Flattening conveying method suitable for flat rolling packing machine

A packaging machine and conveying direction technology, applied in the field of flat roll paper packaging technology, can solve problems such as reduced efficiency, inability to operate normally, production line failure, etc., to avoid misalignment, omit the turning process, and achieve smooth and tidy conveying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

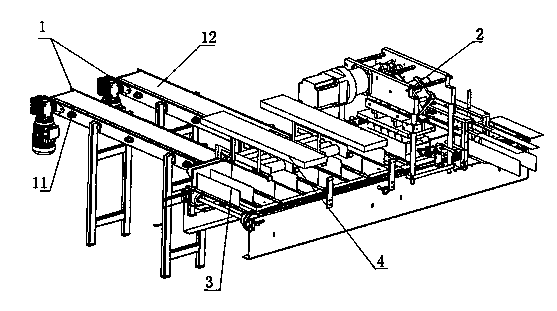

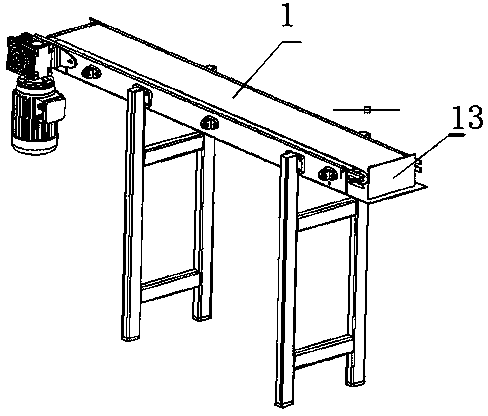

[0042] As a preferred embodiment of the present invention, this embodiment includes:

[0043] A flattening conveying method suitable for a flat roll packaging machine, the steps are as follows:

[0044] Material arranging step: it is used to arrange the conveyed materials in a row, and the number of rows in a row is preset; and the arranged materials are clamped and conveyed to

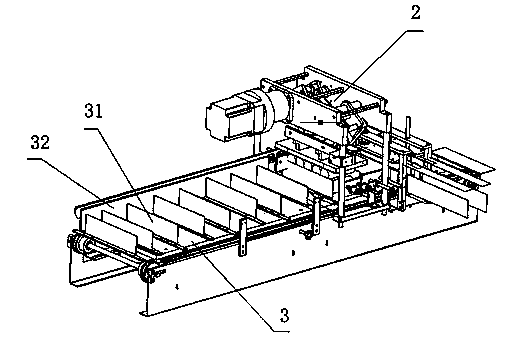

[0045] Material stacking step: it is used to clamp and convey a row of materials with the same number of stacked materials on top of the materials that have been arranged in a row to form two layers of materials; and convey the two layers of materials to

[0046] Material flattening step: It is used to flatten the stacked two-layer material; and transport the flattened material to the next station.

[0047] In the flattening conveying method of the present invention, the conveyed materials are first arranged in a row, and the materials arranged in a row are clamped and transported to the clamping con...

Embodiment 2

[0049] As another preferred embodiment of the present invention, this embodiment is a further supplement and description to Embodiment 1,

[0050] A flattening conveying method suitable for a flat roll packaging machine, the steps are as follows:

[0051] Material arranging step: it is used to arrange the conveyed materials in a row, and the number of rows in a row is preset; and the arranged materials are clamped and conveyed to

[0052] Material stacking step: it is used to clamp and convey a row of materials with the same number of stacked materials on top of the materials that have been arranged in a row to form two layers of materials; and convey the two layers of materials to

[0053] Material flattening step: It is used to flatten the stacked two-layer material; and transport the flattened material to the next station.

[0054] In the flattening conveying method of the present invention, the conveyed materials are first arranged in a row, and the materials arranged in ...

Embodiment 3

[0058] As another preferred embodiment of the present invention, this embodiment is a further improvement on the basis of Embodiment 2. Compared with Embodiment 2, this embodiment improves the conveying efficiency and packaging efficiency. This embodiment includes:

[0059] A flattening conveying method suitable for a flat roll packaging machine, the steps are as follows:

[0060] Material arranging step: it is used to arrange the conveyed materials in a row, and the number of rows in a row is preset; and the arranged materials are clamped and conveyed to

[0061] Material stacking step: it is used to clamp and convey a row of materials with the same number of stacked materials on top of the materials that have been arranged in a row to form two layers of materials; and convey the two layers of materials to

[0062] Material flattening step: It is used to flatten the stacked two-layer material; and transport the flattened material to the next station.

[0063] In the flatteni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com