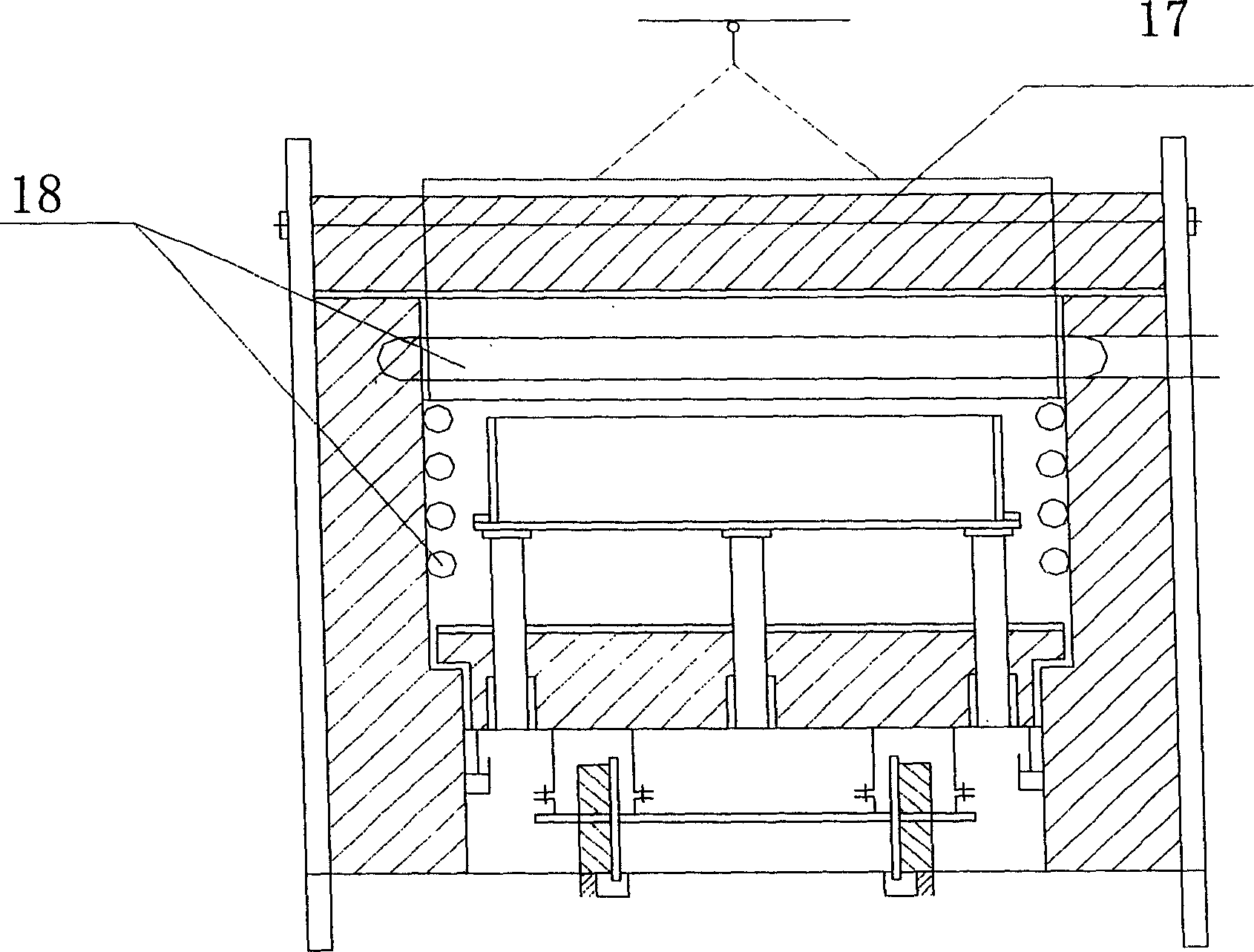

[0038] The kiln car 1 adopts the wheel 2 structure, so that the transmission movement resistance is small. The kiln car 1 is used as a transportation tool for the batch material, so that the batch material is processed according to the process, and the batch material is foamed to form porous foam glass. The wheels 2 of the kiln car 1 advance along the track 3 .

