Impact drainage type jack hydraulic oil replacing device

A technology of hydraulic oil and jack, applied in the field of hydraulic oil replacement device of impact drainage jack, can solve the problems of low efficiency, cumbersome operation process, loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

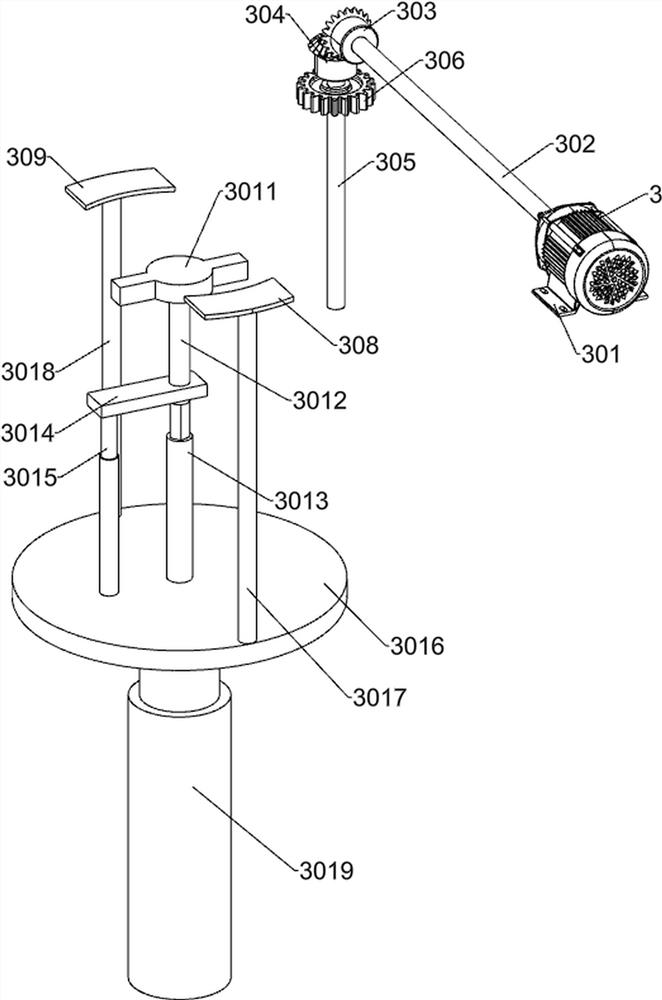

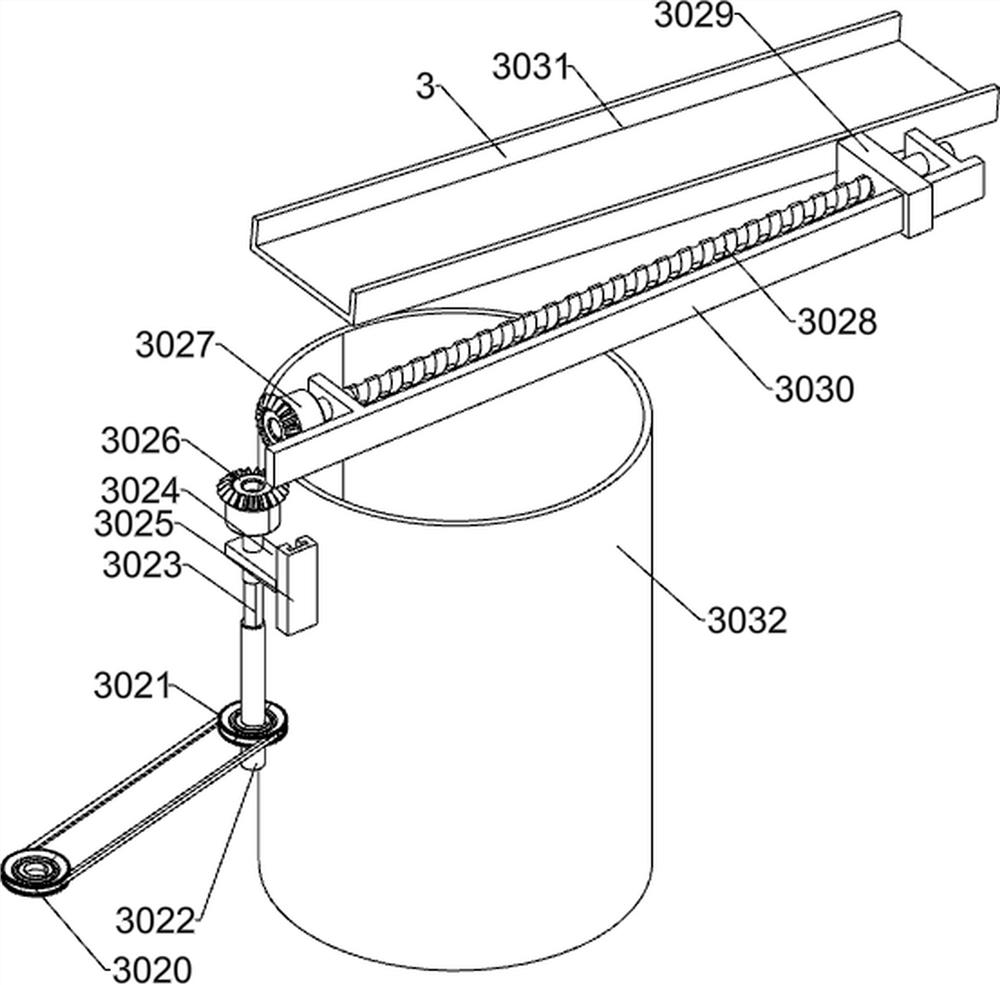

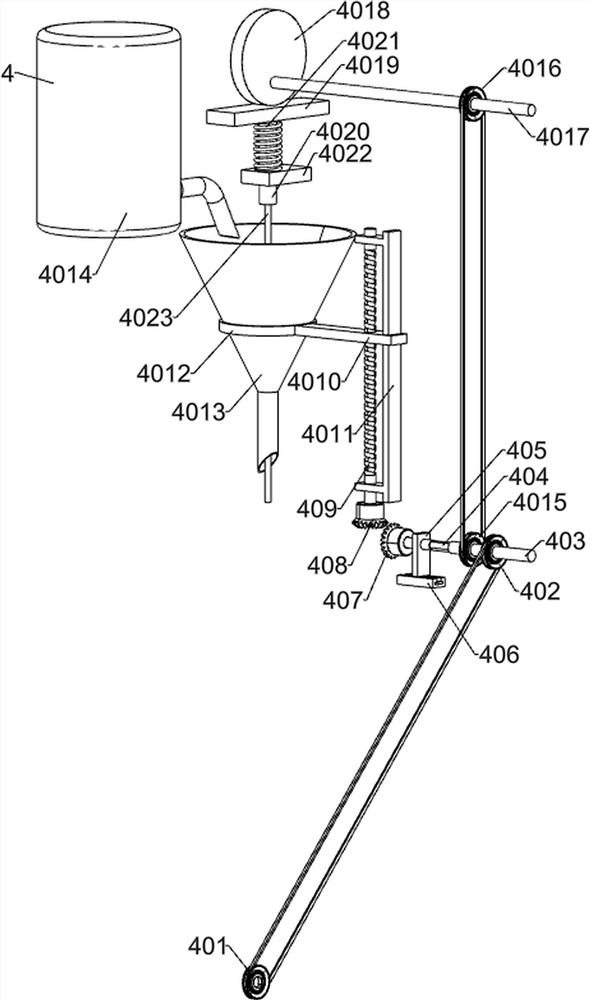

[0030] An impact drainage type jack hydraulic oil replacement device, such as Figure 1-9 As shown, it includes an underframe 1, a fixed assembly 2, an oil discharge assembly 3, an oil injection assembly 4 and a control panel 5; the underframe 1 is connected with the fixed assembly 2; the underframe 1 is connected with the oil discharge assembly 3; the underframe 1 It is connected with the oil injection assembly 4; the top of the chassis 1 is connected with the control panel 5; the oil discharge assembly 3 is connected with the oil injection assembly 4.

[0031] When preparing for work, place the device on a horizontal surface, turn on the power, put the base of the jack to be processed into the fixed assembly 2, and make the oil drain hole face down and the oil inlet hole face up, open the oil inlet hole, and then manipulate the bottom The control panel 5 control device on the frame 1 starts to operate, the jack base is fixed by the fixing component 2, so that the oil drain h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com