Patents

Literature

62results about How to "Good welding condition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

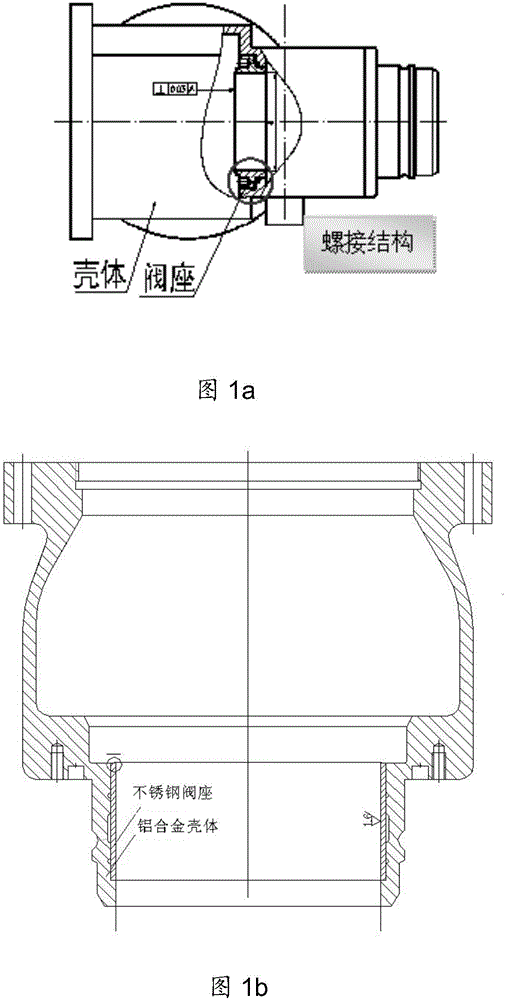

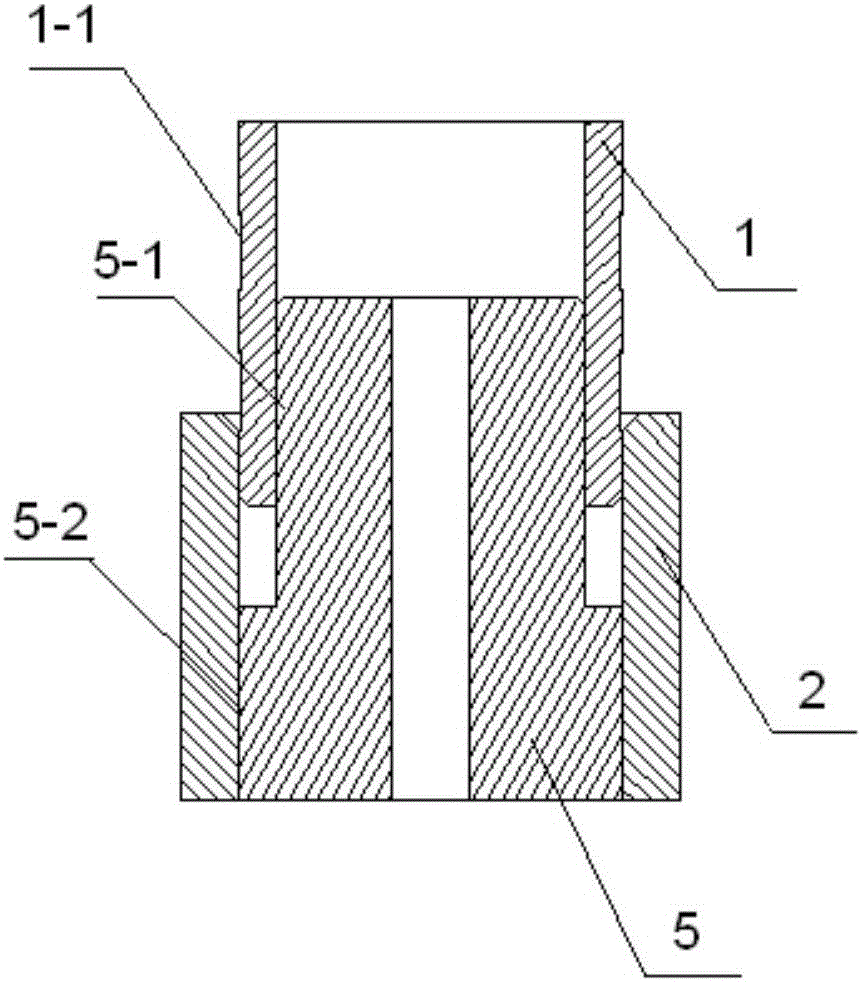

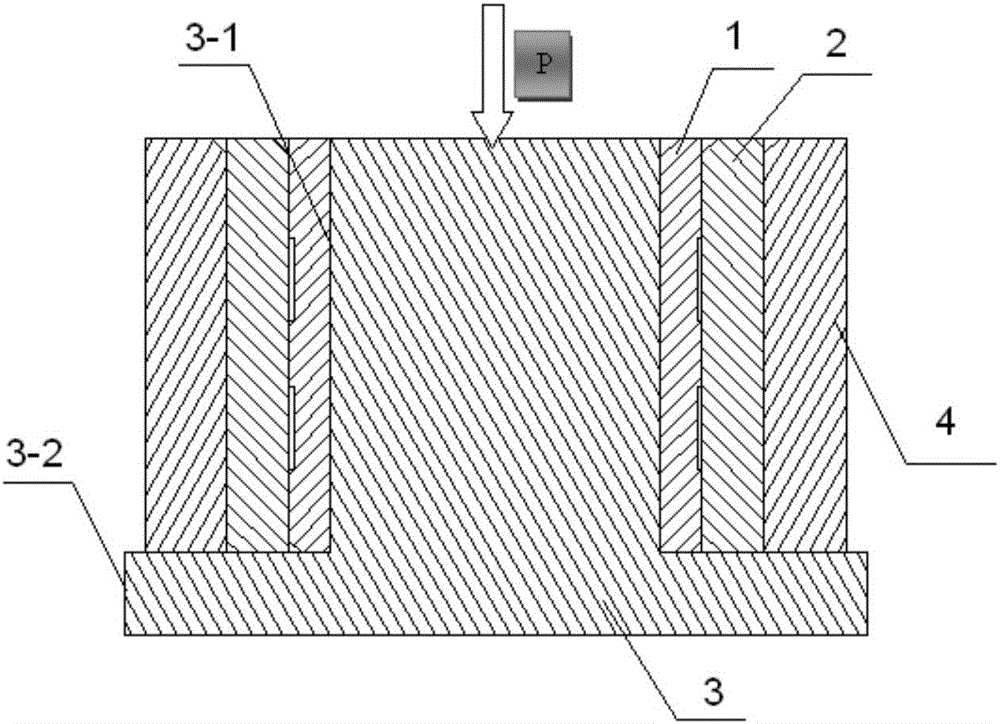

Diffusion welding method of dissimilar metal

ActiveCN106808078AGuarantee welding qualityGuaranteed coaxialityWelding/soldering/cutting articlesNon-electric welding apparatusAxial pressureConcentration gradient

