Substrate treatment apparatus and substrate treatment method

A substrate processing device and substrate technology, which are applied in chemical instruments and methods, cleaning methods and utensils, and cleaning methods using liquids, etc., can solve the problems of substrate contamination, crystallization, and particle formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

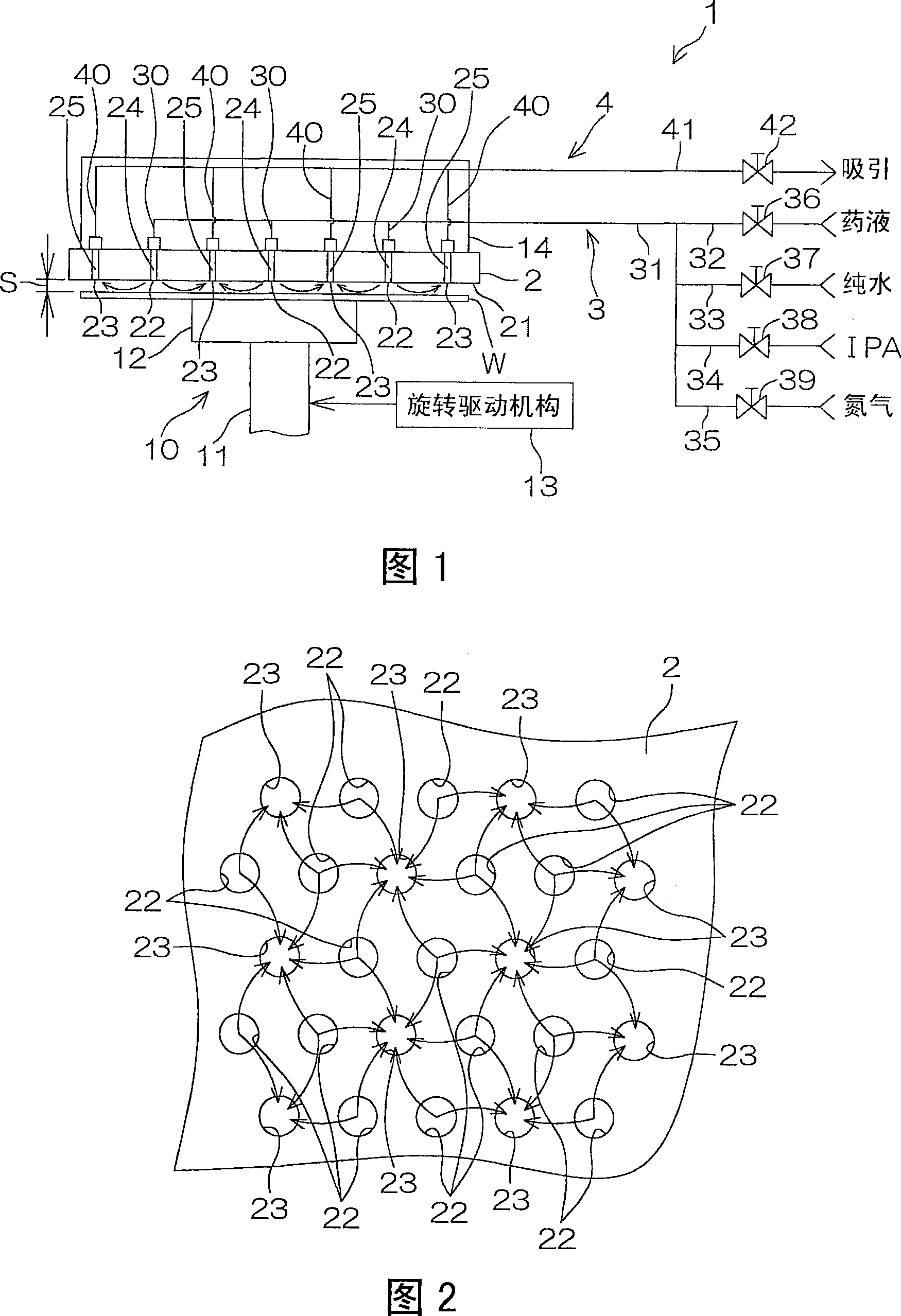

[0014] FIG. 1 is a schematic cross-sectional view showing the structure of a substrate processing apparatus according to an embodiment of the present invention.

[0015] The substrate processing apparatus 1 is a single-sheet type apparatus that performs processing with a processing liquid on the surface (upper surface) on the device forming region side of a semiconductor wafer (hereinafter referred to as "wafer") W as an example of a substrate. The substrate processing apparatus 1 includes a spin chuck 10 for rotating a wafer W held substantially horizontally, and a push-pull plate 2 for treating the surface of the wafer W held on the spin chuck 10 with a processing liquid. In addition, chemical liquid and pure water are used as the processing liquid for processing the surface of the wafer W.

[0016] The spin chuck 10 is, for example, a vacuum suction type chuck. Further, the spin chuck 10 has a rotating shaft 11 extending substantially vertically and a suction pad 12 mounte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com