Resistance spot welding technique for steel workpiece with coating layer

A process method and resistance spot welding technology, applied in resistance welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of affecting the appearance of the car body, affecting the performance of welding joints, reducing the service life of electrodes, etc., to ensure the feasibility , the effect of suppressing splashes and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

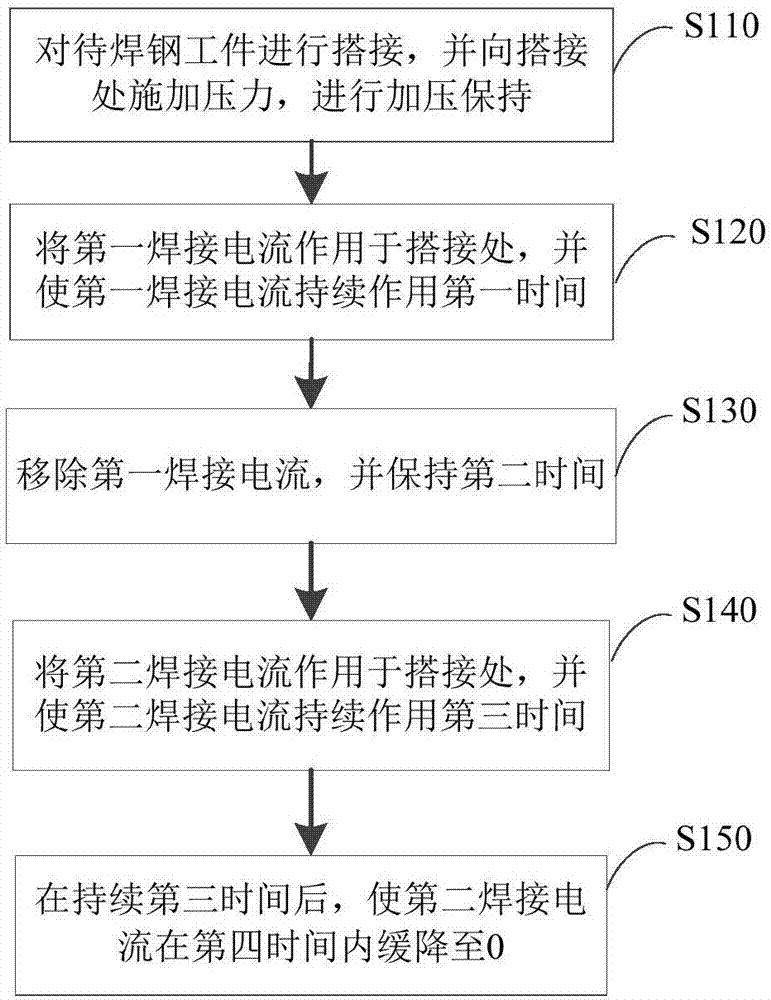

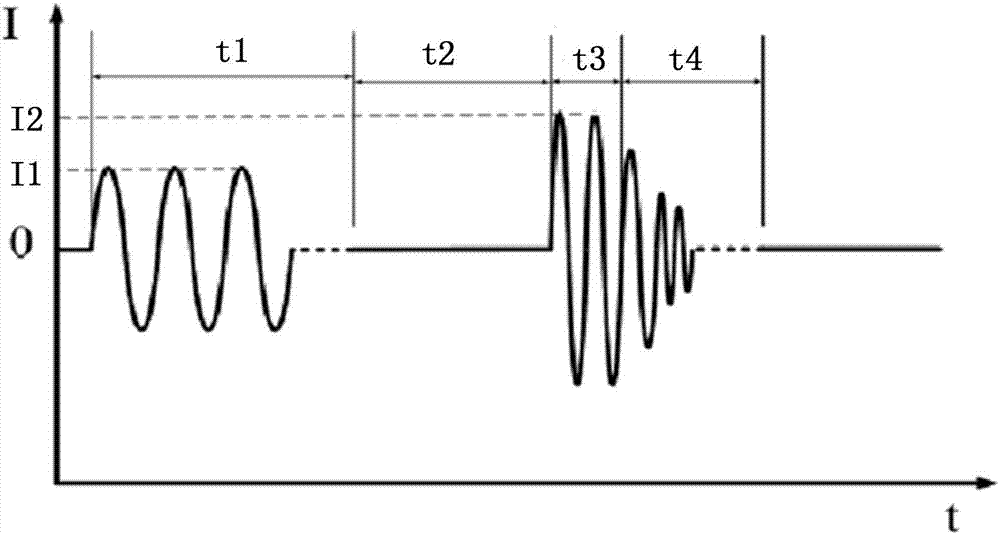

Method used

Image

Examples

Embodiment Construction

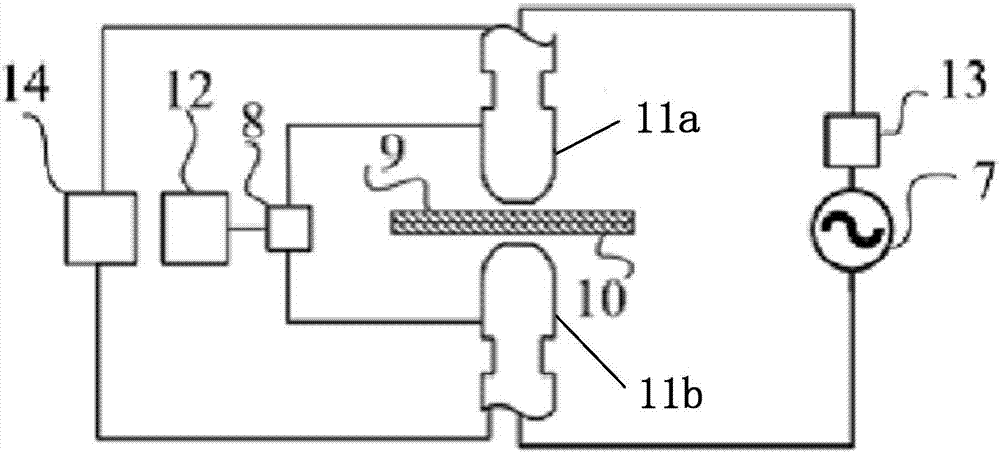

[0030] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand and implement the implementation process of how to apply technical means to solve technical problems and achieve corresponding technical effects in the present invention. The embodiments of the present application and the various features in the embodiments can be combined with each other under the premise of no conflict, and the formed technical solutions are all within the protection scope of the present invention.

[0031] In the production of automobile body manufacturing, it involves resistance spot welding of coated steel workpieces, such as the welding of DP950 galvanized coated sheets and aluminum-silicon-coated 1500MPa hot stamping sheets. The inventor studies the resistance spot welding performance of this welding relationship and finds that:

[0032] In the existing welding process, after the weldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com