A Batch Processing and Forming Device for Organic Composite Insulators

A composite insulator, processing and forming technology, applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of not meeting the design requirements of multi-output devices, not being able to inject several groups of molds, and increasing the working time, so as to improve the injection molding effect. High adaptability and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

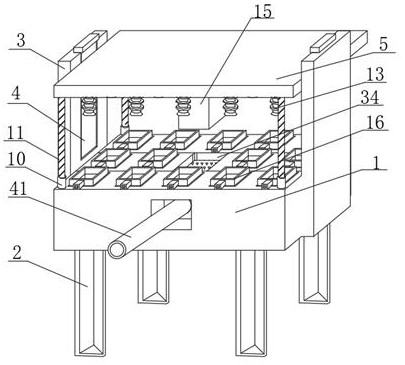

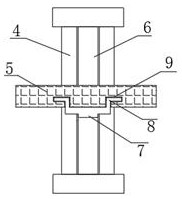

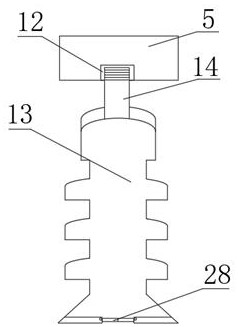

[0032] Such as Figure 1-8 As shown, a batch processing and molding device for organic composite insulators includes a workbench 1, four sets of legs 2 are welded at the four corners of the lower end of the workbench 1, and two sets of side legs are symmetrically riveted on both sides of the workbench 1. The baffle 3, the two groups of side baffles 3 are longitudinally installed with rodless cylinders 4, the two groups of rodless cylinders 4 are horizontally provided with pressing plates 5, and the rodless cylinders 4 are longitudinally provided with rails 6. A sliding seat 7 is movable on the track 6, and an L-shaped clamping plate 8 is symmetrically welded on the upper end of the sliding base 7, and a clamping hole for the L-shaped clamping plate 8 to penetrate is provided at the bottom of the pressing plate 5. Groove 9, the sheath 10 is fixedly installed at the four corners of the upper end of the workbench 1, which plays the role of protecting the sliding rod 11 and limiti...

Embodiment 2

[0039] Such as Figure 9 As shown, five groups of No. 1 solenoid valves 46 are installed inside the porous joint 43, and a high temperature resistant air bag 47 is fixedly installed on the upper end surface of the liquid material tank 37 near the side, and the gas port of the high temperature resistant air bag 47 is A No. 2 solenoid valve 48 is installed, and there is a linkage relationship between the No. 1 solenoid valve 46 and the No. 2 solenoid valve 48, and the respective flow sensors are used for linkage;

[0040] It should be noted that on the basis of the original device, this embodiment has made the following improvements. When a certain mold is damaged or disabled, and the tooling is damaged, the entire device in Embodiment 1 will not be able to operate. It is necessary to replace and repair the mold and tooling, so the No. 1 solenoid valve 46, the No. 2 solenoid valve 48 and the high-temperature-resistant air bag 47 are added. When a certain insulator mold 13 or mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com