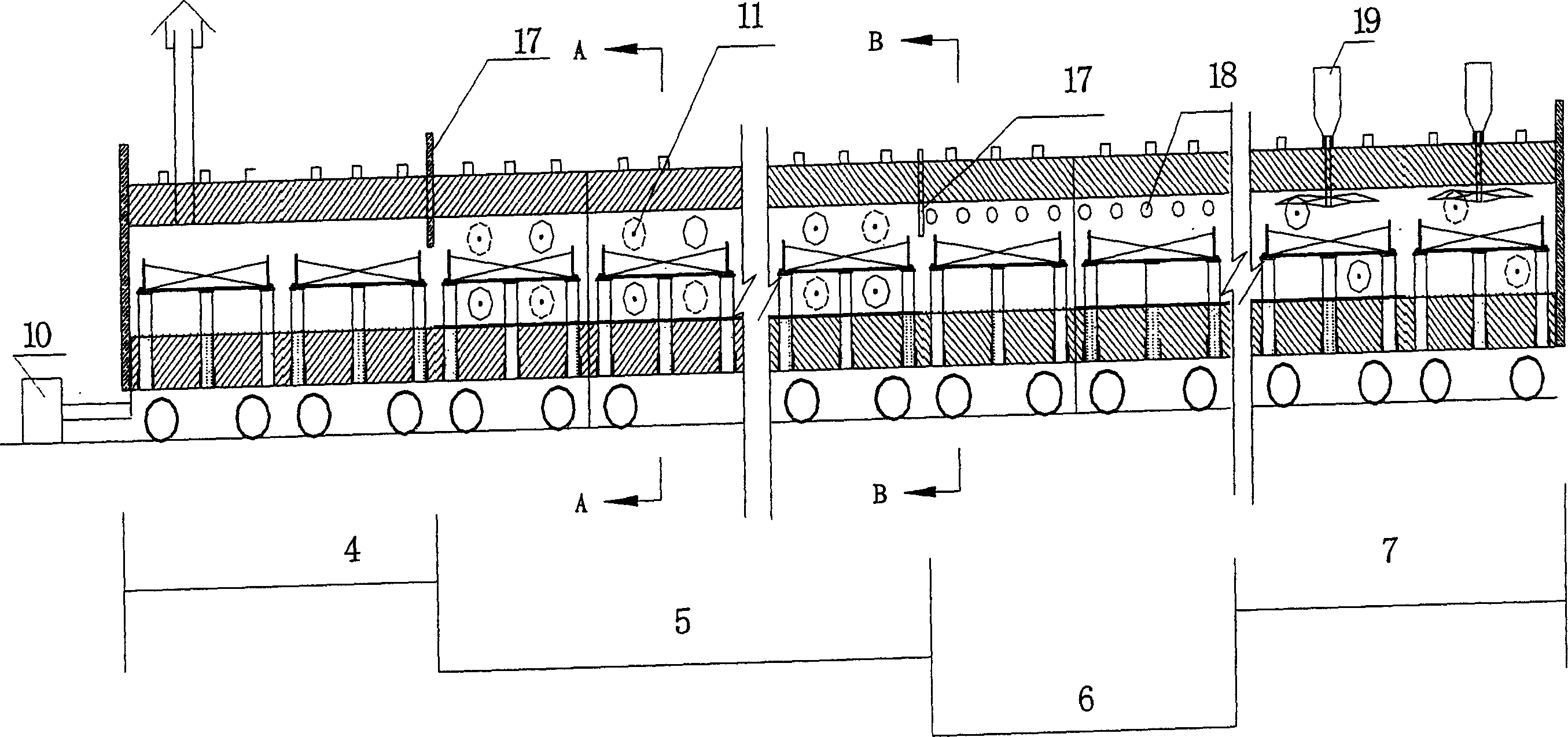

[0039] according to Figure 1-Figure 4 In the technical scheme and equipment diagram provided, the gas-fired tunnel kiln adopts a modular design, and the size of each module is 1 to 2 meters, which is convenient for transportation and installation, and can adapt to different process curves by adding or reducing modules.

[0040] Using a gas-fired tunnel kiln as a foam glass foaming kiln, the length of the production line can be at least 30 meters, and the inner width can be at least 1800mm. If the length of each kiln car 18 is set to 1000mm, the operating cycle of foam glass in the gas tunnel kiln is 2 ~3 hours, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com