Multistage segmental tower type simulation continuous crystallizer

A crystallizer and tower technology, applied in the field of multi-stage segmented tower simulating continuous crystallizers, can solve the problems of long cycle, low efficiency of batch crystallizers, difficulty in producing high-purity products, etc., and achieve supersaturation of mother liquor. Eliminate, improve operational efficiency and quality stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

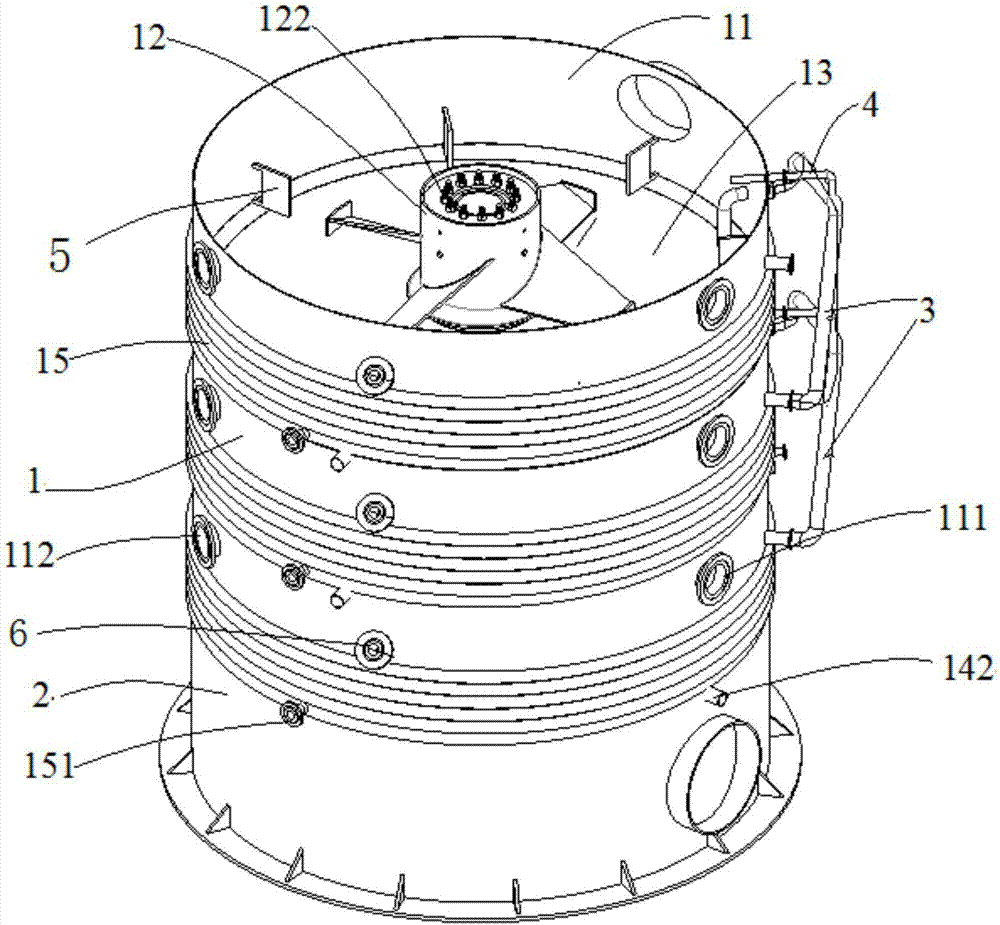

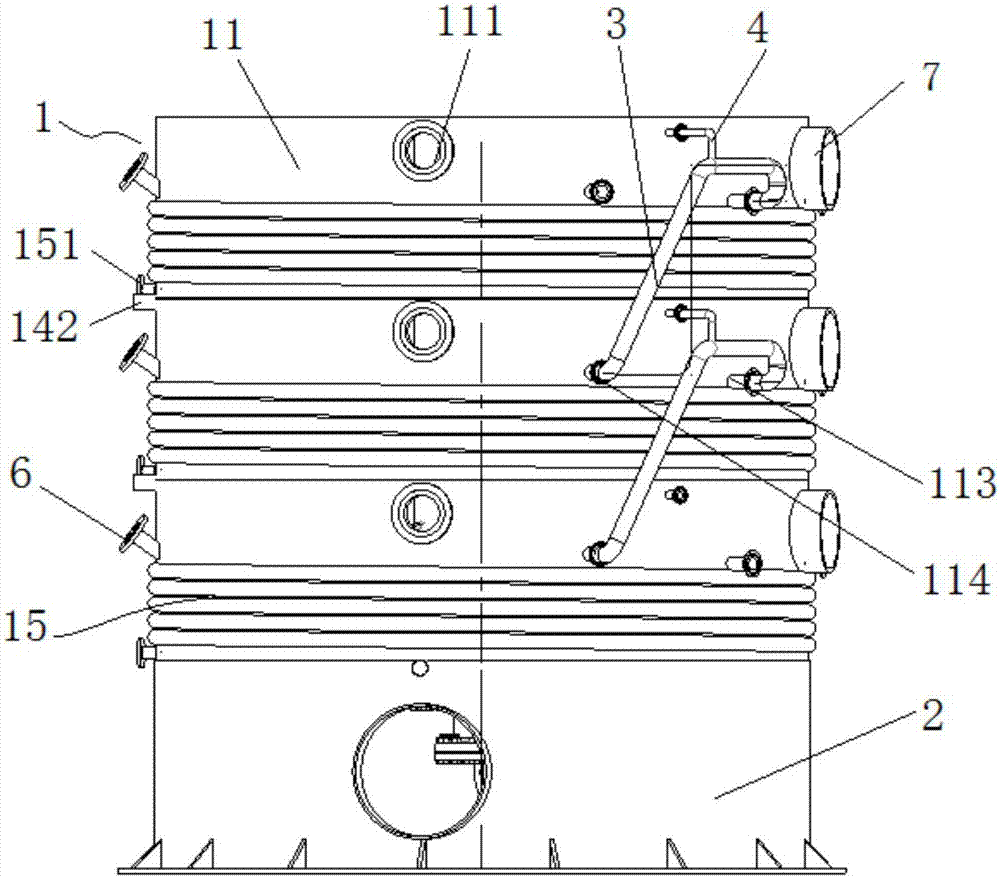

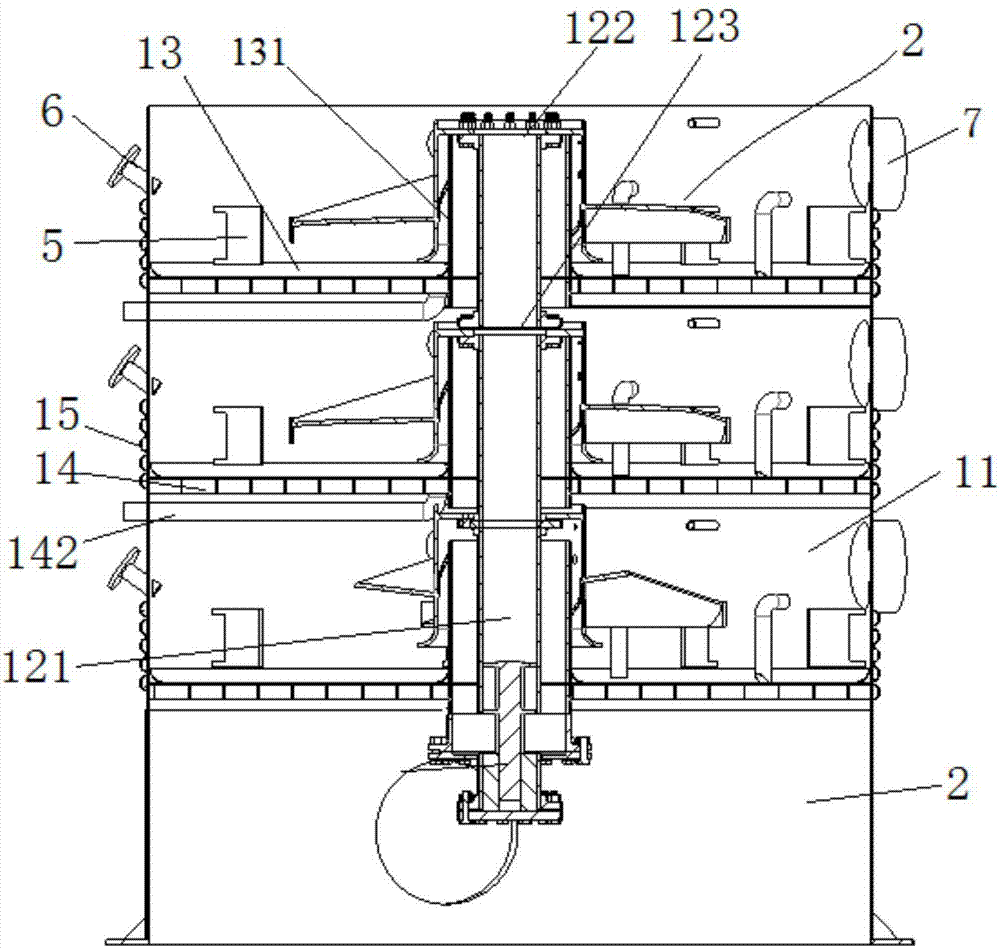

[0048] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a kind of multi-stage segmented tower simulation continuous crystallizer, and crystallizer comprises a plurality of crystallizer units 1 connected in series up and down step by step, and each stage of crystallizer unit 1 comprises cylinder 11 and is located in circle An agitator 12 with stirring blades in the inner cavity of the cylinder 11; a tray 13 sealingly connected to the inner edge of the cylinder 11 is provided in the cylinder 11, and the agitator 12 in the crystallizer unit 1 of each level runs through the tray vertically 13, the upper and lower ends of the stirrer 12 respectively form a detachable and fixed connection with the stirrer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com