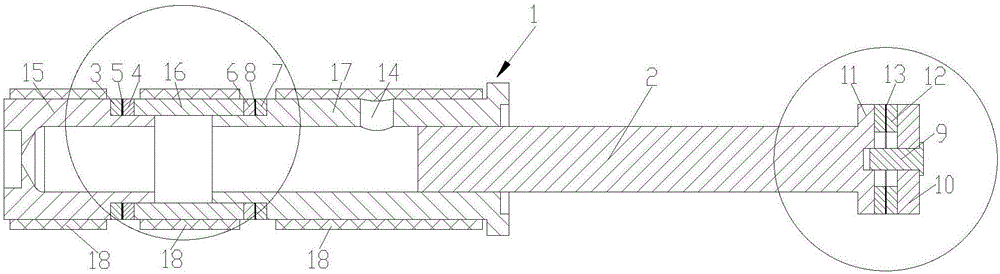

Plunger type precise injection device

An injection device, plunger-type technology, applied in the field of plunger-type precision injection devices, can solve problems such as difficulties, uneven plasticization, high melt viscosity, etc., to improve injection accuracy and efficiency, avoid air holes and warping, high The effect of promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

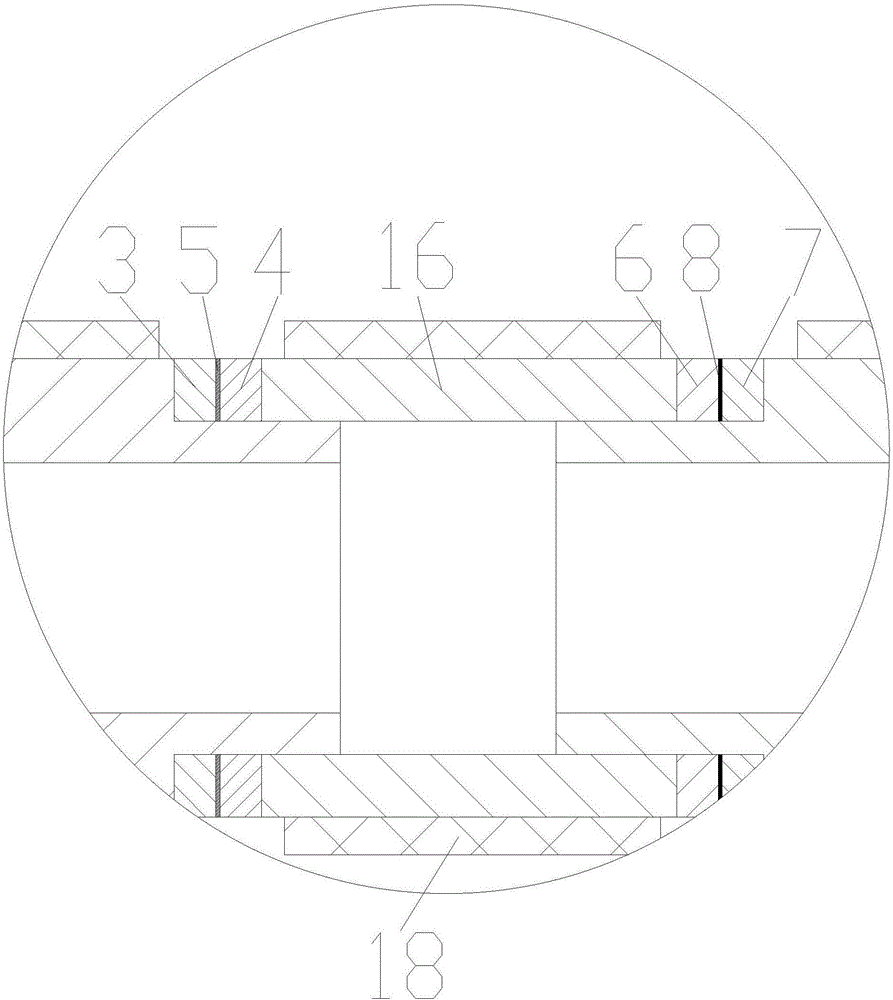

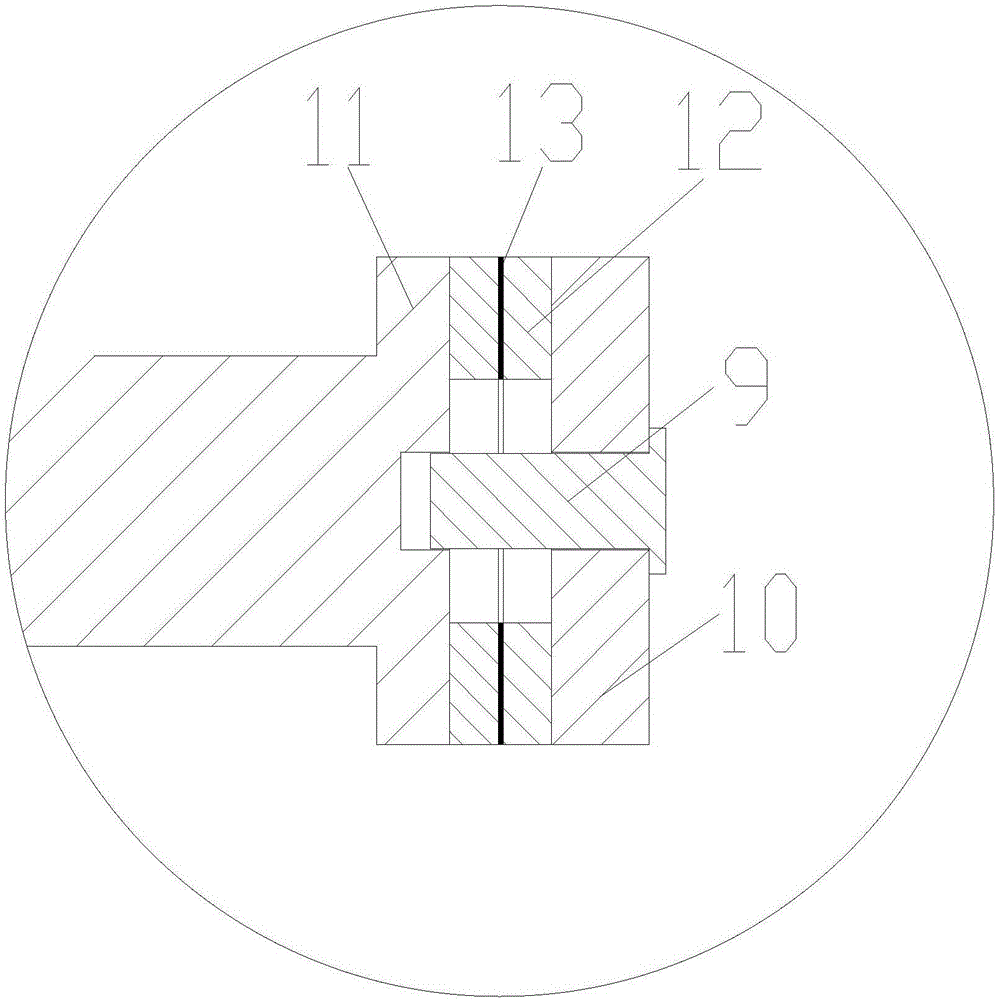

Examples

Embodiment 1

[0020] The polarization direction and superposition mode of the first piezoelectric ceramic and the second piezoelectric ceramic are as attached Figure 4 As shown in , the polarization directions of the two adjacent piezoelectric regions on the first piezoelectric ceramic sheet and the second piezoelectric ceramic are opposite, respectively denoted by "+" and "-". The first electrode is placed on the first piezoelectric ceramic Between the first piezoelectric ceramic and the second piezoelectric ceramic, an alternating voltage signal is applied to the first electrode, and the first piezoelectric ceramic and the second piezoelectric ceramic undergo bending deformation, which excites the bending vibration of the barrel; the third piezoelectric ceramic and the second piezoelectric ceramic The polarization directions and superposition methods of the four piezoelectric ceramics are shown in the attached Figure 5 As shown, the second electrode is placed between the third piezoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com