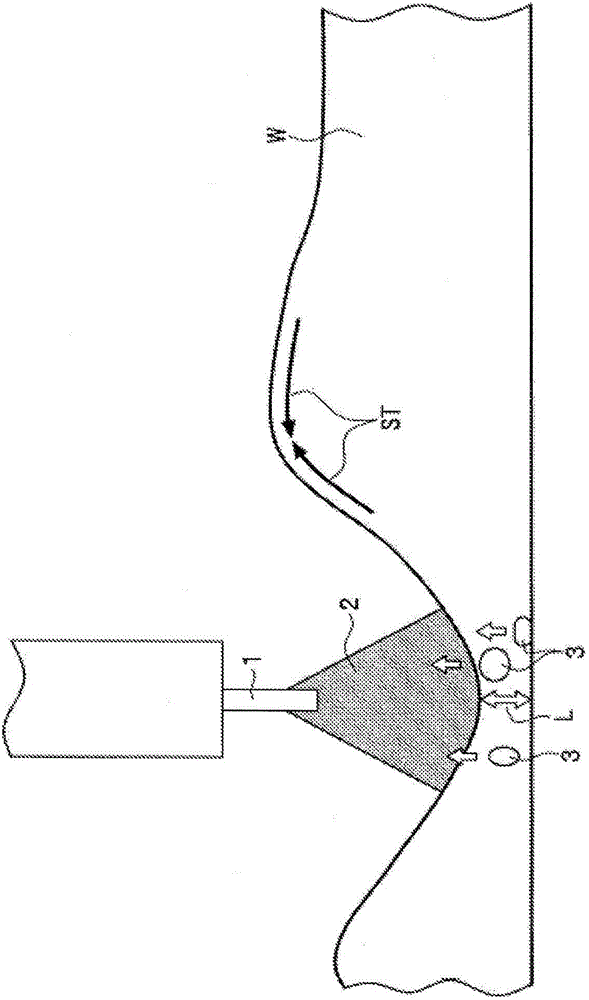

Solid wire, and gas-shielded arc welding method using same

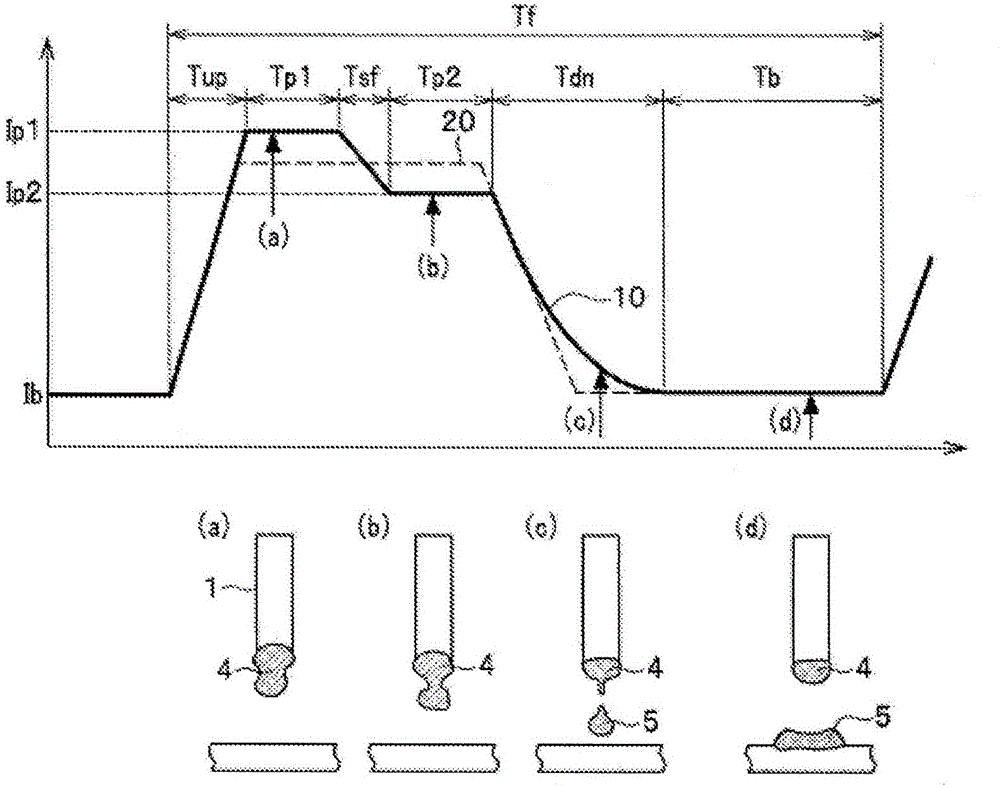

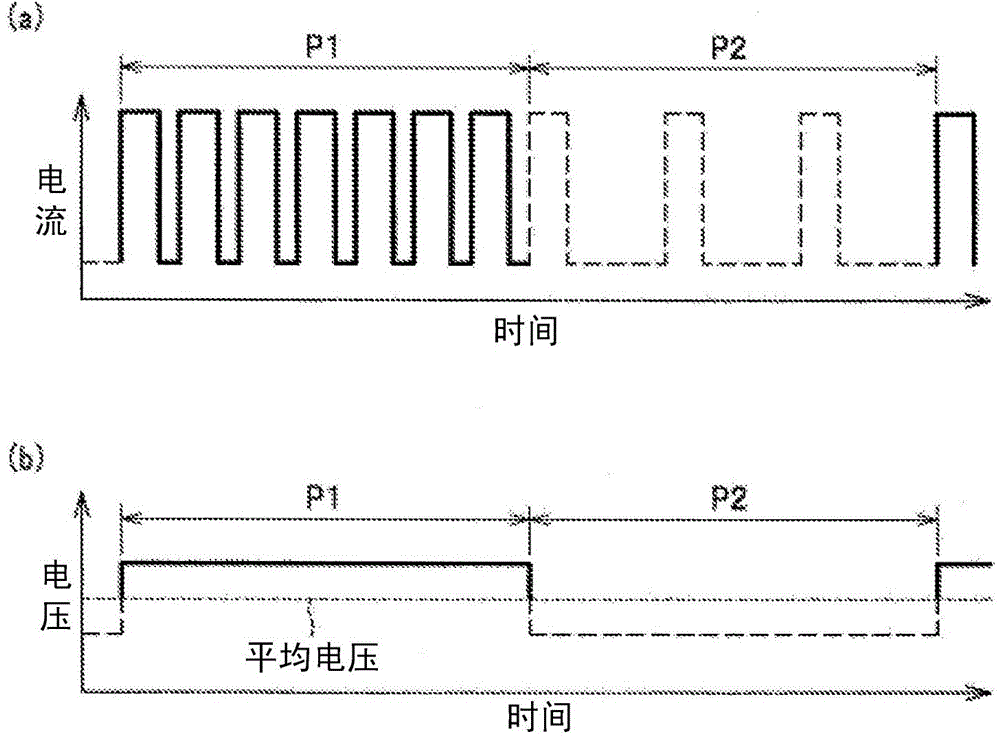

A solid wire, gas shielded technology, used in arc welding equipment, welding/welding/cutting items, welding media, etc., can solve the problems of excessive reduction, insufficient surface tension, porosity defects, etc. of the molten pool, and achieve the appearance of the weld bead. Excellent, improved surface tension, stable shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0147] Next, examples that satisfy the requirements of the present invention and comparative examples that do not satisfy the requirements of the present invention are illustrated, and the solid welding wire of the present invention and a gas shielded arc welding method using the same will be described.

[0148] (solid wire, shielding gas)

[0149] As the solid welding wires, solid welding wires having the compositions shown in Table 1 (wire Nos. W1 to W42) were used.

[0150] 【Table 1】

[0151]

[0152] Except for Test No. 13 (wire No. W13) in Table 1, Cu plating (0.20% by mass of Cu relative to the total mass of the wire) was performed on the surface of the solid wire. In addition, the welding wire No. of Table 2A-5 mentioned later corresponds to the welding wire No. of Table 1. In addition, the composition of the shielding gas used is shown in Tables 2A-5.

[0153] (base material)

[0154] The base material is SGCC (hot-dip galvanized steel sheet) based on JIS G 3302...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com