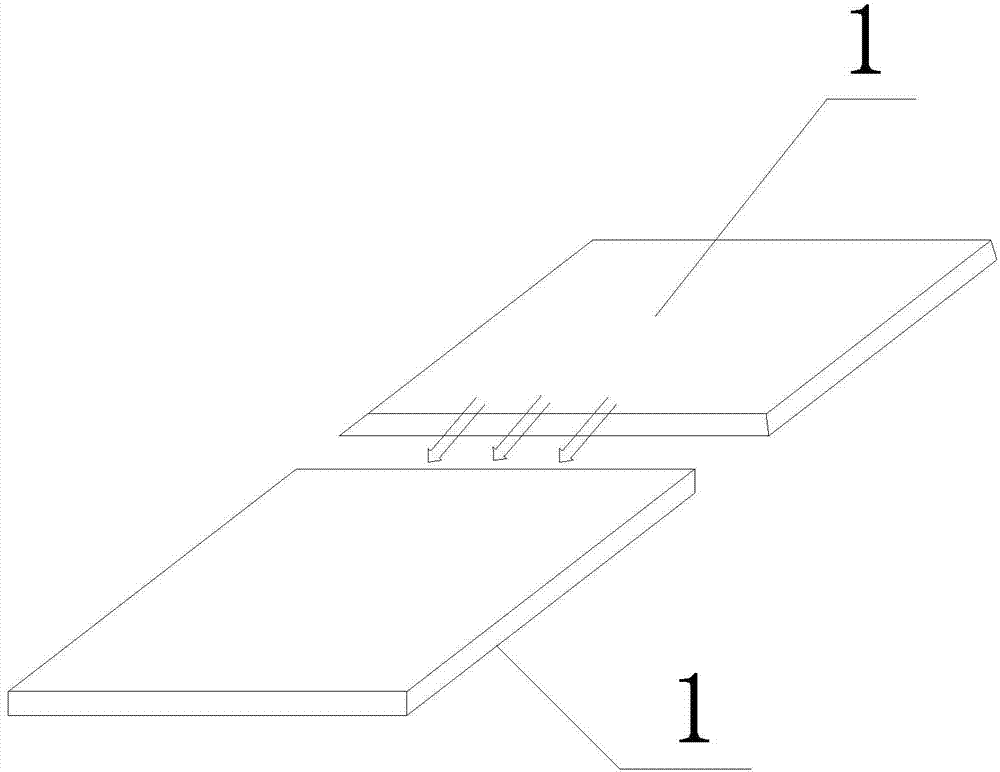

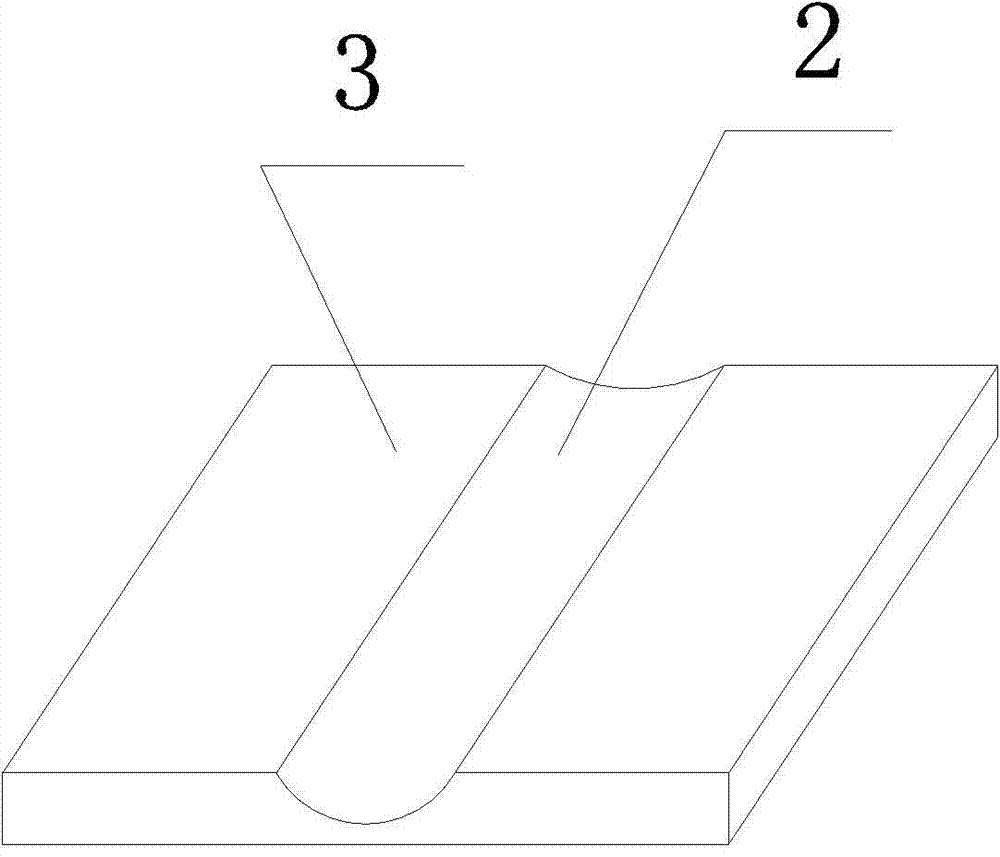

The invention relates to a diffusion welding method of dissimilar metal. A specially designed outer side limiting tool and an inner support tool are adopted for thermal expansion constraint in the welding process of an assembled to-be-welded dissimilar metal part, thus, sufficient and even welding pressure on the radial welding face is obtained, and reliable welding guarantee is provided for diffusion welding of the dissimilar metal. The expansion constraint pressurizing idea is provided by the invention for dissimilar metal interface radial pressurizing, radial expansion of the to-be-welded part is constrained through an inner side limiting tool and the outer side limiting tool, and axial expansion of the to-be-welded part is constrained through axial pressure applied by a diffusion welding device or tool, so that expansion pressure is effectively applied to the welding interface of the dissimilar metal, and the dissimilar metal weld part with good joint performance and airtightness is obtained; and the seaming condition of the whole welding interface is good, obvious concentration gradient of the welding interface exists, and the diffusion characteristic is met.

