Plastic microinjection structure additionally with longitudinal-torsional ultrasonic vibration

An ultrasonic vibration and micro-injection technology, applied in the field of tight manufacturing, can solve problems such as low efficiency and poor injection accuracy, and achieve the effects of reducing energy consumption, avoiding pores and warping, and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

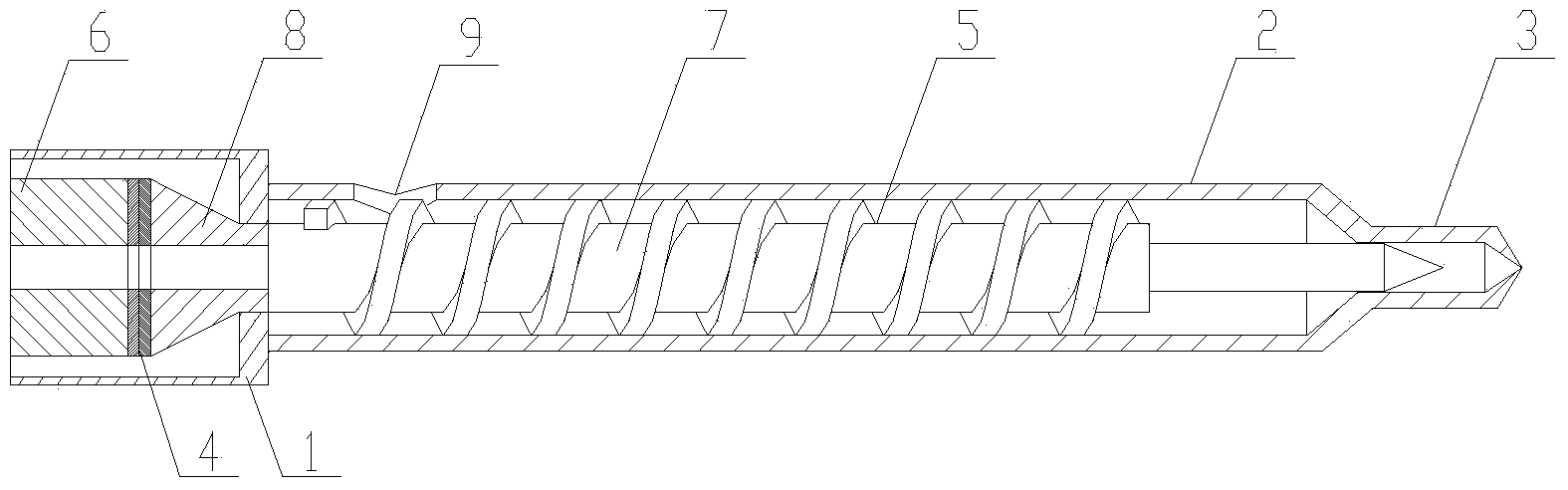

[0013] Please refer to the attached figure 1 , the embodiment of the present invention includes:

[0014] A plastic microinjection structure with longitudinal torsional ultrasonic vibration, such as figure 1 , which includes an injection sleeve 2 and a housing 1; the end of the injection sleeve 2 is an injection nozzle 3; the side wall of the injection sleeve 2 is also provided with a feed port 9 for filling raw materials. The injection sleeve 2 is connected with the shell 1. An injection screw 5 is arranged in the inner cavity of the injection sleeve 2. The surface of the injection screw 5 is processed with an asymmetrical spiral groove 7. One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com