Intelligent vacuum glue filling machine

A glue filling machine and vacuum technology, applied in the field of glue filling machine, can solve the problems of difficult to eliminate air bubbles, high glue viscosity, and reduced insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

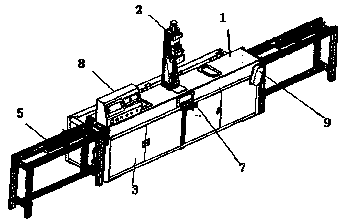

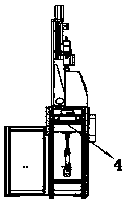

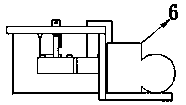

[0015] An intelligent vacuum glue filling machine, including a base 3, a vacuum cavity 1 is installed on the base 3, a glue filling machine 2, a monitoring screen 8, and an observation window 7 are installed on the vacuum cavity 1, and the glue filling machine 2 for injecting glue The glue injection port is installed inside the vacuum chamber 1 for monitoring the process of product glue injection and the time required for the product to be intact. The monitoring screen 8 is installed on the left side of the glue filling machine 2 for observing the glue filling machine in vacuum The observation window 7 for the glue injection process and the details of the glue injection process in the chamber 1 is installed on the side wall of the vacuum chamber 1, and the vacuum pump 6 for exhaust is arranged outside the vacuum chamber 1, and the vacuum pump passes through the pipeline and the vacuum chamber. The two ends of the vacuum chamber 1 are provided with a sealing door 4 for maintaini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com