Owner:CAPITAL AEROSPACE MACHINERY +1

Zinc-aluminium alloy silk containing rare earth and producing process thereof

The present invention is RE containing Zn-Al alloy wire and its preparation process, and the RE containing Zn-Al alloy is used as the end spraying material for metallized film capacitor. The RE containing Zn-Al alloy contains Al 4-16 wt%, RE mixture with light RE as main components 0.01-0.12 wt%, and impurity not more than 0.025 wt% except Zn. The preparation process includes pouring Al molt into Zn molt, raising the temperature for melting while stirring, adding intermediate RE alloy, and smelting while stirring to obtain the RE containing Zn-Al alloy. The RE containing Zn-Al alloy wire of the RE containing Zn-Al alloy has compact structure, improved machining performance and use performance, and improved welding condition.

Owner:戴国水

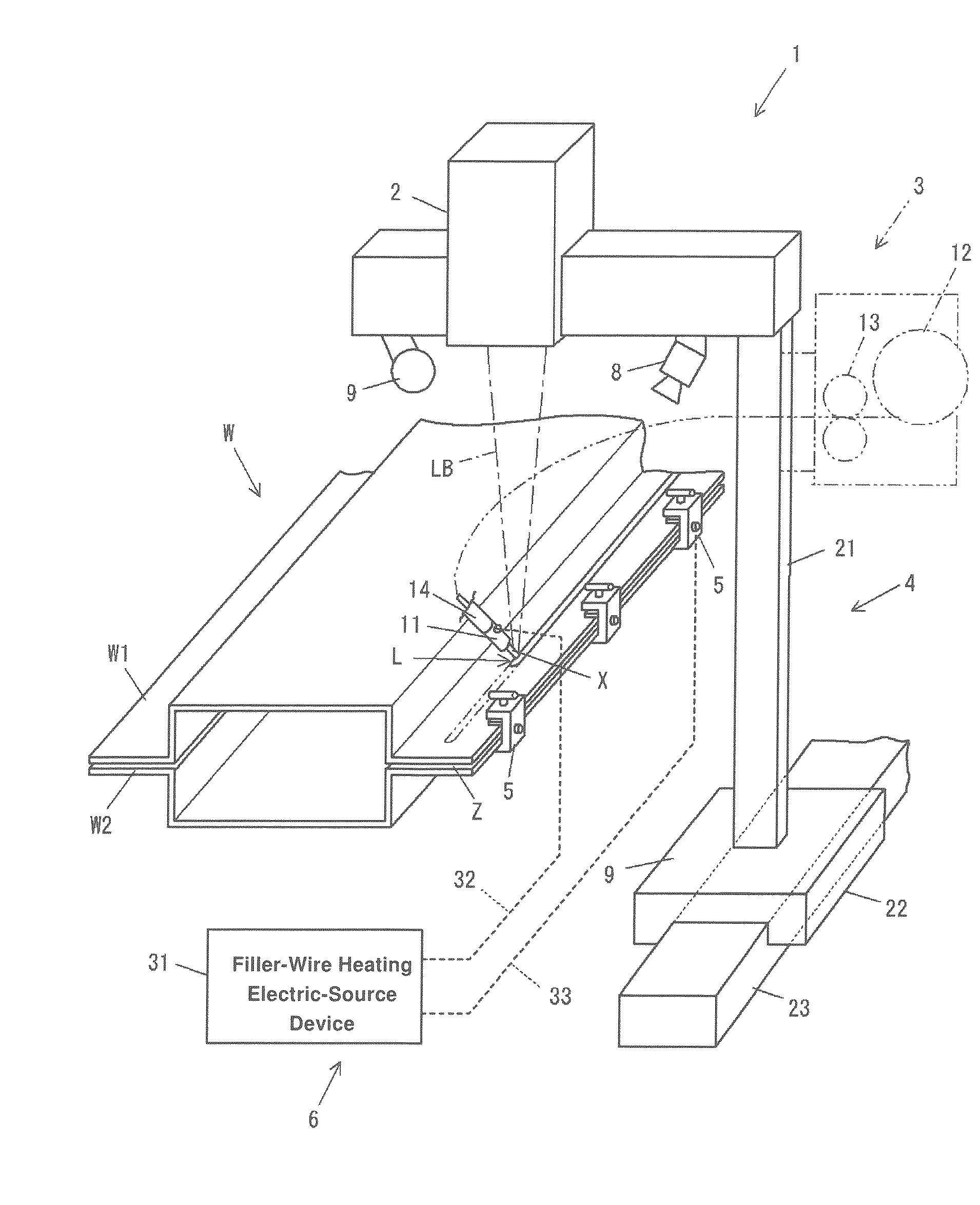

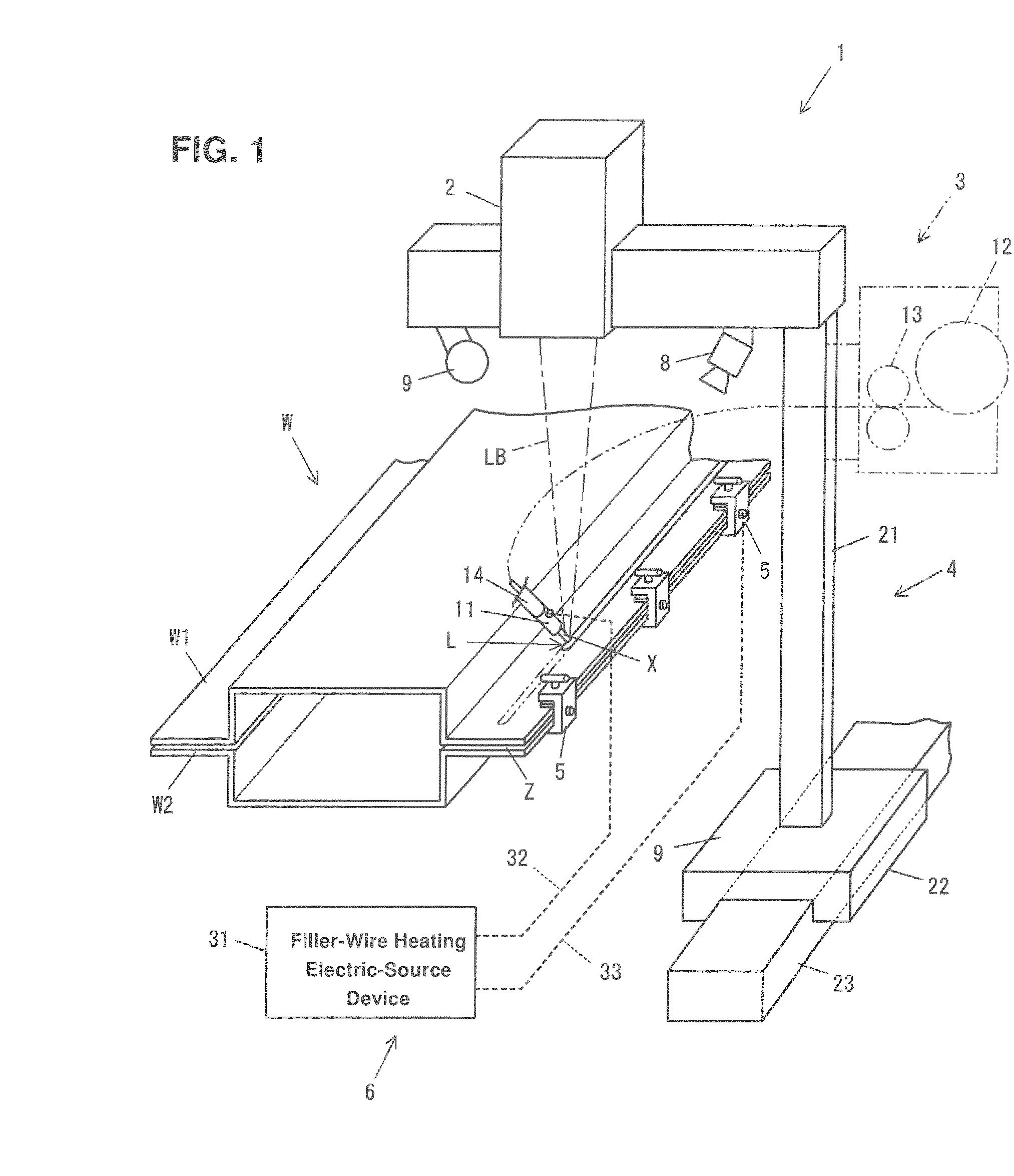

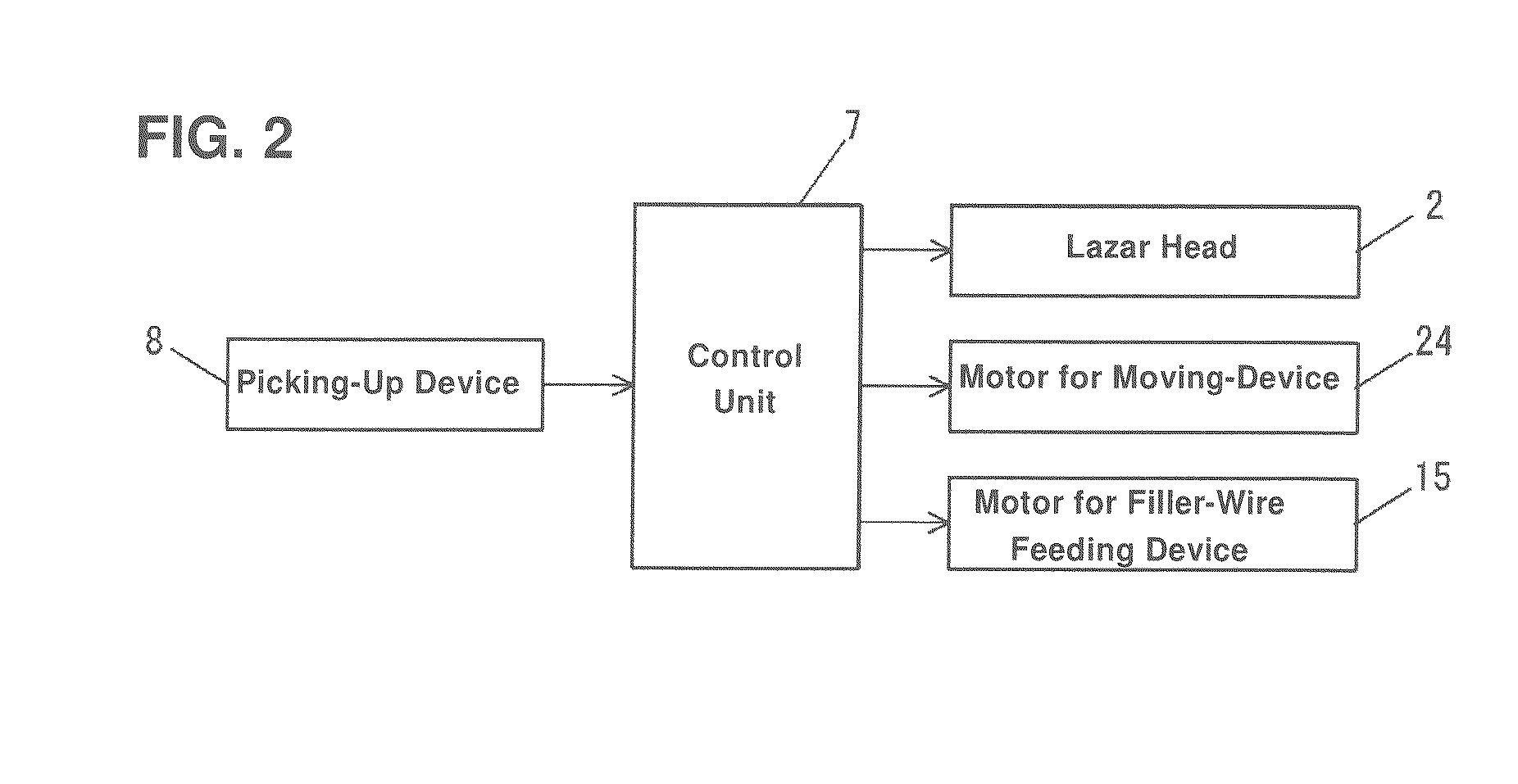

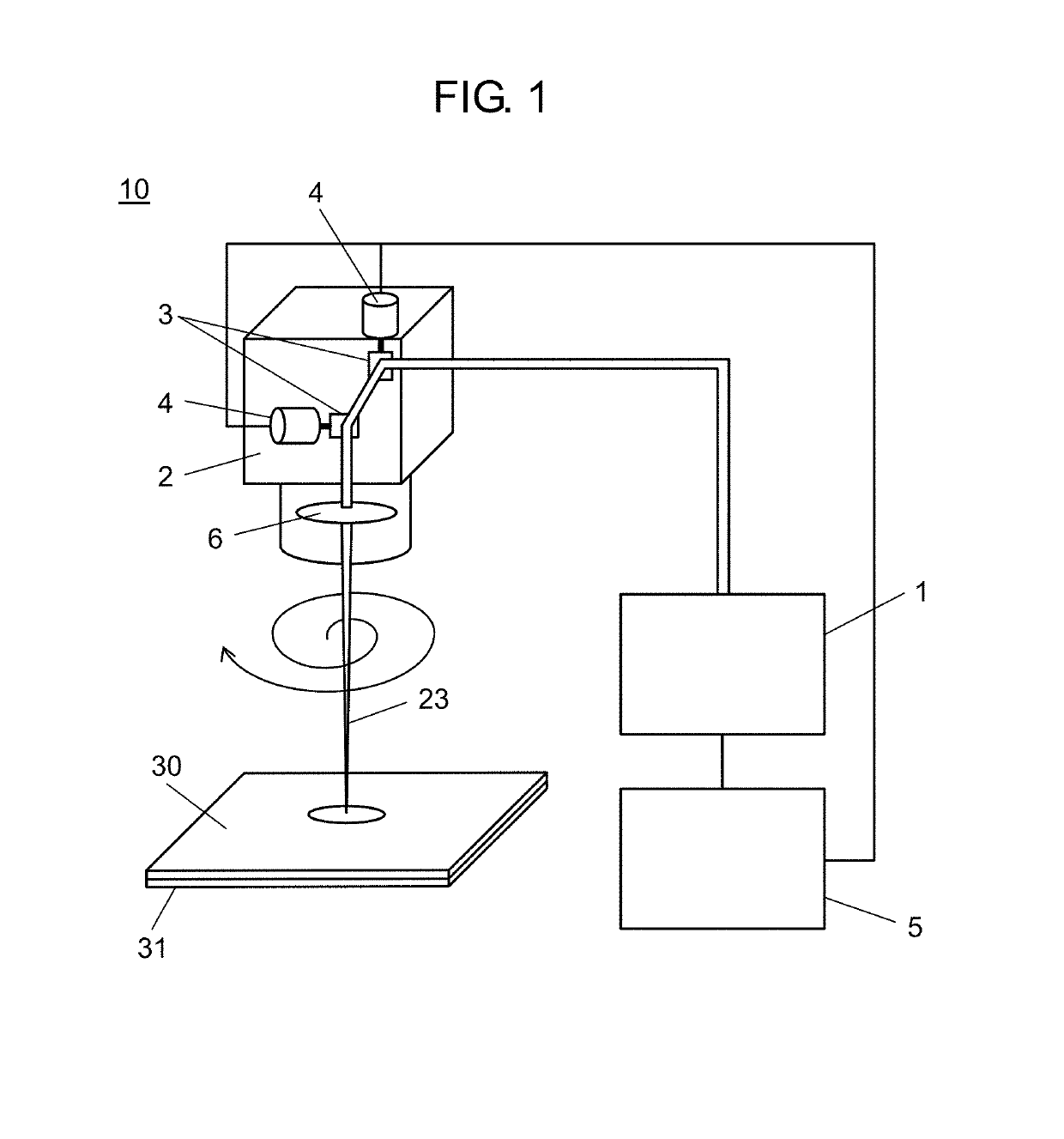

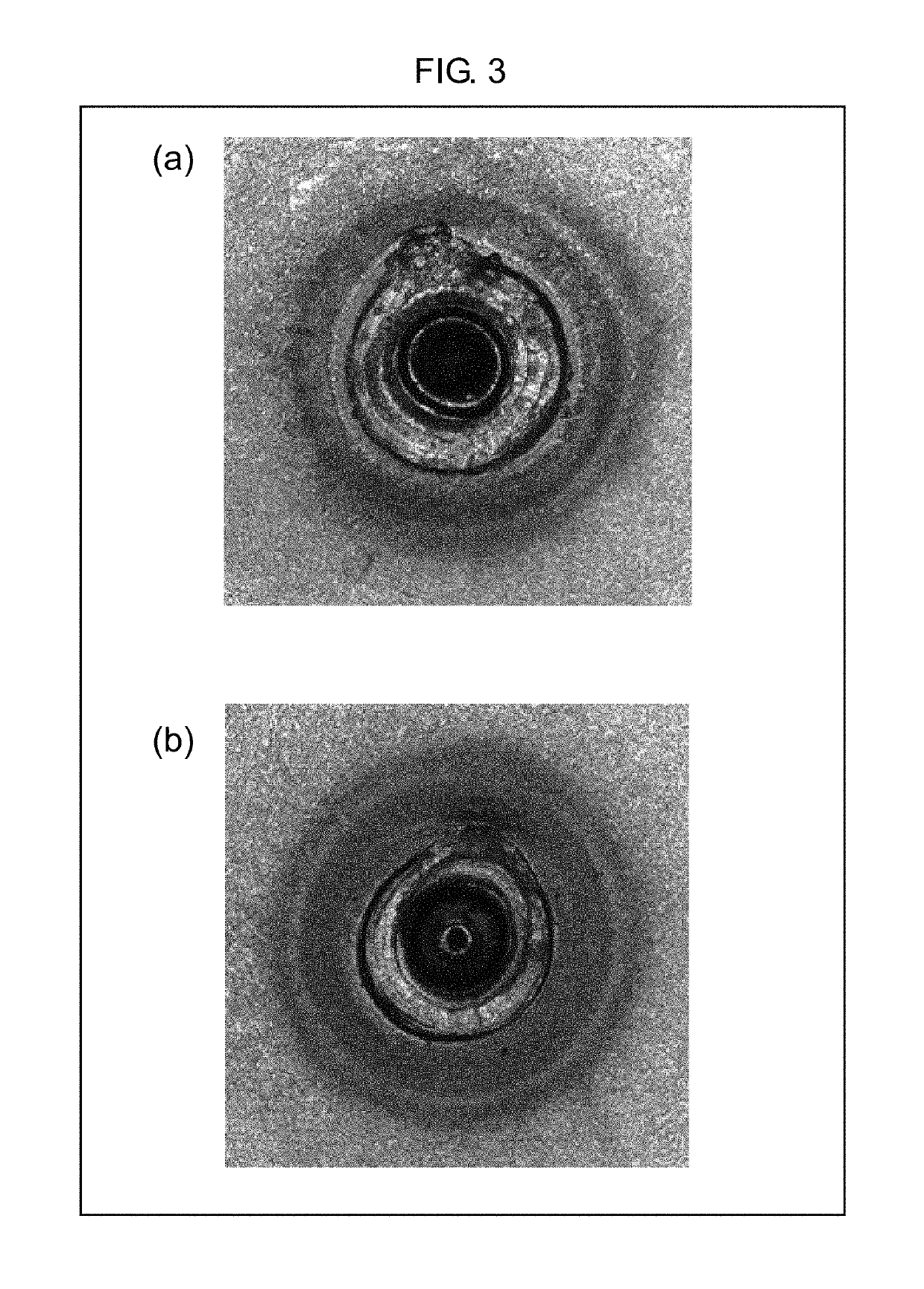

Laser welding method and apparatus

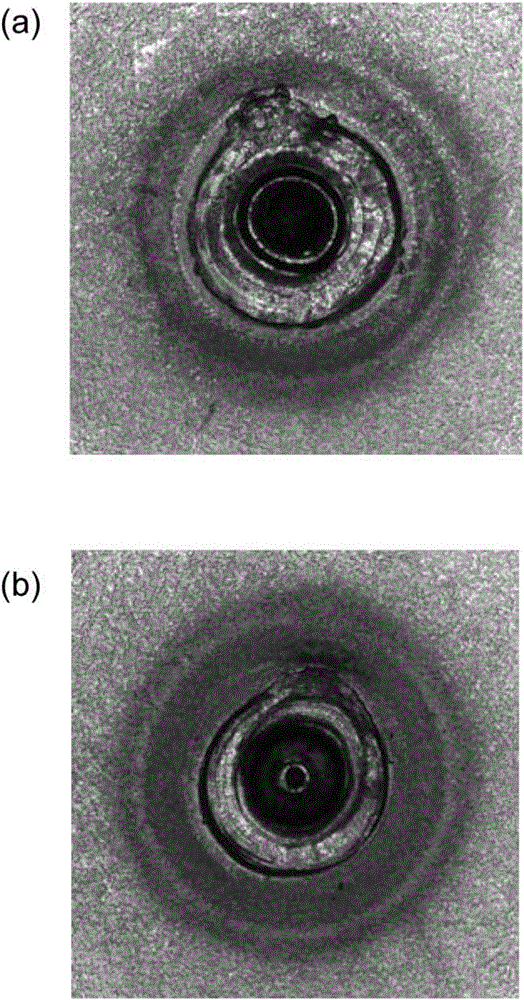

InactiveUS20100206856A1Precision weldingMade preciselyLaser beam welding apparatusLaser beamsMolten pool

A laser welding method including a step of welding upper and lower metal plates, a step of picking up an image of a molten pool near a molten hole from the side of the upper metal plate during an execution of the welding step, a step of determining whether a welding state of the metal plates is proper or not by analyzing a generation state of the molten pool based on the image picked up in the picking-up step, and a step of adjusting at least one of a parameter of the irradiated laser beams and a feeding speed of the filler wire so that the welding state of the metal plates becomes proper in case the welding state determined in the determining step is not proper.

