Three-lead feeding mechanism of combined firework pot adhesion device

A technology combining fireworks and lead wires, applied in the direction of offensive equipment, pyrotechnics, weapon types, etc., can solve problems that are difficult to meet actual production and affect work efficiency, and achieve the effects of compact and small mechanism, smooth delivery and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

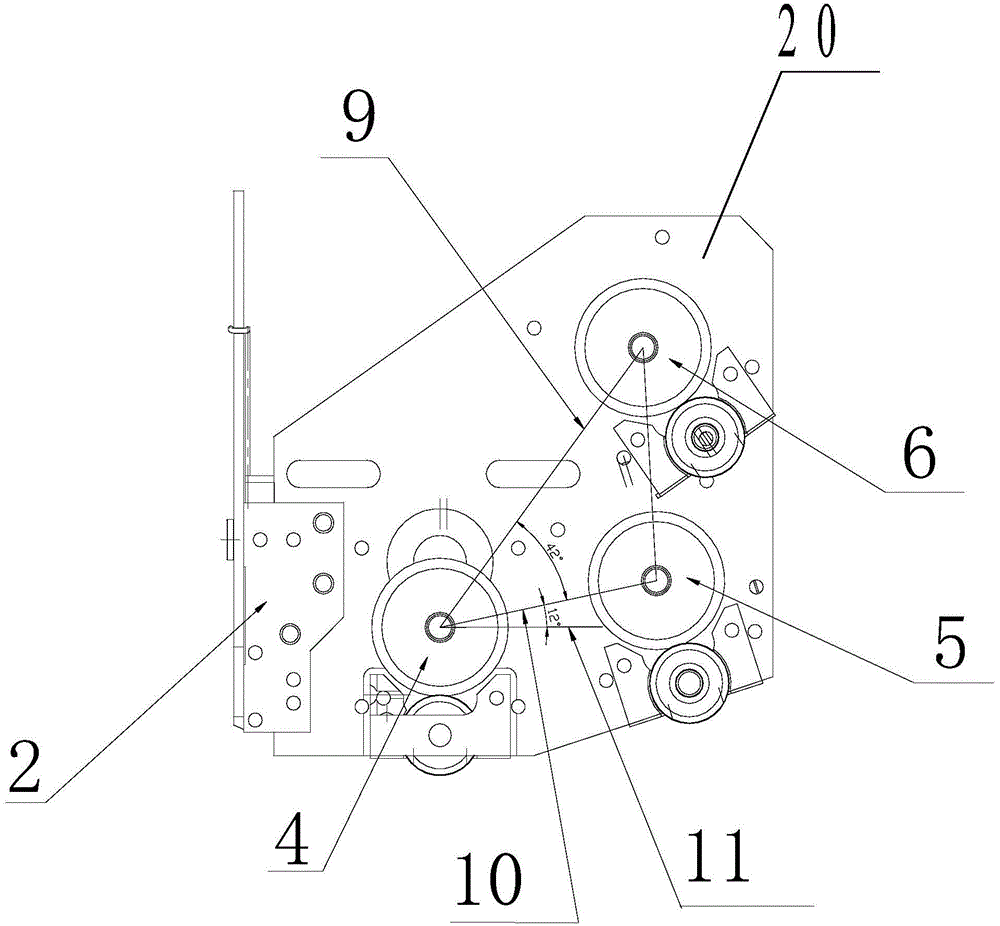

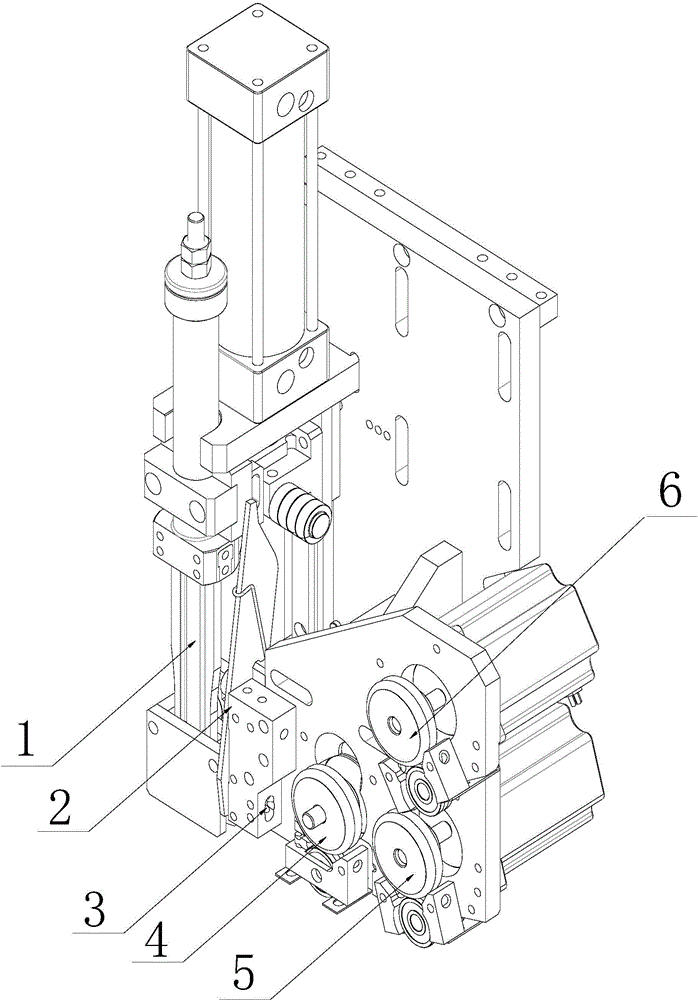

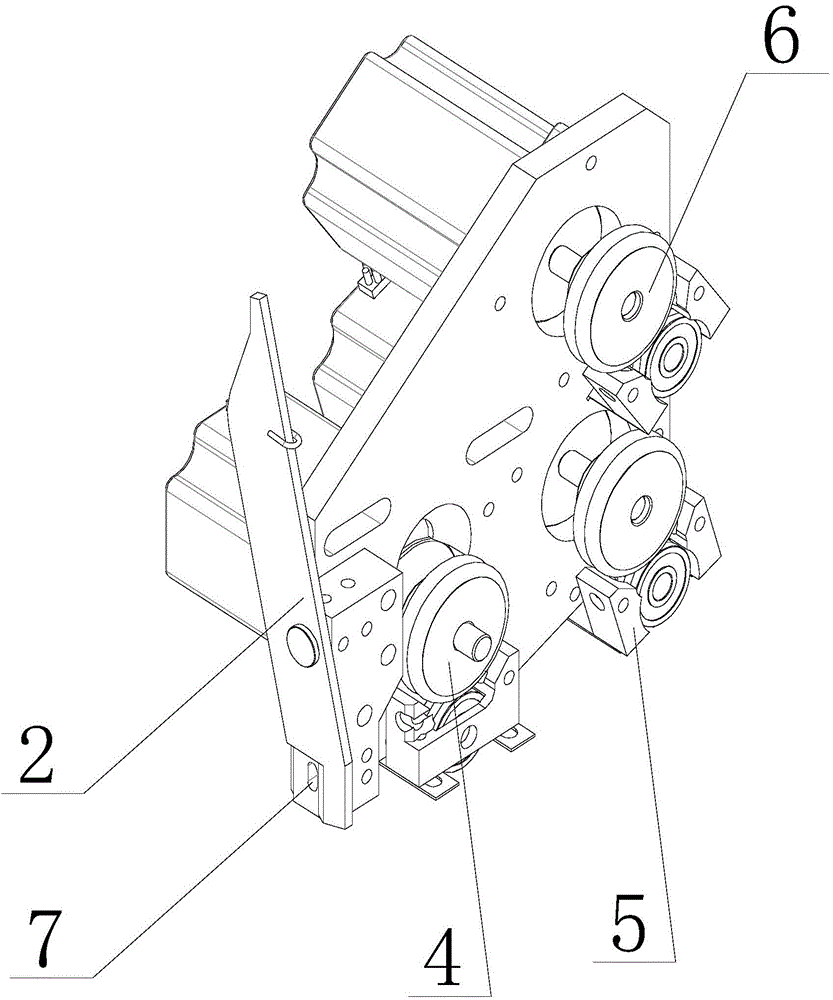

[0020] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the three-lead wire feeding mechanism of the combined fireworks potting device supplies the lead wires to the punching and inserting device 1 through the cutting and leading mechanism 2 .

[0021] The three-lead feeding mechanism includes a base plate 20, on the base plate 20, a first feeding unit 4 and a second feeding unit 5 are arranged on the base board 20, and each feeding unit is composed of a feeding wheel that clamps a lead wire up and down. The group and the lead wire conveying pipeline are formed, and the third lead-in unit 6 is also installed on the substrate, and the third lead-in unit 6 is located above the first lead-in unit 4 and the second lead-in unit 5, and the three lead-in units The center of the pulley is distributed in a triangle on the base plate 20;

[0022] The third delivery unit 6 is provided with a curved lead wire delivery pipeline 601; the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com