Polyester spinning device for spinning

A spinning device, polyester technology, applied in textiles and papermaking, feeding solution to the spinneret, melt spinning, etc., can solve the problem of low efficiency of polyester filaments, achieve good promotion and utilization value, avoid mutual adhesion, deliver a smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

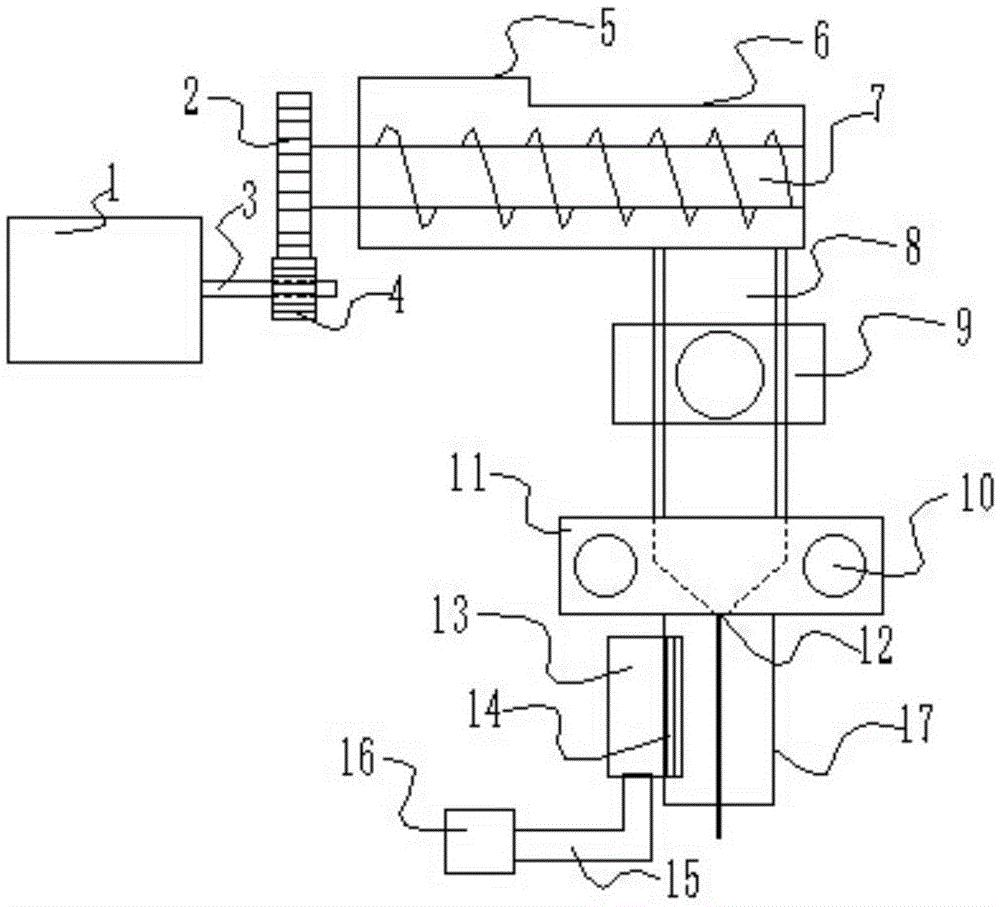

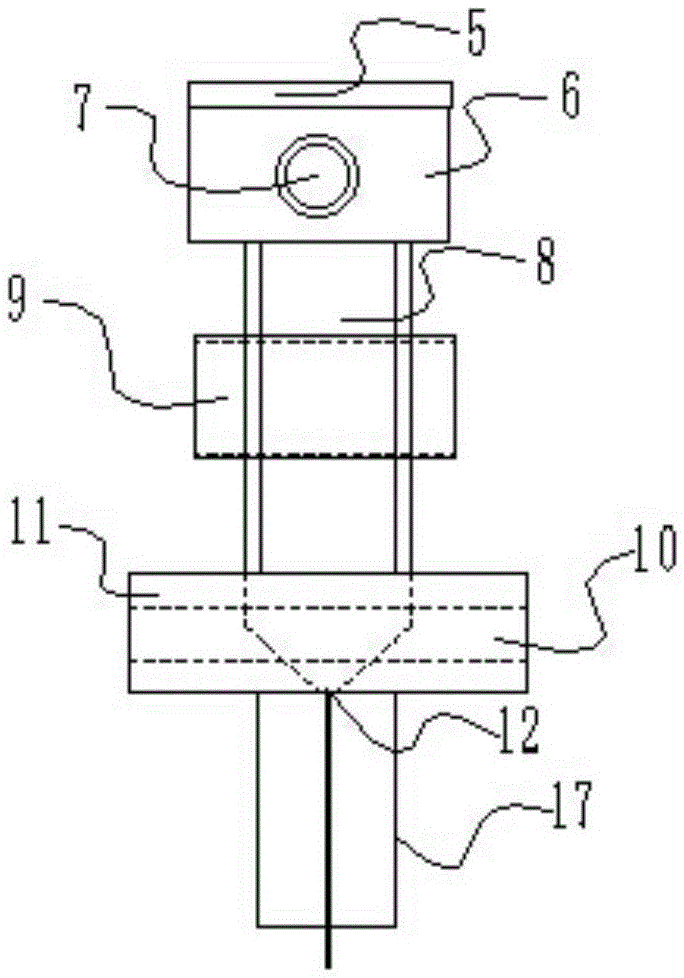

[0017] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

[0018] Such as figure 1 , figure 2 As shown, the structure of this kind of polyester spinning device for weaving includes a feed box 6, the upper end of the feed box 6 is provided with a feed port 5, and the inside of the feed box 6 is horizontally provided with a feed screw 7 , one end of the feed screw 7 stretches out of the feed box and is provided with a first gear 2 at the end, the first gear 2 meshes with the second gear 4, and the second gear 4 is connected with the motor 1 through the transmission rod 3, so , the motor 1 can drive the second gear 4 to rotate, the feed screw 7 can ensure that the polyester raw pulp enters the feed pipe 8 evenly, and the meshing between the gears makes the transmission more stable.

[0019] In the above example, specifically, the lower end of the feed box 6 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com