Owner:MAZDA MOTOR CORP

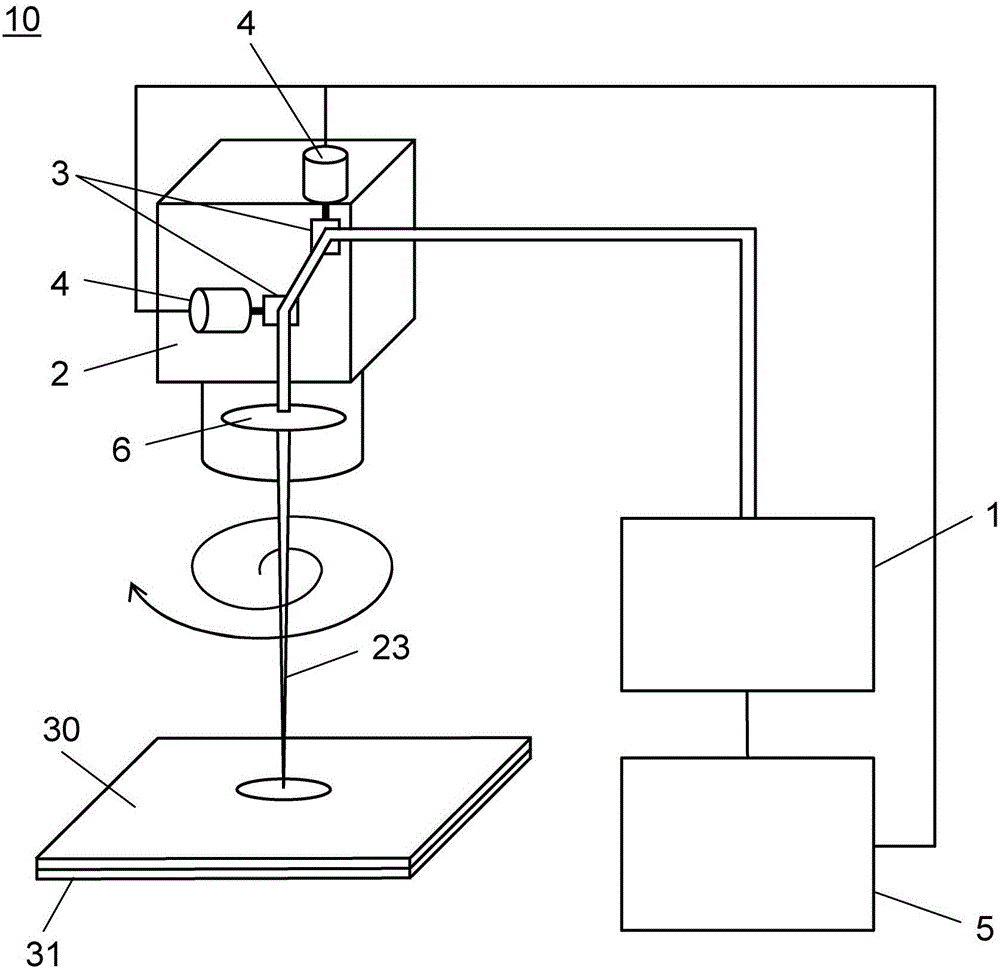

