Standard motor train unit power bogie frame

A technology for power bogies and EMUs, applied in bogies, railway car body parts, transportation and packaging, etc., can solve the problems of weak anti-fatigue performance, unfavorable welding seam fatigue performance, and inability to transmit stress evenly, to meet international requirements. Advanced standards, to meet safe and reliable operation, to achieve the effect of smooth transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

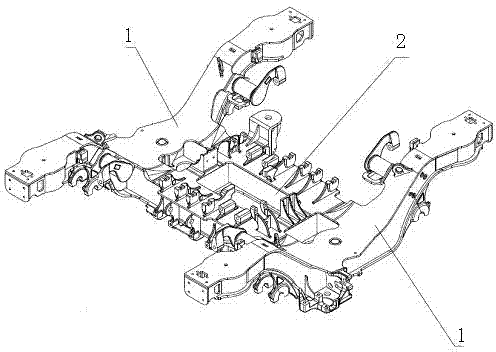

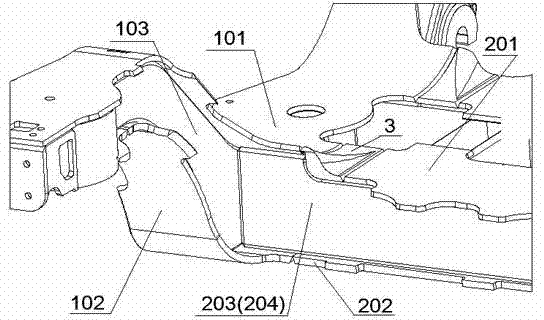

[0015] refer to figure 1 , figure 2 , the main body is composed of two side beams 1 and a beam 2, the main body of the side beams and the beams adopts a box-type welding structure, and is connected in a plug-in manner. The plate 101 is extended inwardly to realize variable cross-section docking through the connecting block 3 and the upper cover plate 201 of the beam. The connecting block 3 is a space curved surface structure. The plate 203 and the inner vertical plate 204 respectively extend outward and insert into the side beam 1 and directly connect with the inner vertical plate 103 of the side beam.

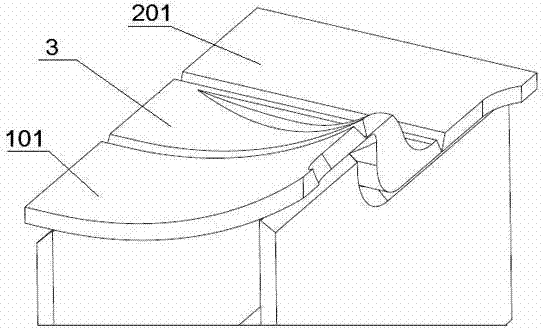

[0016] refer to image 3 , for the variable cross-section connection between the beam top cover plate 201 and the side beam top cover plate 101, the equal-strength connection is satisfied, that is, the cross-section change does not cause stress concentration and the stress level is equivalent. In order to achieve better connection functions on both sides, the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com