A Gate and Container Synchronization Mechanism for High Temperature Furnace

A technology of a high-temperature furnace and a synchronizing mechanism is applied in the control of pouring molten metal from a casting ladle, metal processing equipment, casting equipment, etc. No security risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

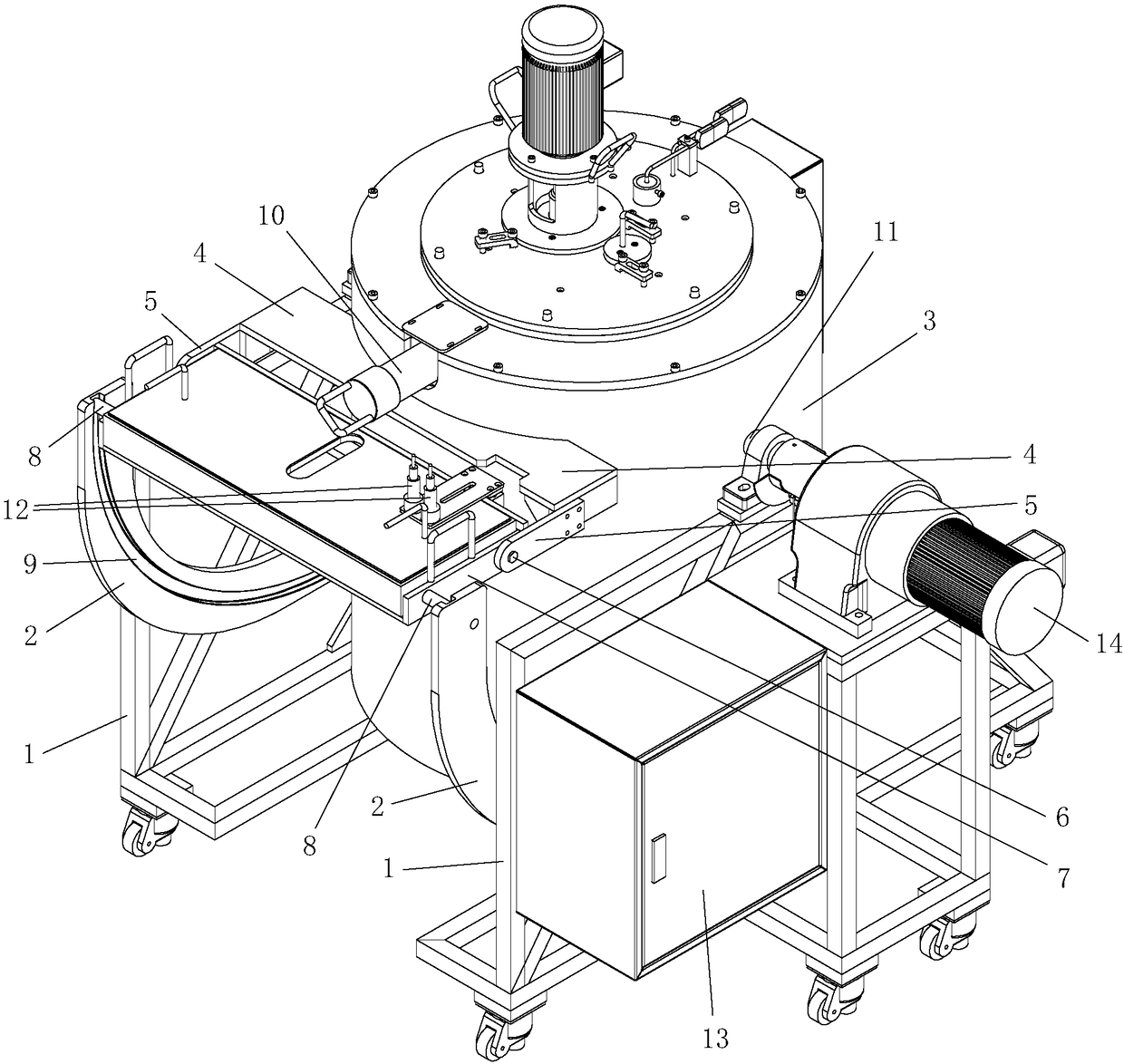

[0010] refer to figure 1 , a gate and container synchronization mechanism for high-temperature furnaces in the present invention, including two left-right symmetrical arc-shaped guide rails 2 fixed on the bottom frame 1, a support plate 4 fixed on the upper side of the high-temperature furnace body 3, supporting A synchronous arm 5 is fixedly protruded from both sides of the plate, and a mold bracket 7 is rotatably connected between the two synchronous arms through a rotating shaft 6. The rotating shaft is located inside the both sides of the mold bracket, and Sliding wheels 8 are arranged on the outside, and arc-shaped track grooves 9 are arranged on the arc-shaped guide rails. The sliding wheels are put into the arc-shaped track grooves and can slide along the arc-shaped track grooves. The frame is located directly below the gate 10 of the high-temperature melting furnace, and the two sides of the high-temperature melting furnace body are fixed with rotating shafts 11, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com