Pollution-free water-based fire extinguishing agent

A fire extinguishing agent and non-polluting technology, applied in fire prevention equipment, etc., can solve the problems of limited scope of application, poor low temperature resistance, pollution of the environment and human body, etc., and achieve fast conductivity and penetration, prevent burning, and strong penetration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

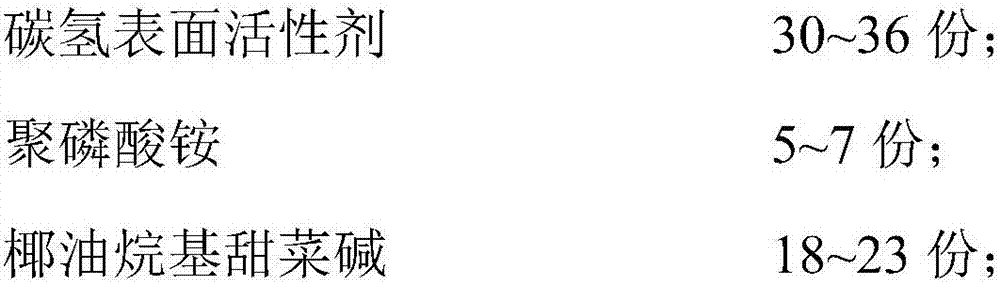

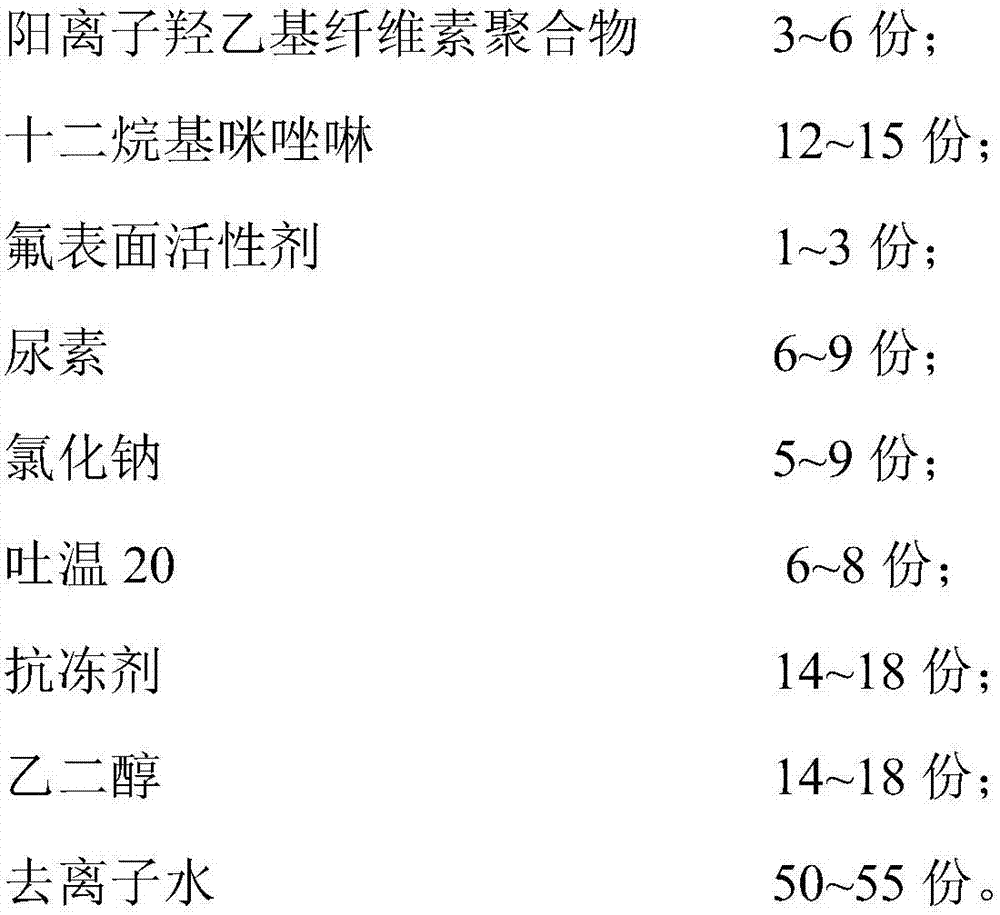

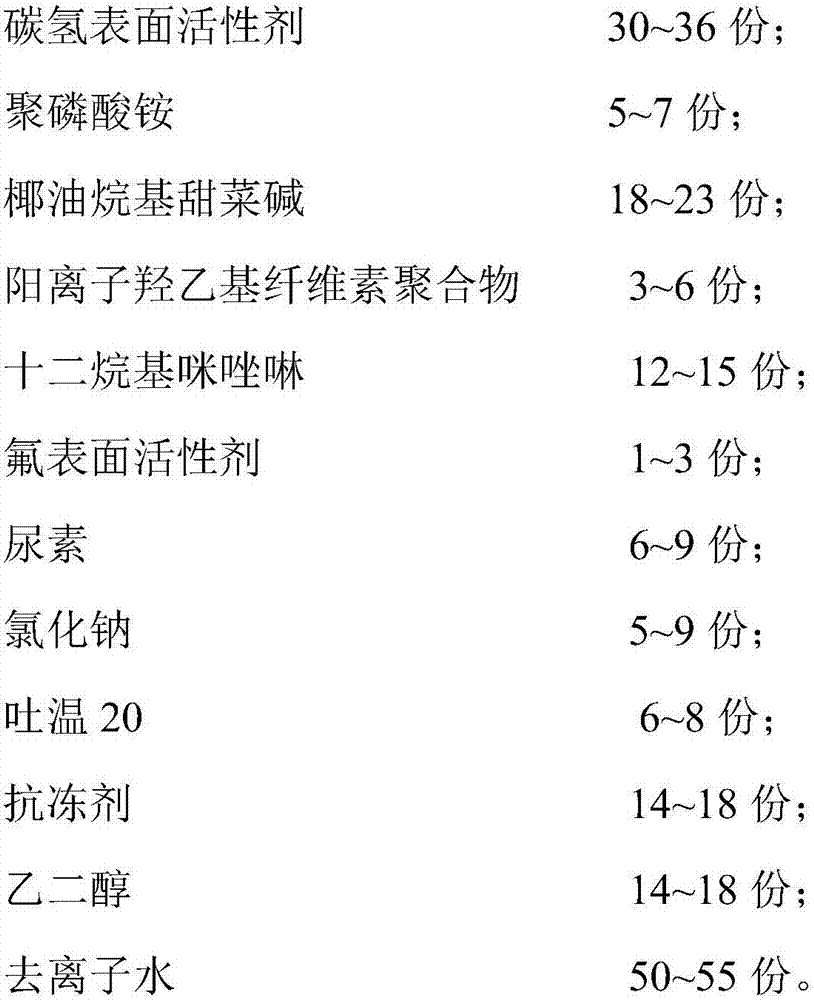

[0018] The components and the weight ratio are: 5 parts of hydrocarbon surfactant 30 ammonium phosphate; 18 parts of coconut oil alkyl betaine; 3 parts of cationic hydroxyethyl cellulose polymer; 12 parts of dodecyl imidazoline; fluorine surface 1 part of active agent; 6 parts of urea; 5 parts of sodium chloride; 6 parts of Tween 20; 14 parts of antifreeze; 14 parts of ethylene glycol; 50 parts of deionized water.

Embodiment 2

[0020] The components and the weight ratio are: 31 parts of hydrocarbon surfactant; 6 parts of ammonium polyphosphate; 19 parts of coconut oil alkyl betaine; 4 parts of cationic hydroxyethyl cellulose polymer; 13 parts of dodecyl imidazoline. 2 parts of fluorosurfactant; 7 parts of urea; 6 parts of sodium chloride; 7 parts of Tween 20; 15 parts of antifreeze; 15 parts of ethylene glycol; 51 parts of deionized water.

Embodiment 3

[0022] The components and the weight ratio are: 33 parts of hydrocarbon surfactant; 7 parts of ammonium polyphosphate; 20 parts of coconut oil alkyl betaine; 5 parts of cationic hydroxyethyl cellulose polymer; 14 parts of dodecyl imidazoline ; 3 parts of fluorosurfactant; 8 parts of urea; 7 parts of sodium chloride; 8 parts of Tween 20; 16 parts of antifreeze; 16 parts of ethylene glycol; 53 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com