An automatic injection and filling device for resin anchoring agent

A technology of resin anchoring agent and filling device, which is applied in the installation of anchor rods, mining equipment, earthwork drilling and mining, etc. It can solve the problems of high dust and high gas, harsh working environment, and low production efficiency, so as to improve safety factor and compatibility Good, the effect of large anchoring agent capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

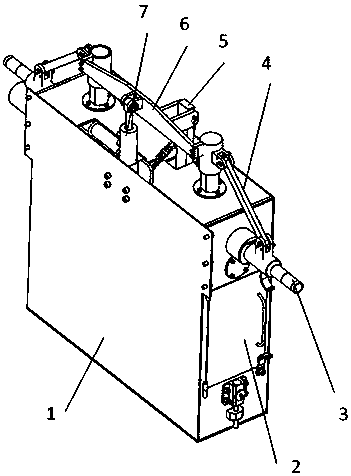

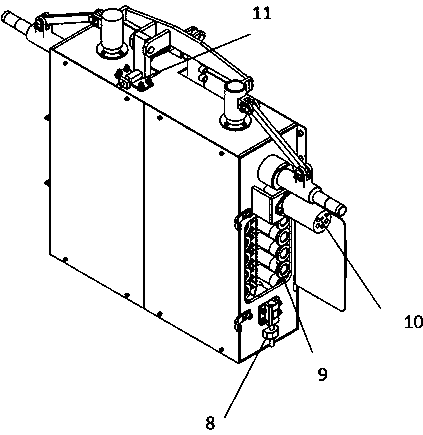

[0025] Such as figure 1 , 2 As shown, the resin anchoring agent automatic injection and filling device of the present invention consists of a main body frame 1, a charging door 2, a connecting guide nozzle 3, a coordinating connecting rod 4, a limit rod 5, a lifting connecting rod 6, a lifting cylinder 7, and a chain The tensioning mechanism 8, the conveying chain system 9, the drive motor 10 and the limit lever adjustment mechanism 11 constitute.

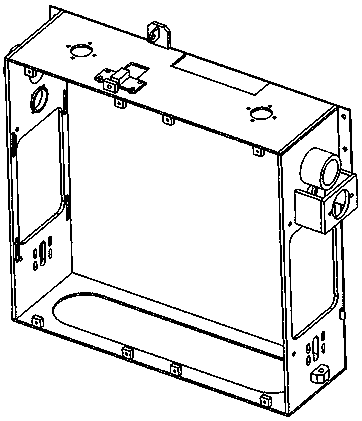

[0026] Such as image 3 As shown, the main body frame 1 is a frame structure, which constitutes the main body of the frame and acts as a load-bearing support. The front and rear direction cover plates play the role of exterior decoration dustproof. The lower side frame box plate is provided with long slotted holes, which is convenient for falling ash and coal. There are loading windows and sprocket shaft installation holes on the left and right frame box plates. Mounting holes for oil cylinders and guide shafts are reserved on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com