Arm type current collector

A collector and arm type technology, applied in the field of improvement of tension collectors, can solve problems such as large maintenance workload and achieve the effect of smooth distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

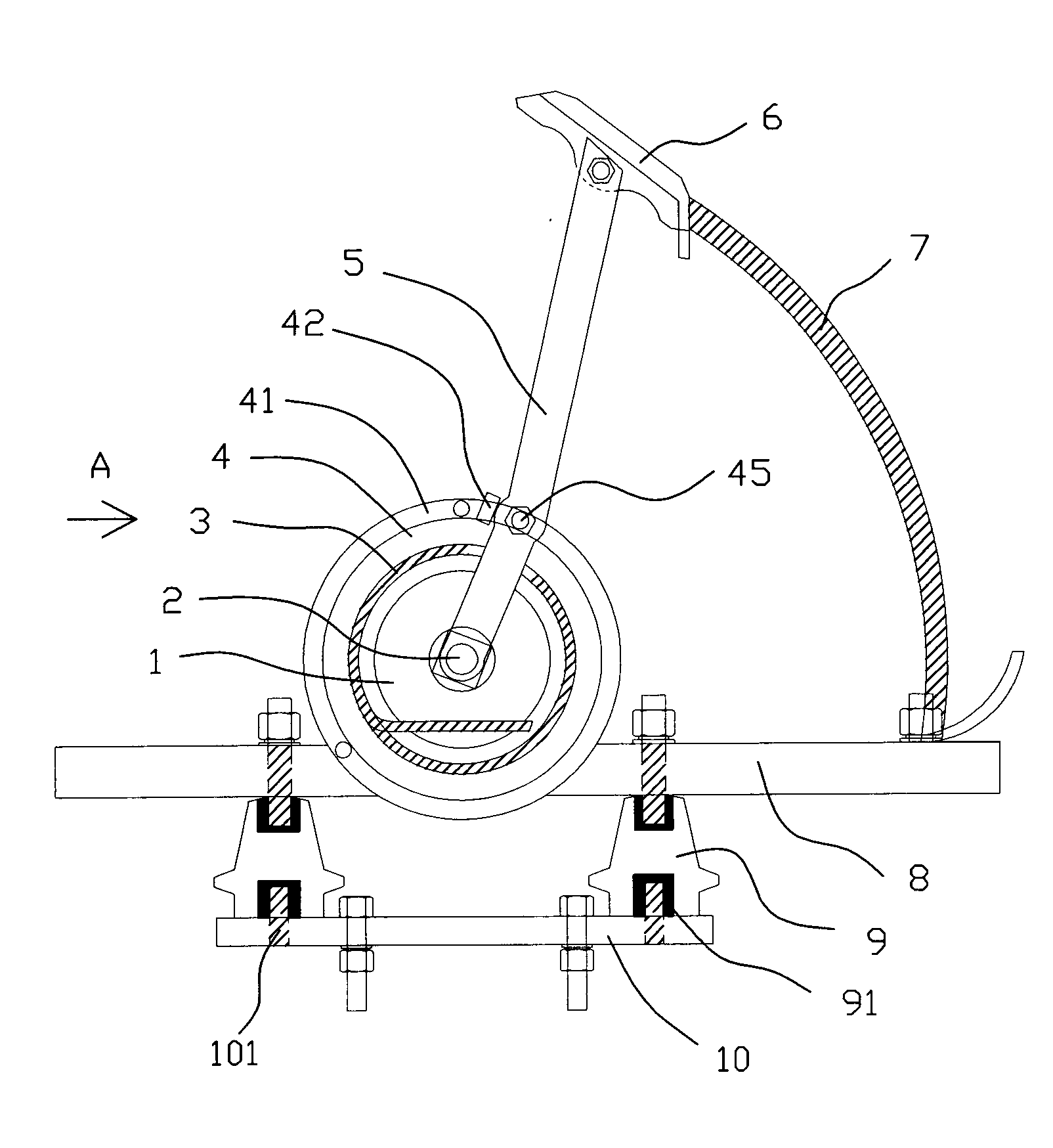

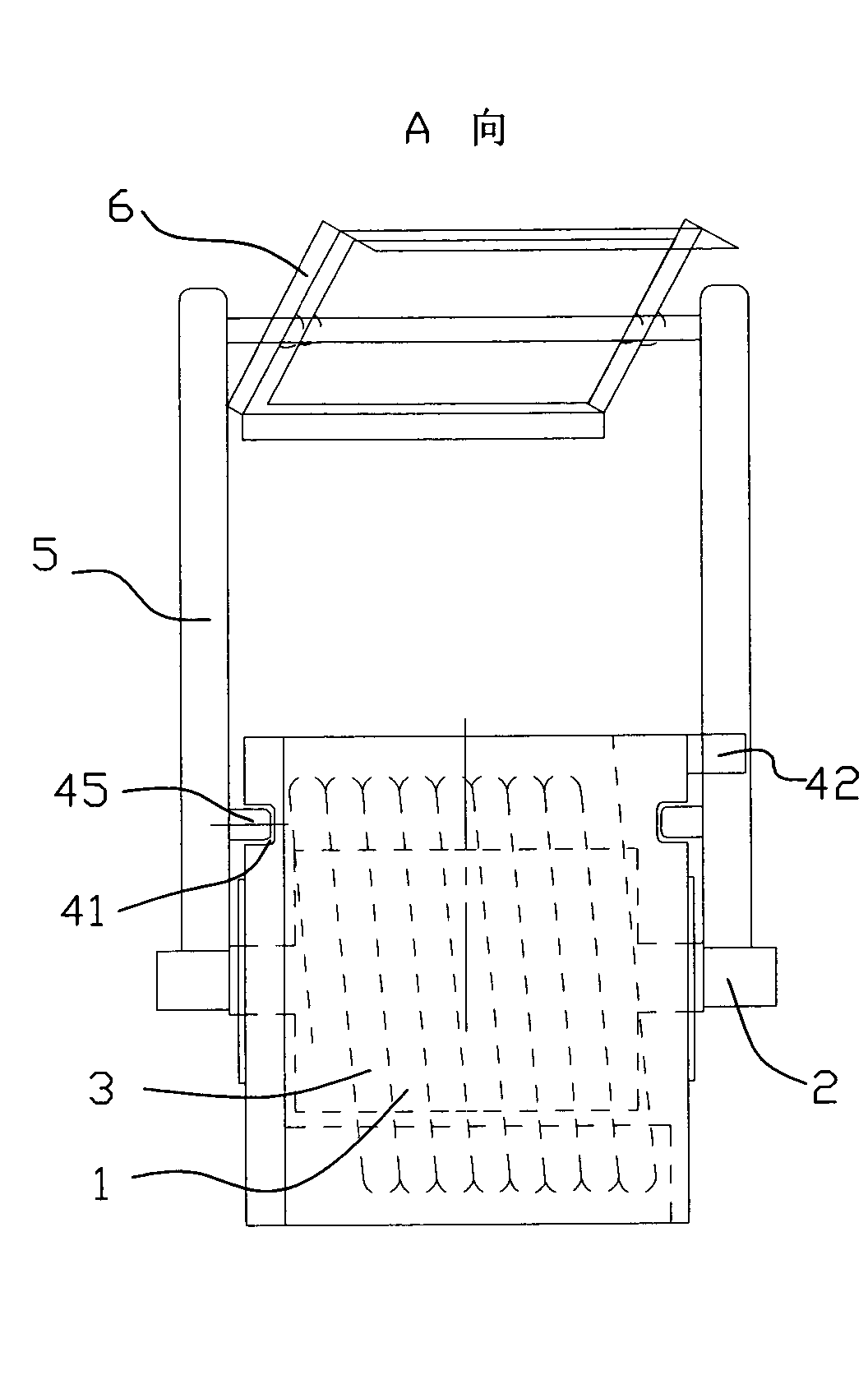

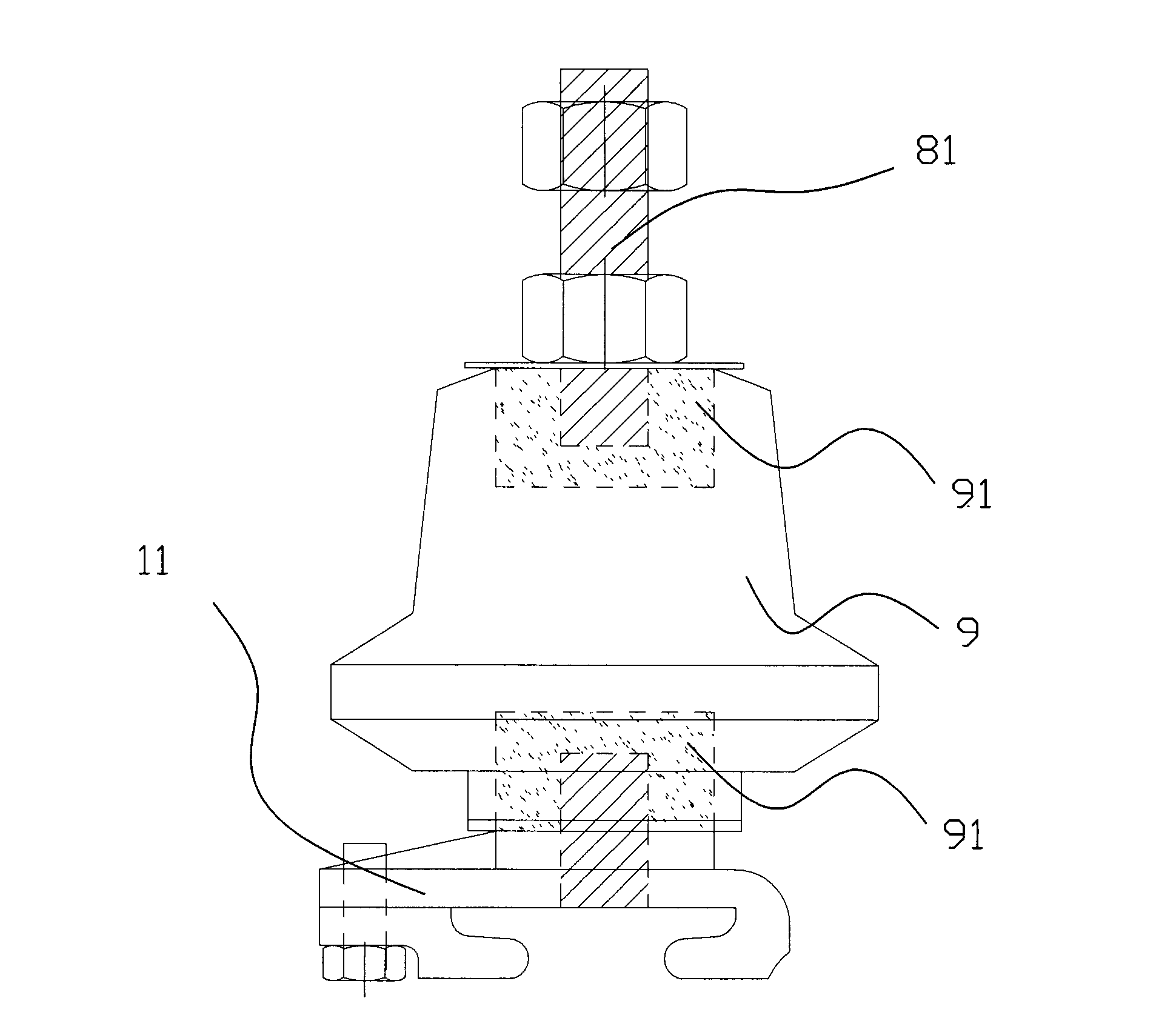

[0017] The present invention as Figure 1-3 As shown, it includes an outer cylinder 4, an inner cylinder 1, a torsion spring 3 arranged between the outer cylinder 4 and the inner cylinder 1, a rotating arm 5, a brush 6, a cable connection column, and a flexible cable connected to the cable connection column. Conductive strip 7, base plate 8 and seat plate 10, the brush 6 is movably connected to the head end of the rotating arm 5, the outer cylinder 4 is fixedly connected with the base plate 8 as a whole, the outer cylinder 4 The end face is provided with a circle of grooves 41 . When specifically making the connected outer cylinder 4 and base plate 8, the integral molding method is adopted, and a part of the outer cylinder 4 is "sinked" into the lower part of the base plate 8, which can further reduce the overall height, and is more convenient to bear the torsion spring 3 of elasticity.

[0018] The tail end of the rotating arm 5 is connected to the shaft head 2 of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com