Method and device for inhibiting coking of residue fluid catalytic disengager

A settler, oil and gas technology, used in catalytic cracking, treatment equipment corrosion/fouling inhibition, cracking, etc., can solve the problem of poor resistance to device fluctuations, catalyst runaway, increase the load of the secondary cyclone separator and catalyst runaway, oil slurry Solid content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] For a clearer understanding of the technical content of the present invention, the following examples are described in detail:

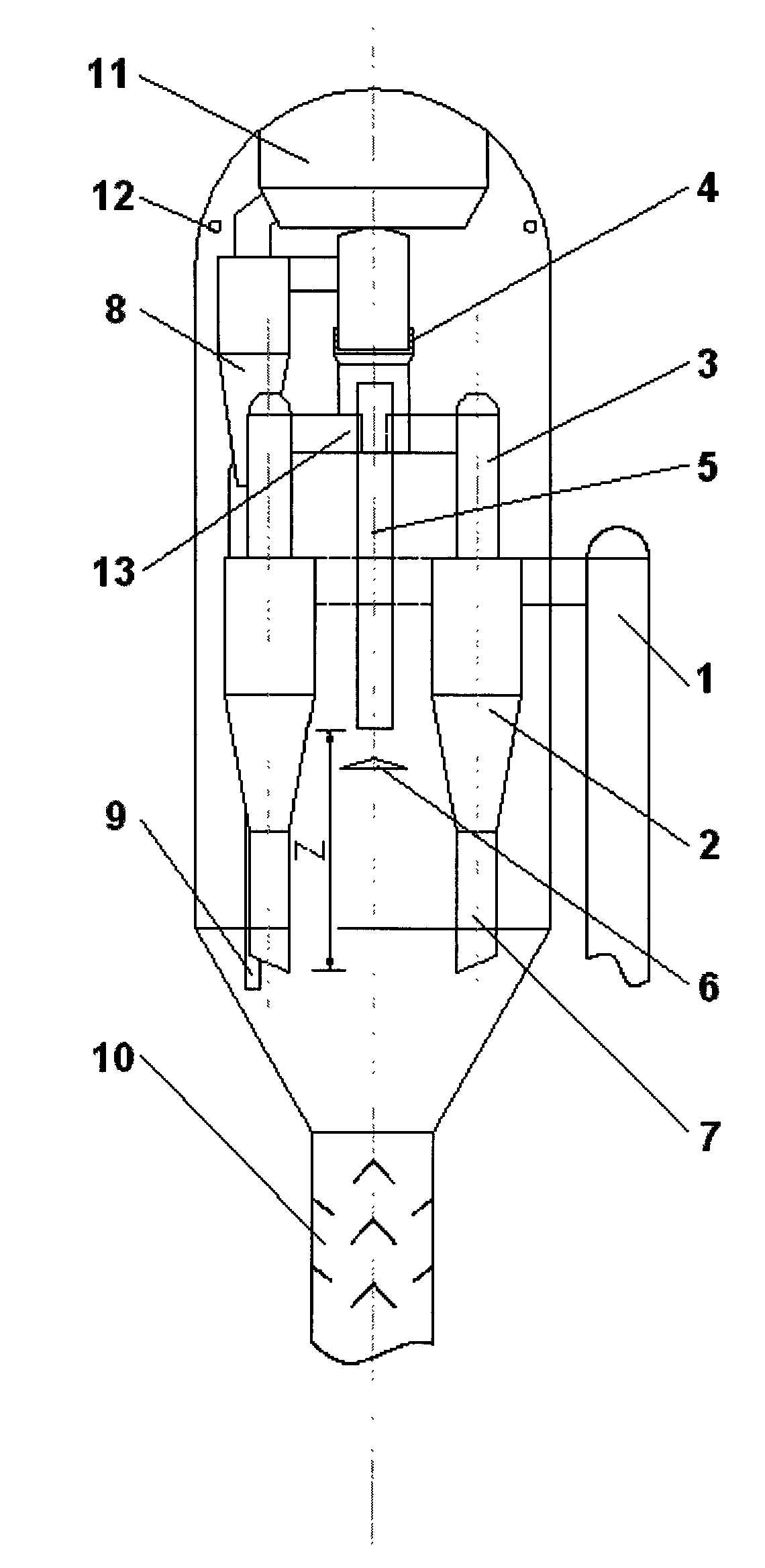

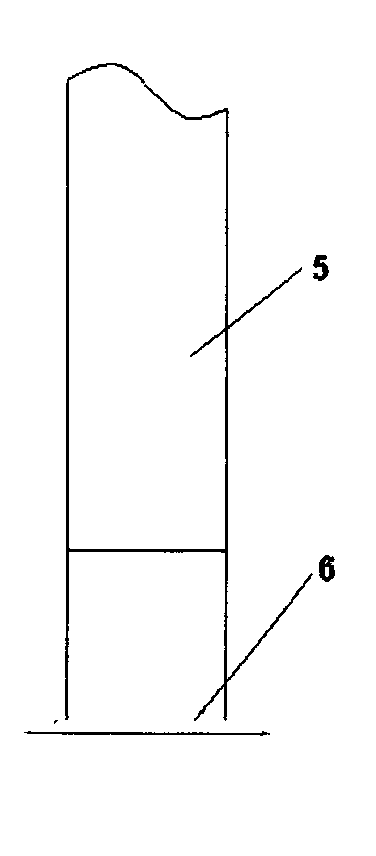

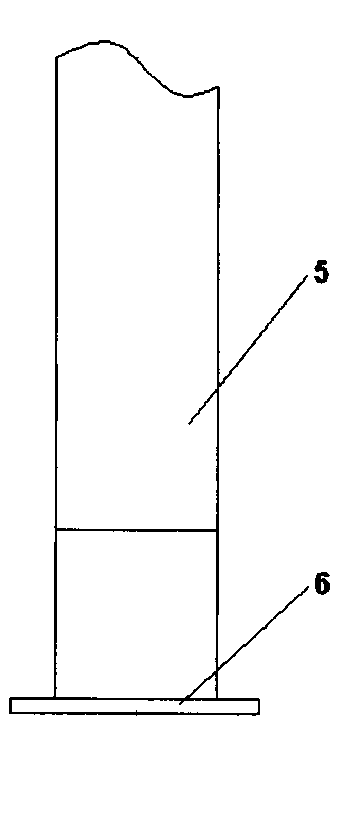

[0014] figure 1 According to the idea of the present invention, it is an embodiment of rapid extraction of oil and gas for suppressing coking in a settler. 1 is the coarse cyclone inlet section at the end of the riser reactor; 2 is the coarse cyclone separator, two or more coarse cyclones can be connected in parallel; 3 is the coarse cyclone air pipe; 4 is the socket type of the upper and lower parts of the central drainage pipe Soft connection; 5 is the central drainage tube, the lower opening of which is connected to the settlement space, and the upper part is airtightly connected to the top-swivel inlet; the central drainage tube can be one or more; 6 is the inertial separation unit at the entrance of the central drainage tube, which can be a relatively simple file Plate, gear cone, tangential groove, slot or other separation mechanism; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com