Automatic fed livestock and poultry injection device

An automatic injection and poultry technology, applied in the field of poultry and livestock breeding, can solve the problems of inconvenient weighing and injecting drugs, and achieve the effects of saving manpower and time costs, improving injection efficiency, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

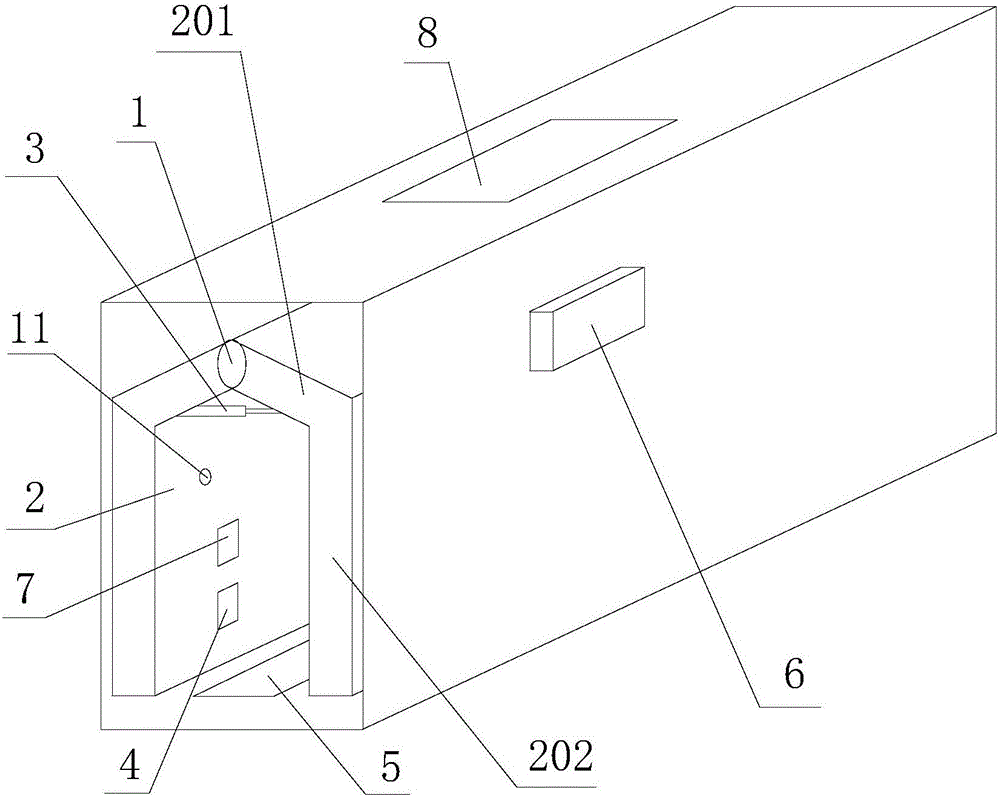

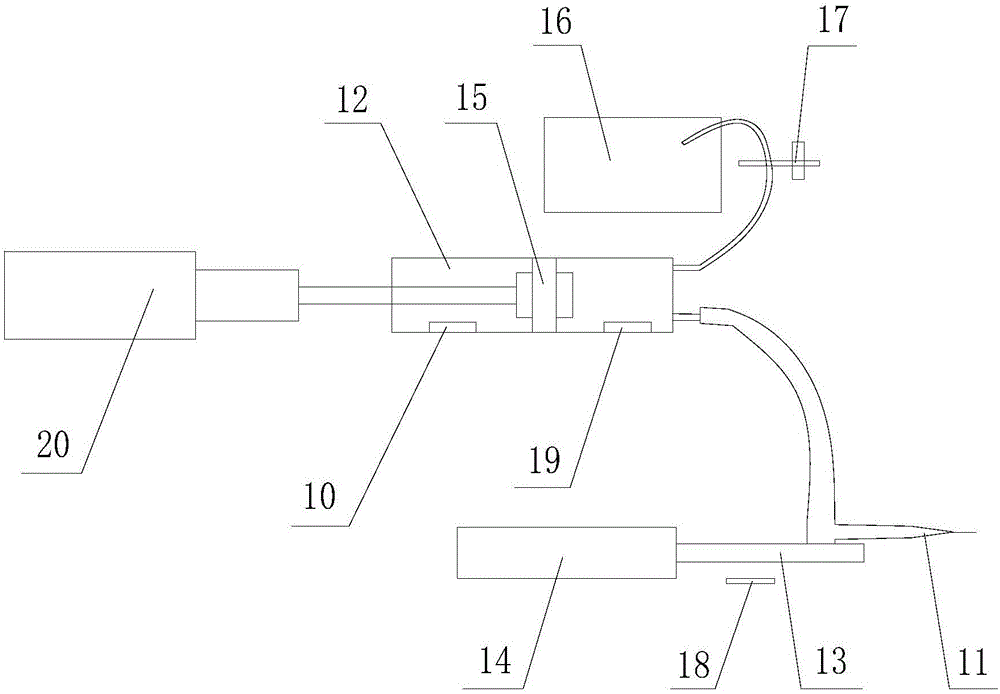

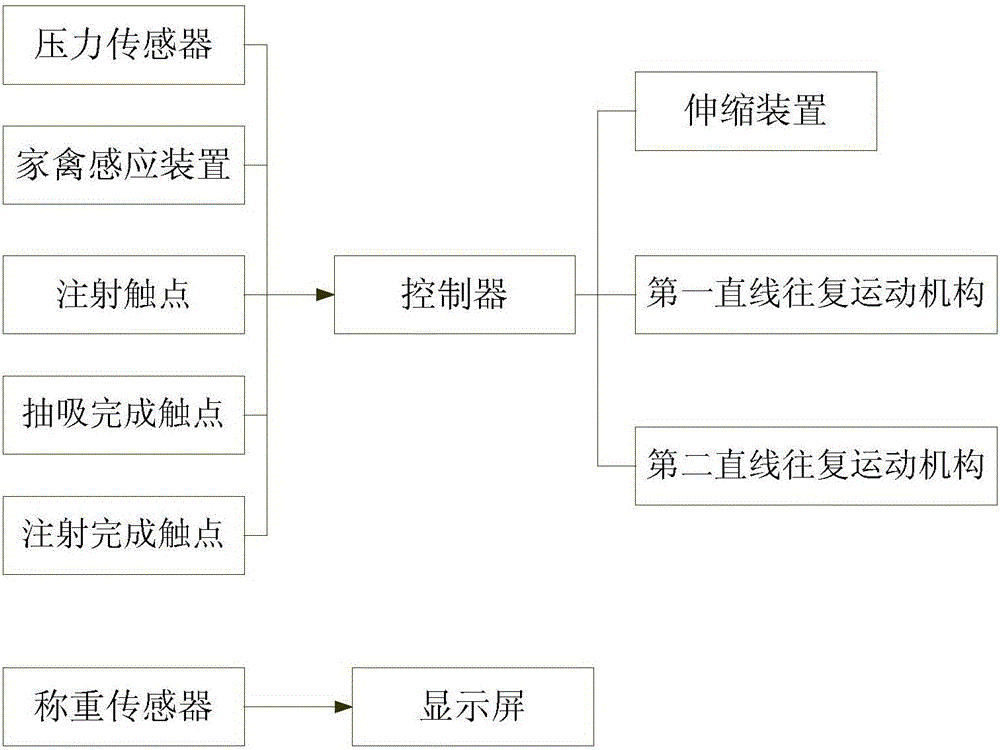

[0033] Such as Figure 1 to Figure 3 The shown automatic injection device for raising poultry and livestock includes a straight channel, in which a main shaft 1 is arranged along the direction of the inlet and outlet lines, and two clamping plates 2 are movably connected to the main shaft 1, and the two clamping plates 2 are respectively Located on both sides of the main shaft 1, a telescopic device 3 is connected between the two clamping plates 2; one of the clamping plates 2 is provided with a pressure sensor 4 and a poultry sensing device 7 on the surface facing the other clamping plate 2; The bottom surface of the channel is also provided with a load cell 5; a controller 6 is also included, the receiving end of the controller 6 is connected with the pressure sensor 4 and the poultry induction device 7 respectively, and the output end of the controller 6 is connected with the telescopic device 3; Including an injection mechanism, the injection mechanism includes a needle 11...

Embodiment 2

[0035] Such as Figure 4 The shown automatic injection device for raising poultry, on the basis of Embodiment 1, the piston core rod 15 is provided with an outwardly protruding stop block 21 on the rod body outside the syringe 12; it also includes a stepping motor 22 , the output end of the stepping motor 22 is connected to the turntable 23, the turntable 23 is located between the needle cylinder 12 and the limit block 21, and the surface of the turntable 23 facing the limit block 21 is arranged along the circumferential direction with several different lengths. Same raised 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com