Automatic conveying device for Kandelia candel

A technology of automatic conveying device and candela, which is applied in the direction of conveyor control device, conveyor, conveyor objects, etc., and can solve the problems of high manual operation intensity, breaking and destroying candela

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

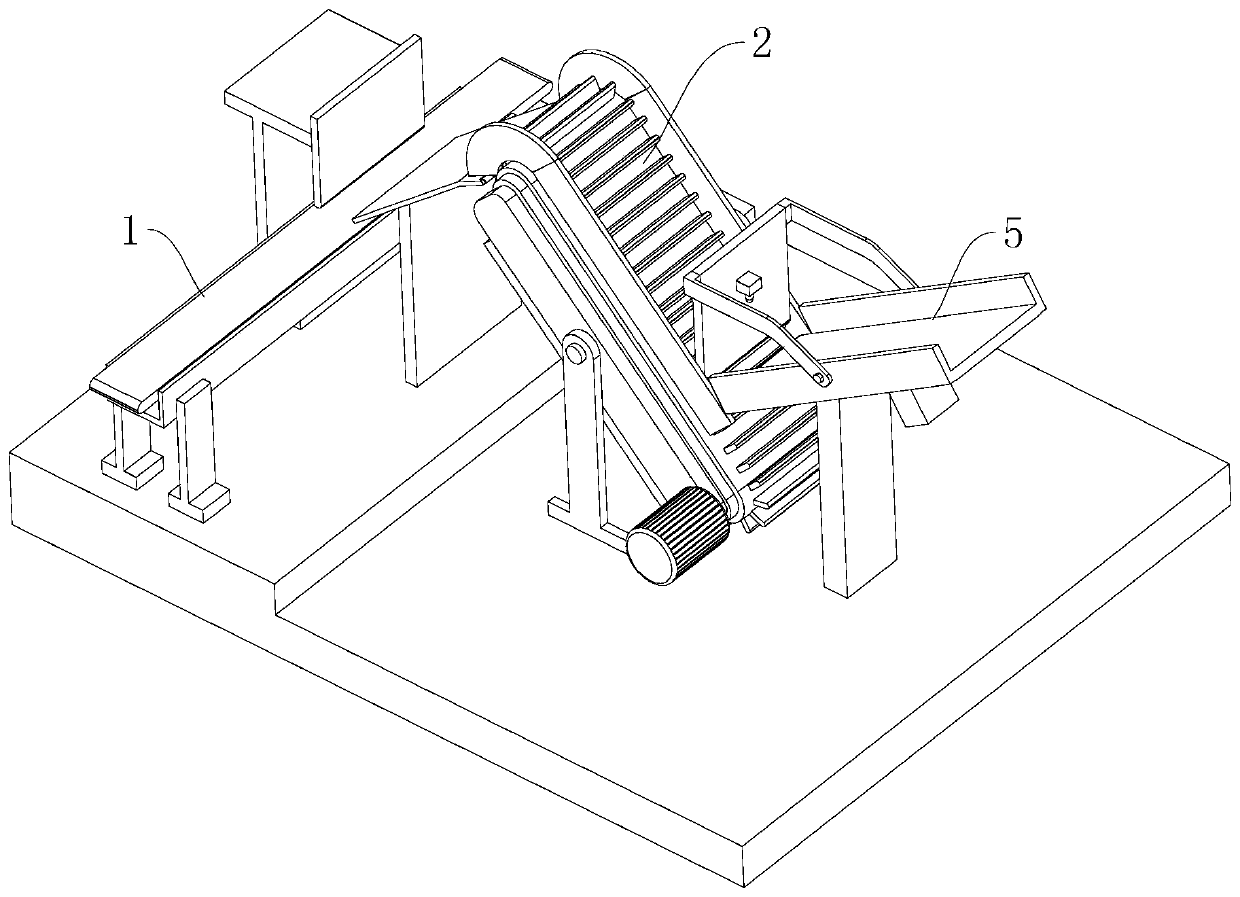

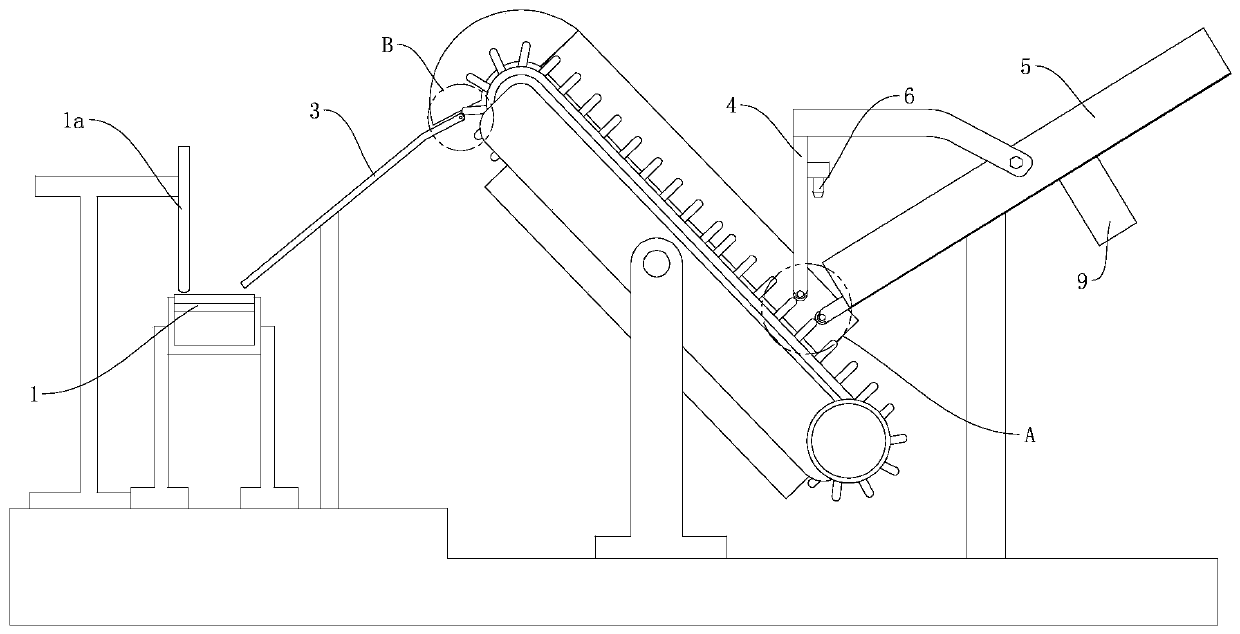

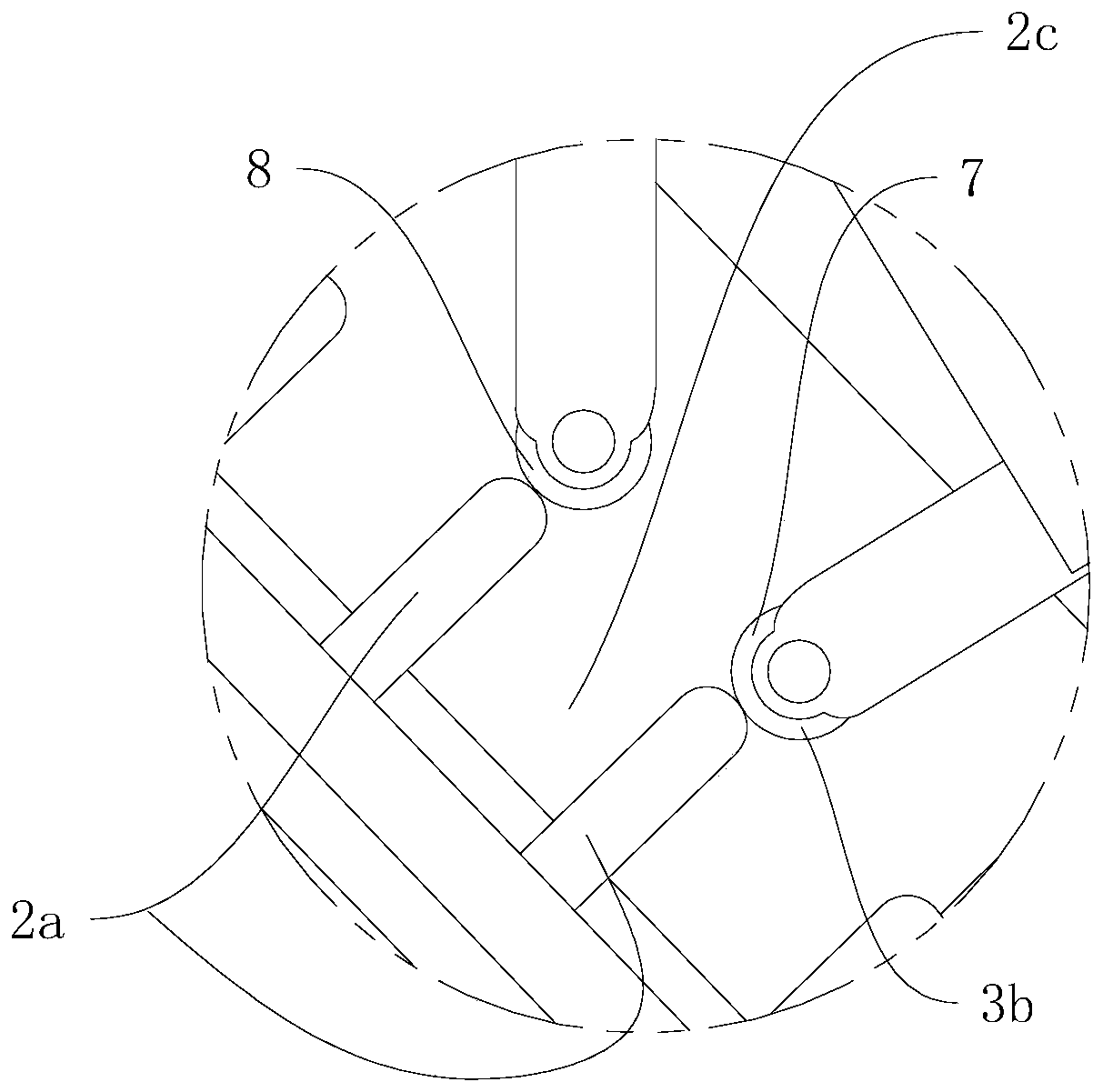

[0031] refer to Figure 1 to Figure 6 The shown automatic candela conveying device includes a discharge conveyor belt 1, and also includes a transport conveyor belt 2, a material guide plate 3, a controller, a blanking slideway 5, a distance measuring sensor 6, a first drainage mechanism and a second drainage mechanism, The conveying conveyor belt 2 is arranged obliquely, and its downstream end faces upwards, and the blanking chute 5 is arranged on one side of the conveying conveying belt 2 in an inclined posture, and a gap is formed between the downstream end of the blanking chute 5 and the upstream end of the conveying conveying belt 2. The opening faces upward at an obtuse angle of 135°, and the first drainage mechanism and the distance measuring sensor 6 are arranged between the two, the distance measurement sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com