Urban sewage treatment aerating device

An aeration device and urban sewage technology, which is applied in the field of environmental pollution control, can solve problems such as bad smell, consume a lot of energy, and complex components, and achieve the effects of avoiding transmission failure, increasing contact area, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

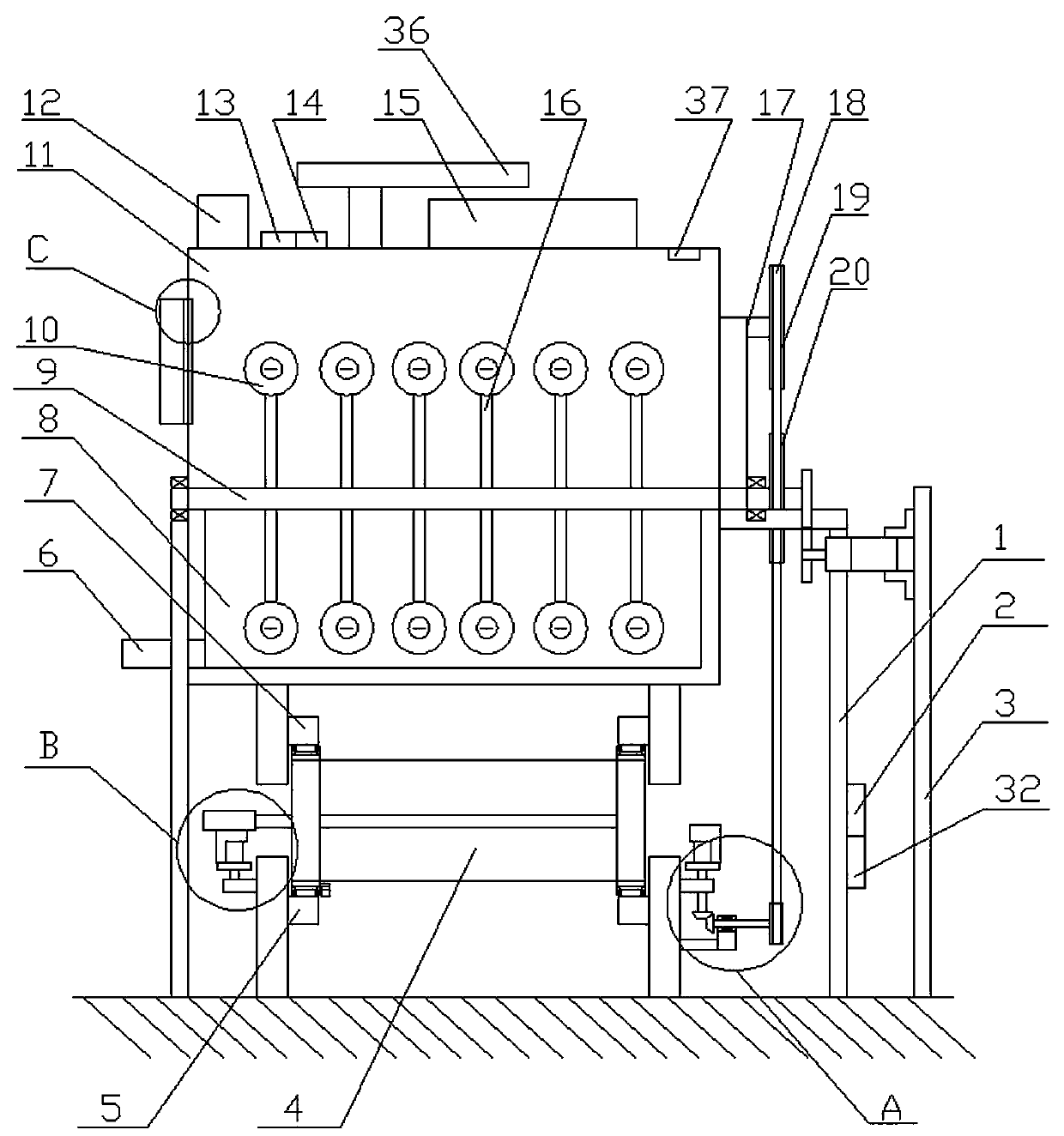

[0049] Embodiment 1, an aeration device for urban sewage treatment, including a three-dimensional aeration tank 8 arranged on a plurality of support columns 1, a stirring mechanism arranged on the three-dimensional aeration tank 8, and a stirring mechanism arranged on a plurality of the support columns 1 The lower part of the column 1 is used for the wind driving mechanism that matches the stirring mechanism, and is arranged on the side of the three-dimensional aeration tank 8 for connecting the stirring mechanism and the power transmission mechanism of the wind driving mechanism. An auxiliary drive mechanism matched with the power drive mechanism on one side of the support column 1, and a control mechanism for controlling the wind drive mechanism, the stirring mechanism, the power transmission mechanism, and the auxiliary drive mechanism;

[0050] The stirring mechanism includes a first bracket arranged at both ends of the three-dimensional aeration tank 8, a second bearing ar...

