Method for controlling engine torque in hybrid-powered motor speed variator shift process

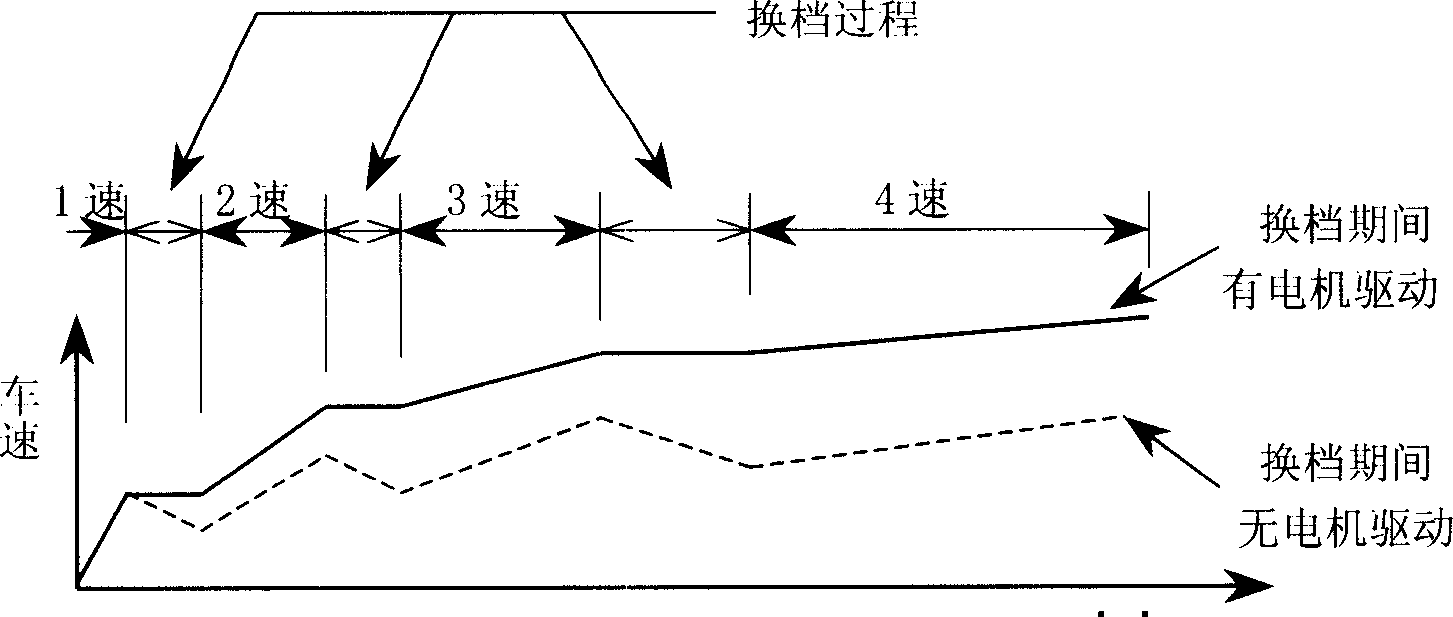

A hybrid vehicle, engine torque technology, applied in the direction of engine control, machine/engine, transmission control, etc., can solve problems such as insufficient smooth speed change, unsustainable transmission of internal combustion engine power, and uncomfortable occupants in the vehicle, and achieve smoothness. The effect of transmission, excellent shifting stability, and excellent vehicle riding comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

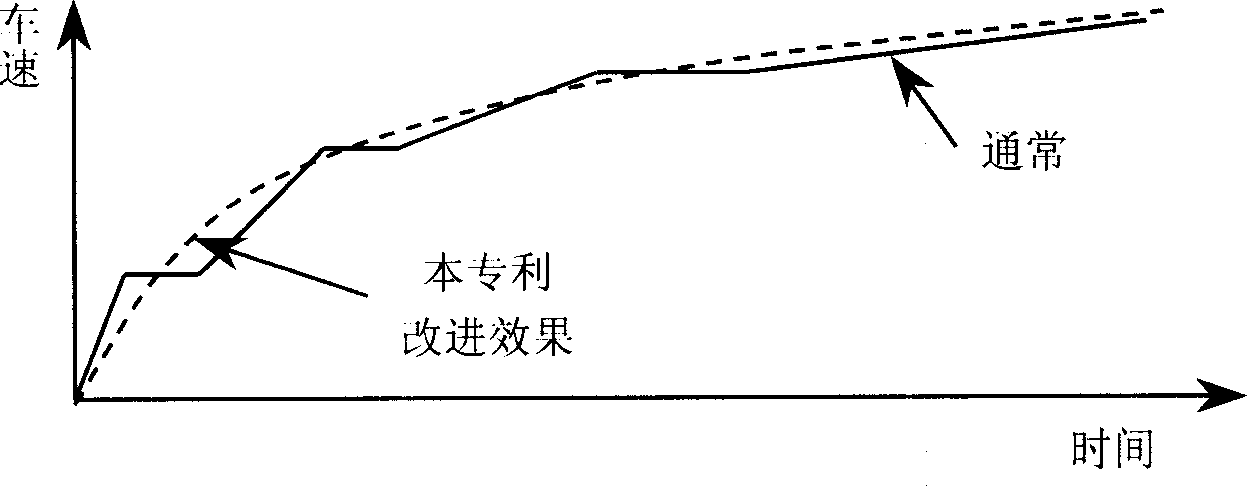

[0016] The output torque of the engine is used to compensate the change of the transmission output shaft torque caused by the change of the gear ratio after shifting, so that the engine torque on the output shaft of the transmission is the same before and after the shift, such as image 3 Shown (taking the transmission upshift as an example). This patent uses a controller as a carrier and is realized through a control system including the controller.

[0017] According to the vehicle speed and the position of the accelerator pedal, the controller calculates the torque T that the engine must exert on the output shaft of the transmission according to a determined method E2 .

[0018] Set the engine output torque T before shifting EB , transmission ratio G B ;Engine output torque T after gear shift EA , transmission ratio G A .

[0019] Then T EB =T E2 / G B ①

[0020] T EA =T E2 / G A =T EB ×G B / G A ②

[0021] The controller calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com