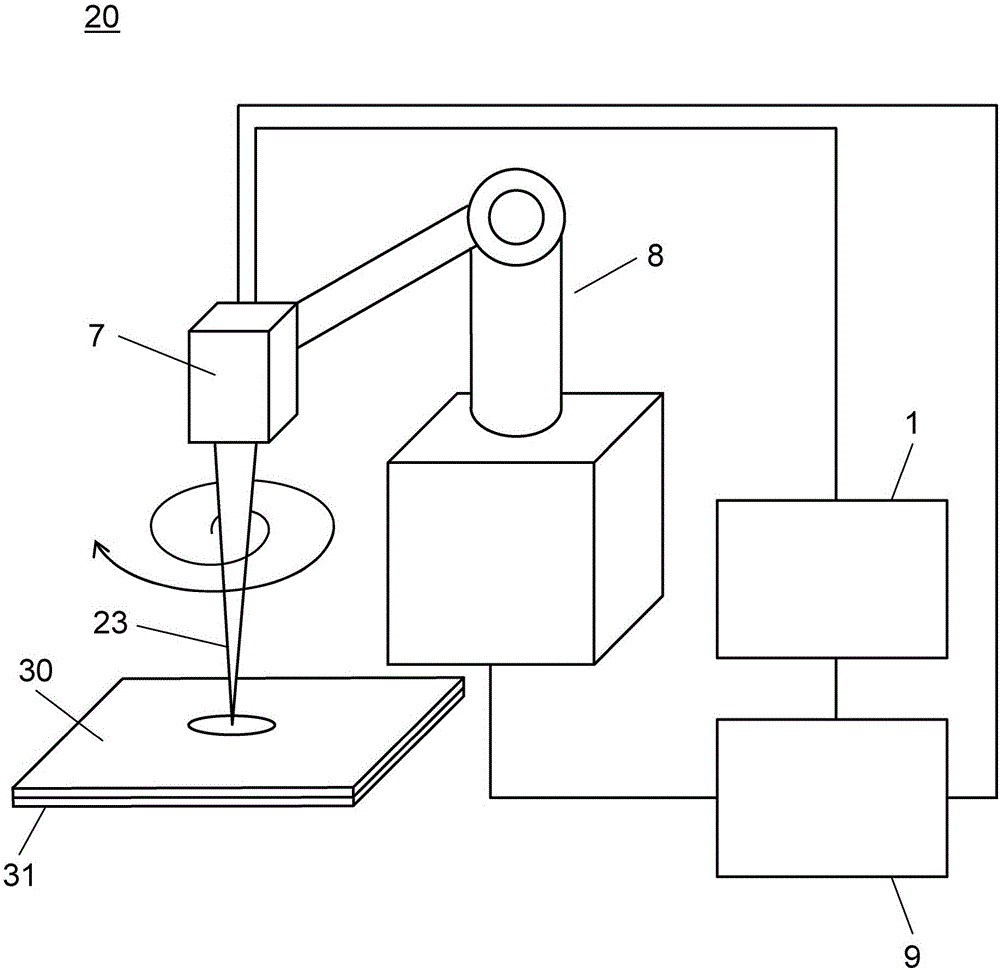

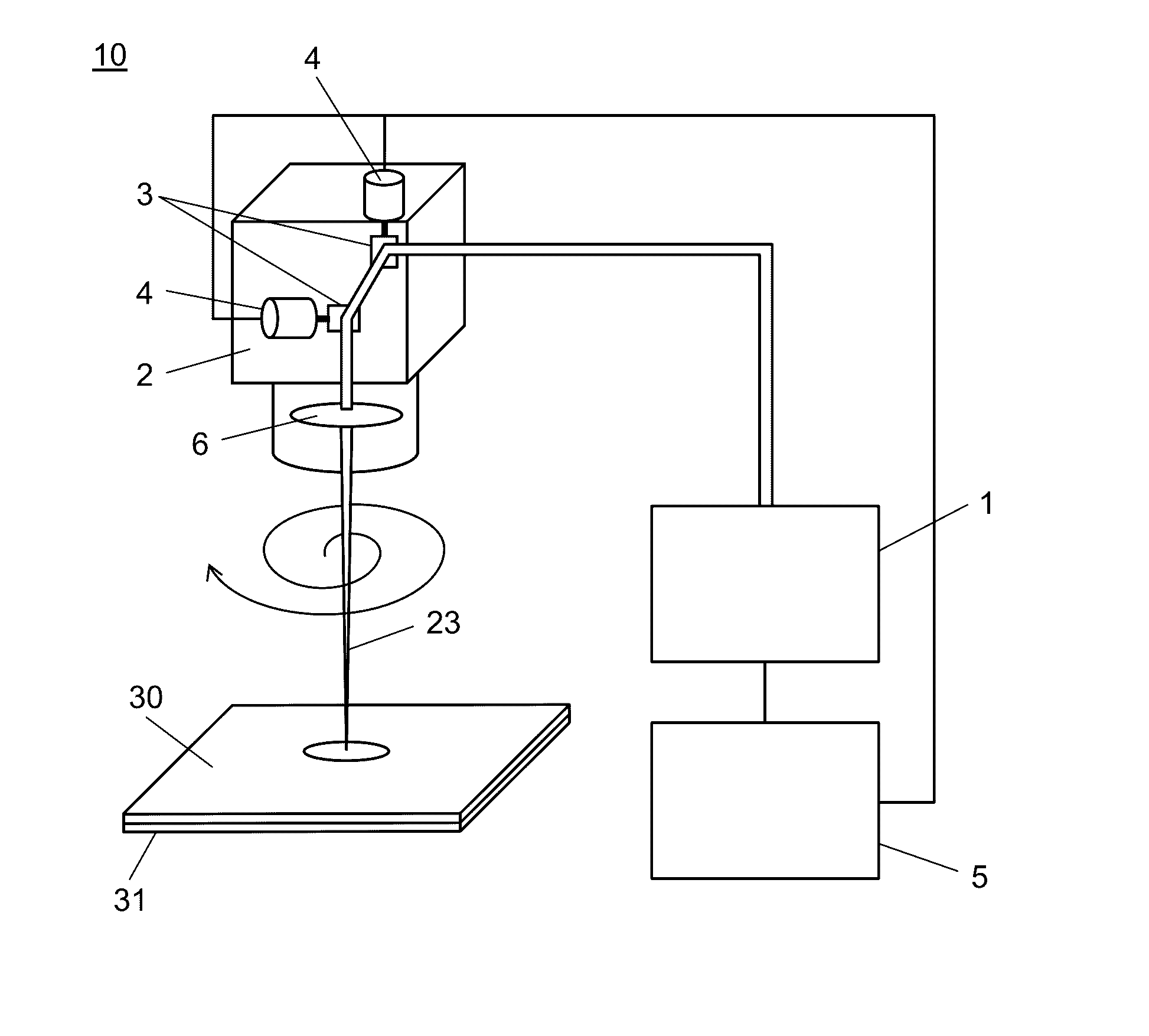