Embodiment 2

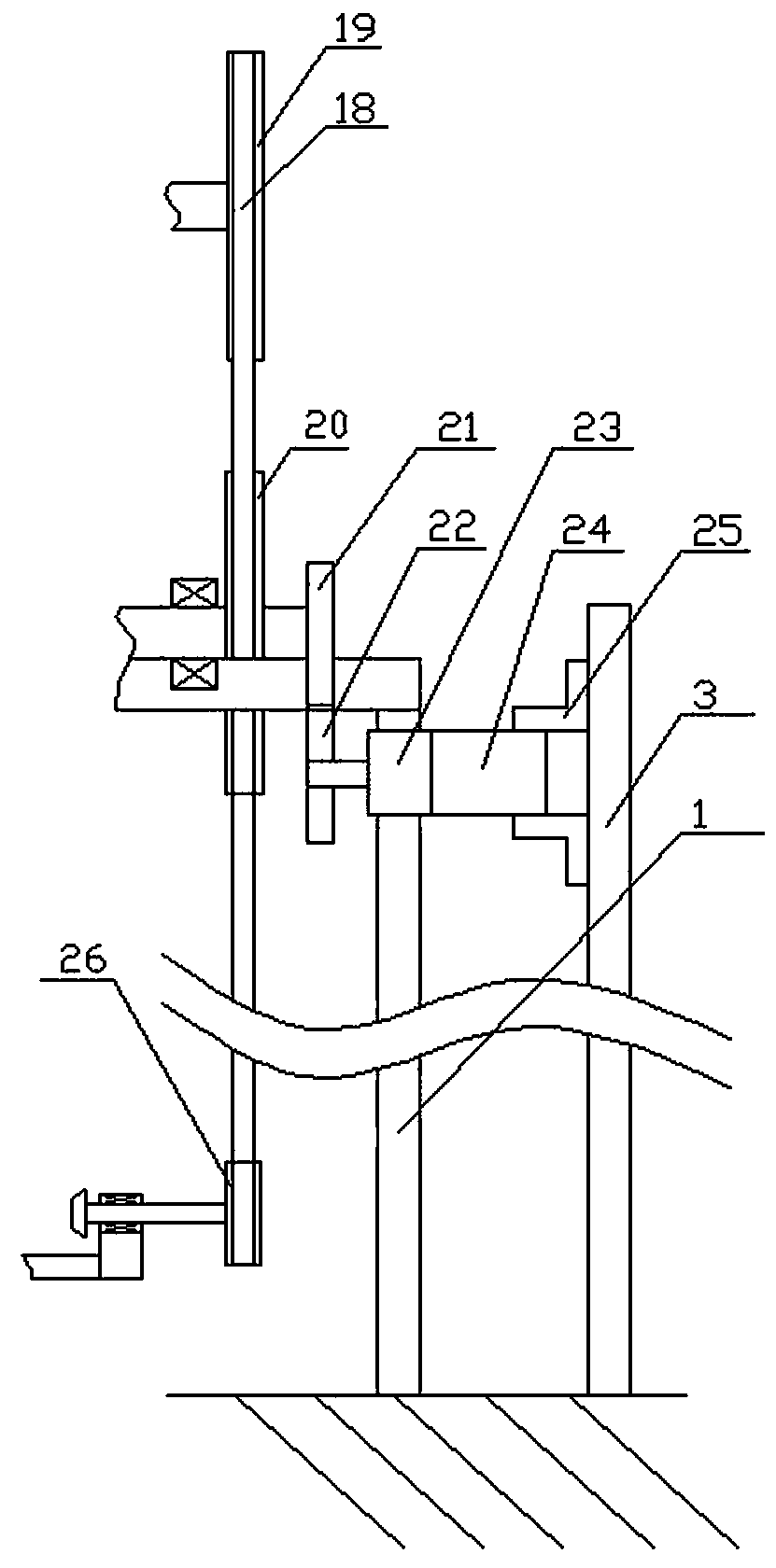

[0063] The difference from Embodiment 1 is that the power conversion unit includes a worm 34 arranged at the end of the transmission rod at the lower end of the driving wheel 29, a worm wheel 35 matched with the worm, and a worm wheel 35 matched with the worm wheel 35 for The worm gear shaft for power transmission is arranged at the end of the worm gear shaft and the first driving disc 26 that cooperates with the power transmission mechanism.

[0064] The three-dimensional aeration tank 8 is provided with a sealed upper cover 11, an air exchange hole arranged on the sealed upper cover 11, an air filter 15 arranged on the air exchange hole, and an air filter 15 arranged on the sealed upper cover 11. The feed port 12 is arranged at the discharge port 6 on the bottom surface of the three-dimensional aeration tank 8 .

