Bowl type turbulence-inhibiting flow-stabilizing flow distribution device for continuous casting of thin band

A diverting device and bowl-type technology, applied in the field of molten steel steady flow distribution and pouring device, can solve the problems of molten pool liquid level fluctuation, uneven flow distribution, and uneven molten pool temperature, so as to improve the distribution, ensure normal operation, Avoid the effect of volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

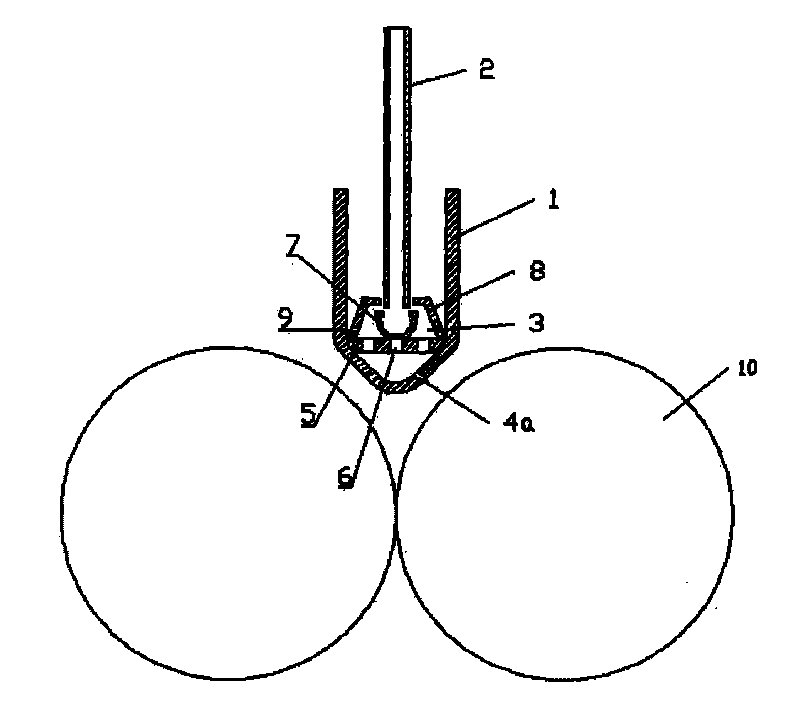

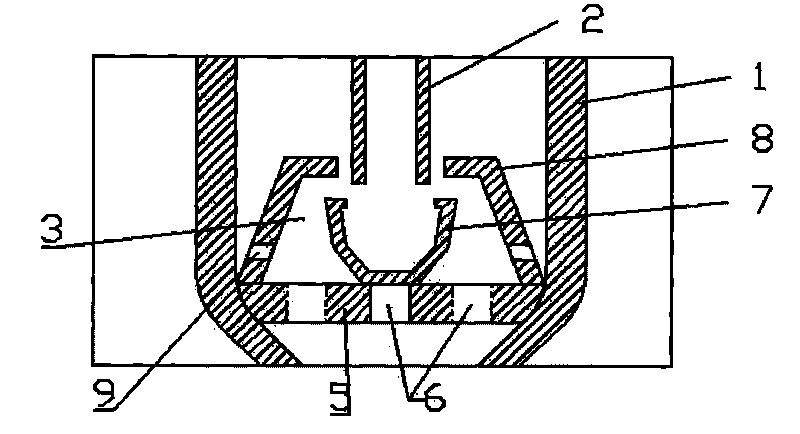

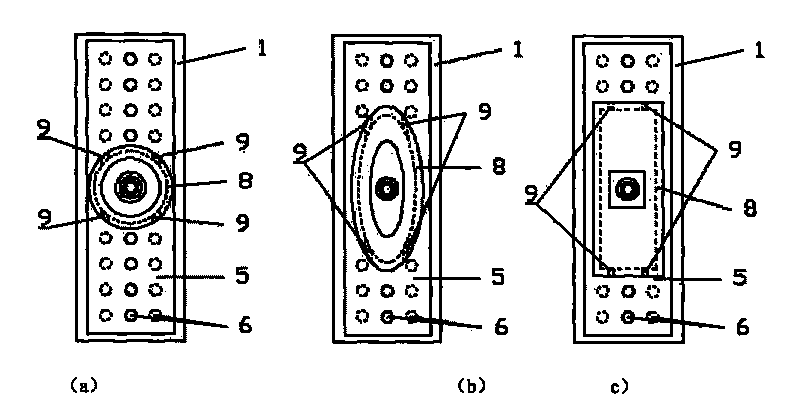

[0023] Embodiment one: see figure 1 , figure 2 , image 3 and Figure 4 , the thin strip continuous casting bowl-type turbulence suppression and steady flow distribution device includes a flow distributor 1 arranged above the rotating roller 10 and a pouring nozzle 2 extending into the cavity of the flow distributor 1, and the flow distributor 1 is "V" type Cavity structure, the upper part is an open rectangular cavity, the lower part is a narrow and long groove cavity with a "V" shape in cross section, and the lower bottom transitions with a circular arc. Orifice 4a; in the "V"-shaped long and narrow groove cavity, above the distribution flow hole 4a, there is a horizontally arranged orifice plate 5 covering the "V"-shaped long and narrow groove cavity, the orifice plate 5 1-3 rows of small holes 6 are evenly distributed along the direction of the roller axis; a bowl-type turbulence suppression and diversion device 3 is installed at the center of the orifice plate 5 . Th...

Embodiment 2

[0024] Embodiment two: see image 3 (a) Figure, the present embodiment is the same as Embodiment 1, and the special feature is that the upper and lower ends of the outer bowl 8 are circular, and there is a smooth transition between the upper and lower ends.

Embodiment 3

[0025] Embodiment three: see image 3 (b) Figure, the present embodiment is the same as the first embodiment, and the special feature is that the upper and lower ends of the outer bowl 8 are elliptical, and there is a smooth transition between the upper and lower ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com