Multielectrode gas-shield arc welding method and device

A shielded arc and multi-electrode technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as welding defects in welded parts, achieve reliable stability, excellent weld bead appearance and shape, and increase productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0139] Hereinafter, modes for implementing the multi-electrode gas-shielded arc welding method and the multi-electrode gas-shielded arc welding apparatus of the present invention will be described in detail with reference to the drawings as appropriate.

[0140] First, a multi-electrode gas-shielded arc welding device will be described, and then a multi-electrode gas-shielded arc welding method will be described.

[0141] "Multi-electrode gas shielded arc welding device"

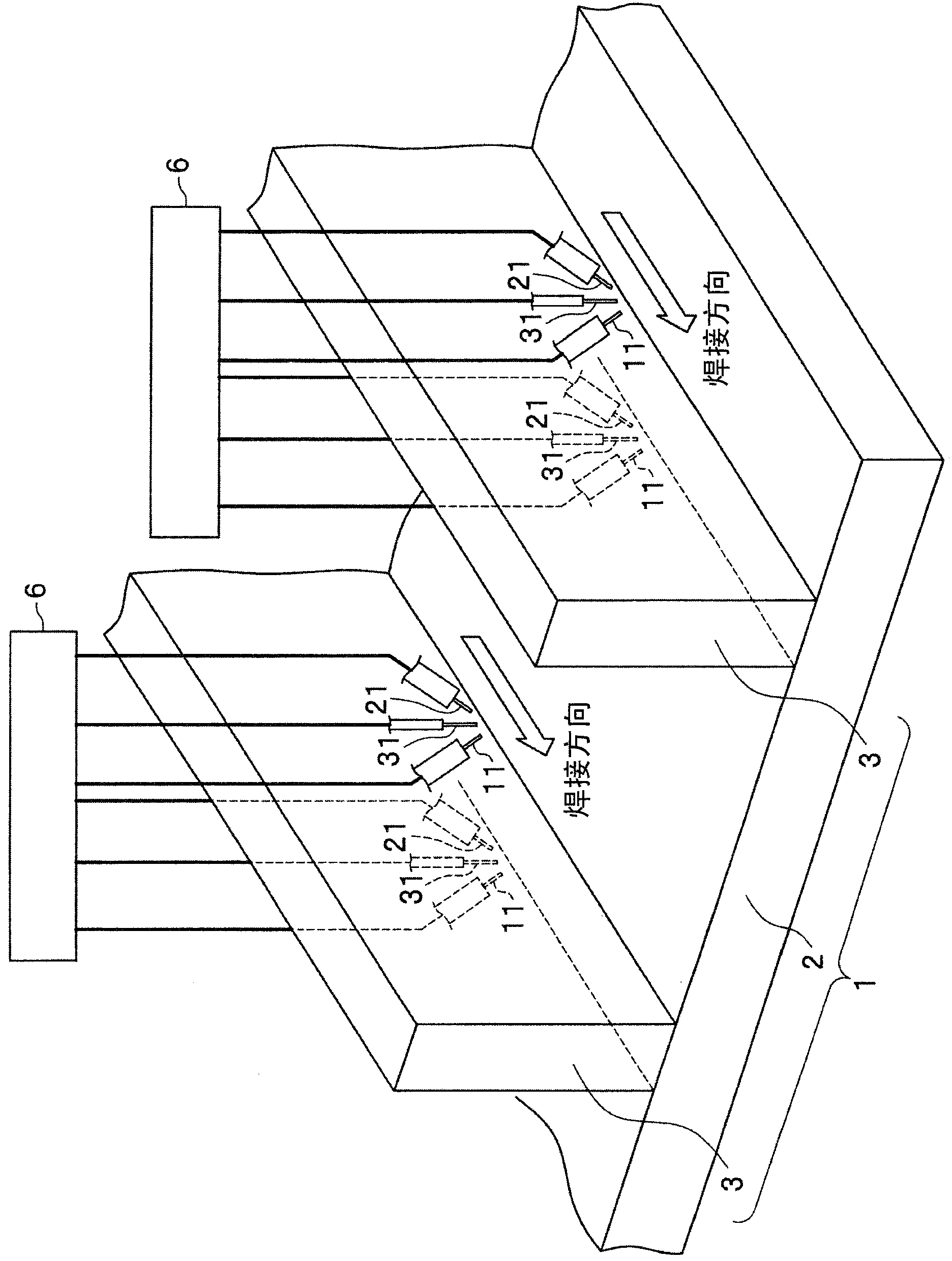

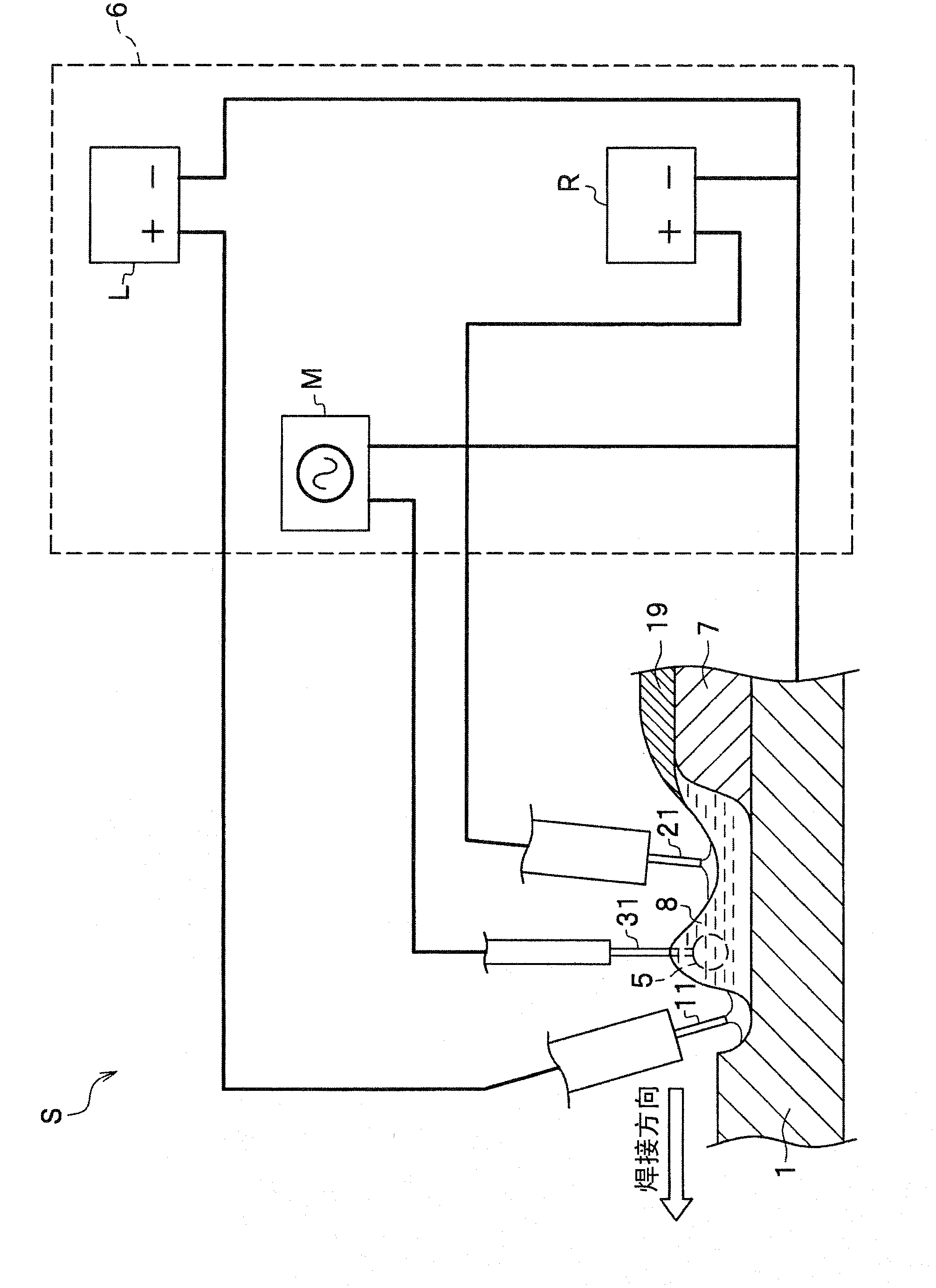

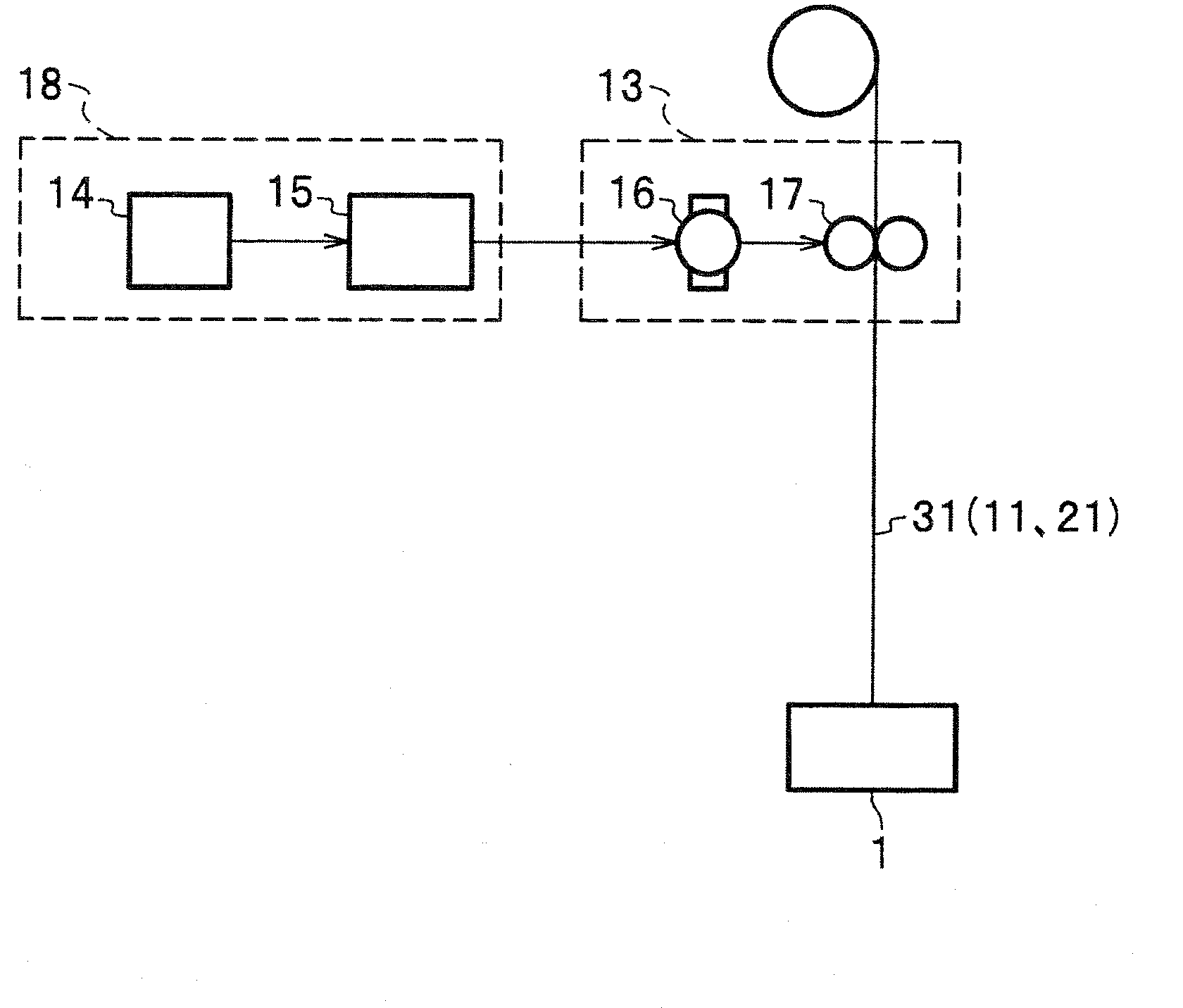

[0142] Such as figure 1 , 2 As shown, a multi-electrode gas shielded arc welding device S (hereinafter, appropriately referred to as a welding device S) includes a preceding gas shielded arc welding electrode 11 (hereinafter, appropriately referred to as a leading electrode 11) and a subsequent gas shielded arc welding electrode 21 (hereinafter, It is appropriately referred to as a subsequent electrode 21 ), and an intermediate electrode 31 is further provided between the preceding electrode 11 and the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com