[0065] The three-dimensional aeration tank used in this embodiment is provided with a sealed upper cover, which can form a closed fermentation space. In order to i...

Embodiment 3

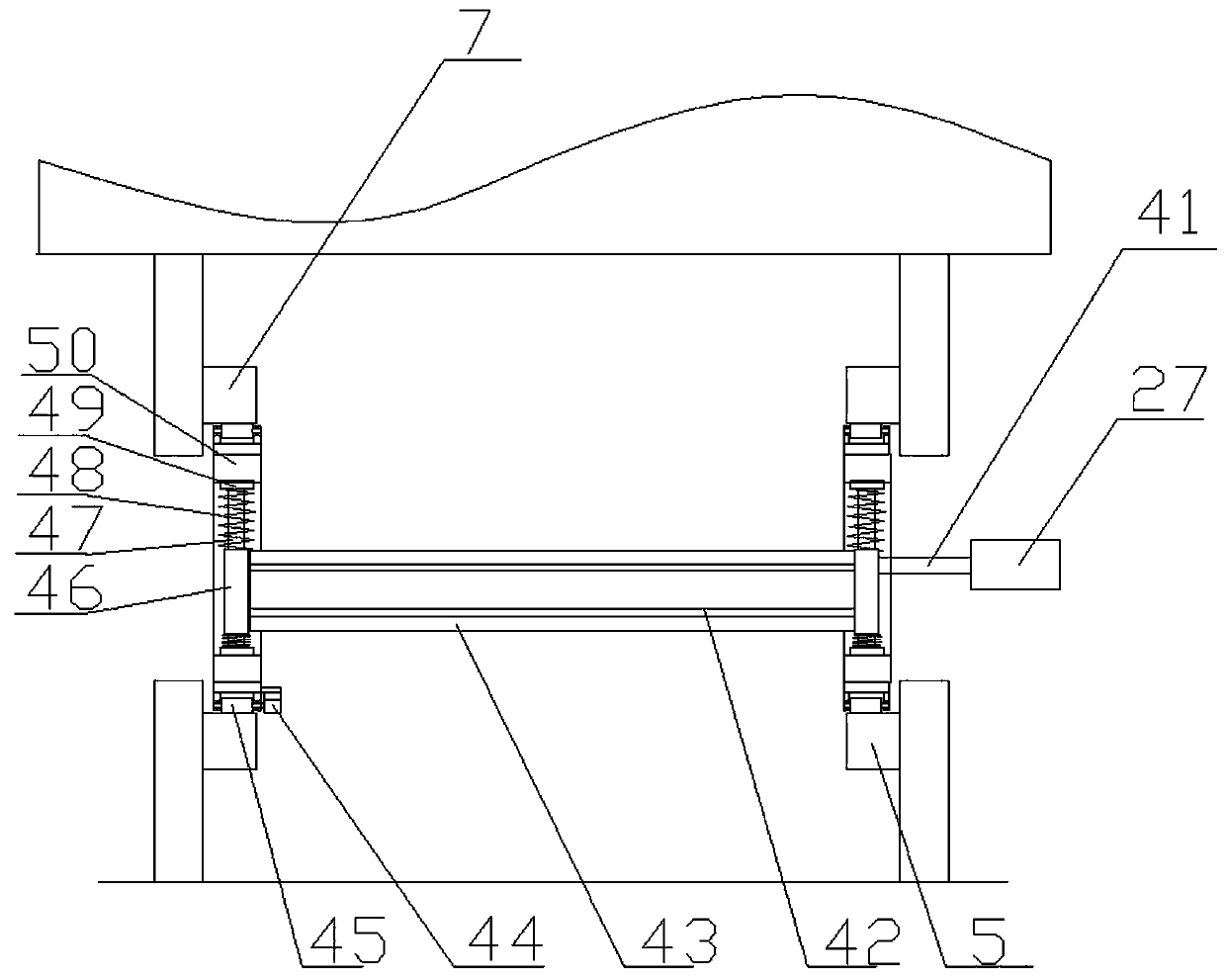

[0067] It differs from Embodiment 1 in that: the stirring unit 10 includes a bowl-shaped shell 101 arranged on the stirring rod 16, a round hole arranged at the top of the bowl-shaped shell 101, and an elastic rubber arranged in the round hole The membrane 102 is provided with a plurality of small holes 103 on the elastic rubber membrane 102 .

[0068] The core of the stirring unit adopted in this embodiment is a bowl-shaped shell, a round hole is set on it, and an elastic rubber film is set on the round hole, and in order to make the gas therein get rid of, a plurality of small holes are set on the elastic rubber film. The hole can be used during the stirring process, with the rotation of the stirring rod, so that as the pressure increases, the gas in it breaks through the shackles of the elastic membrane at the small hole to form continuous small bubbles to increase the contact area between the solution and the air , to ensure the effect of aeration; of course, a simple bowl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com