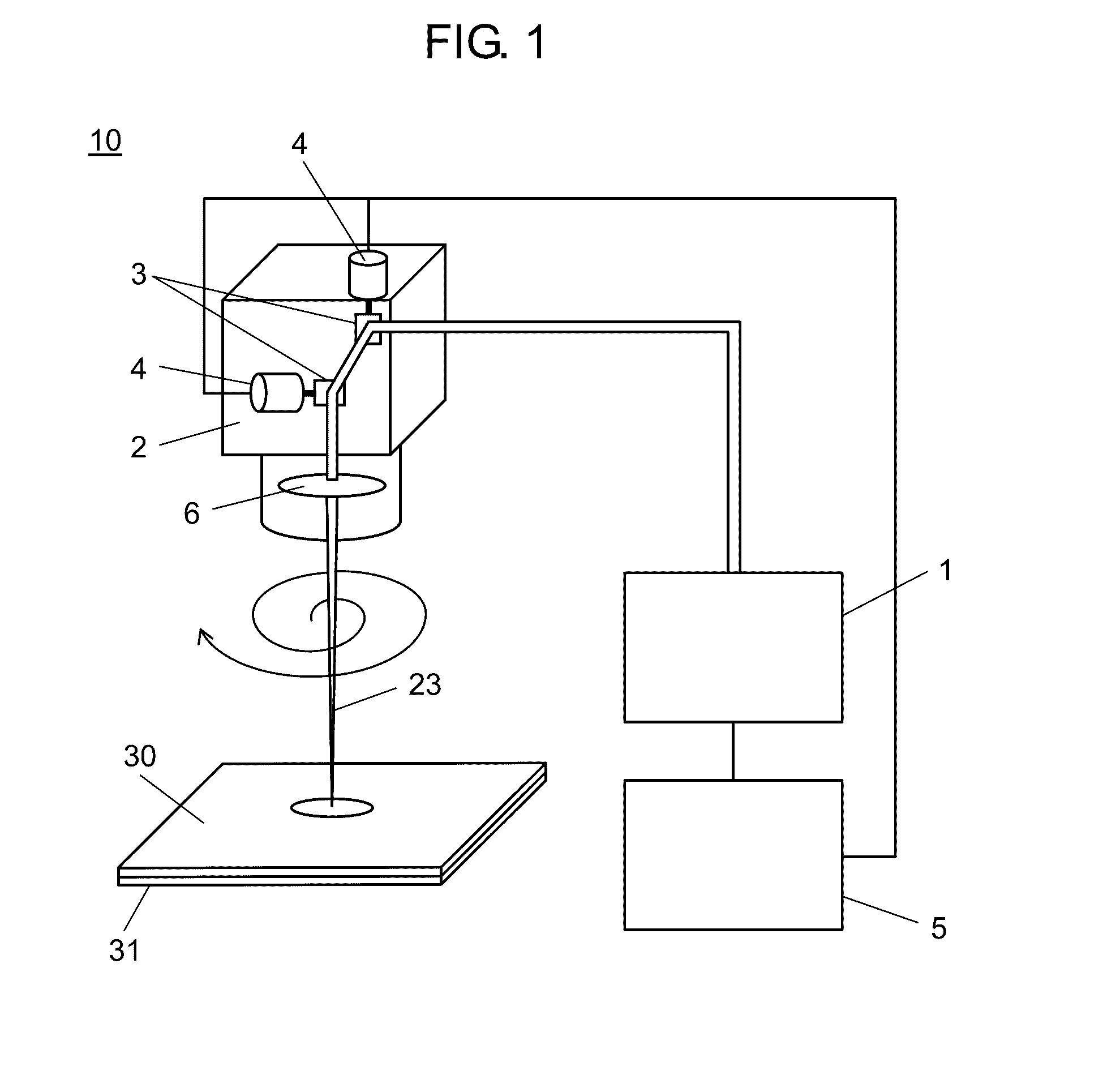

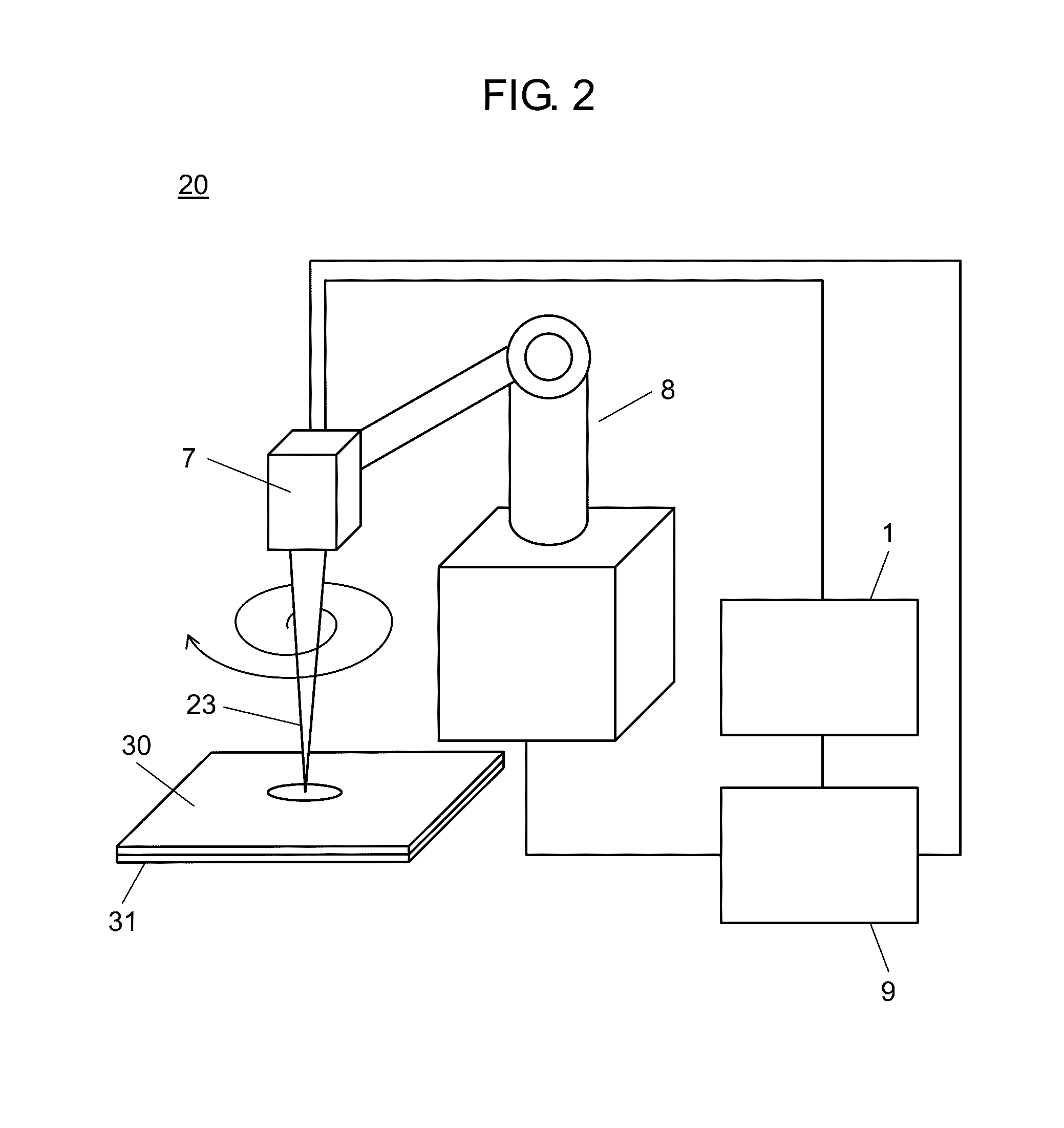

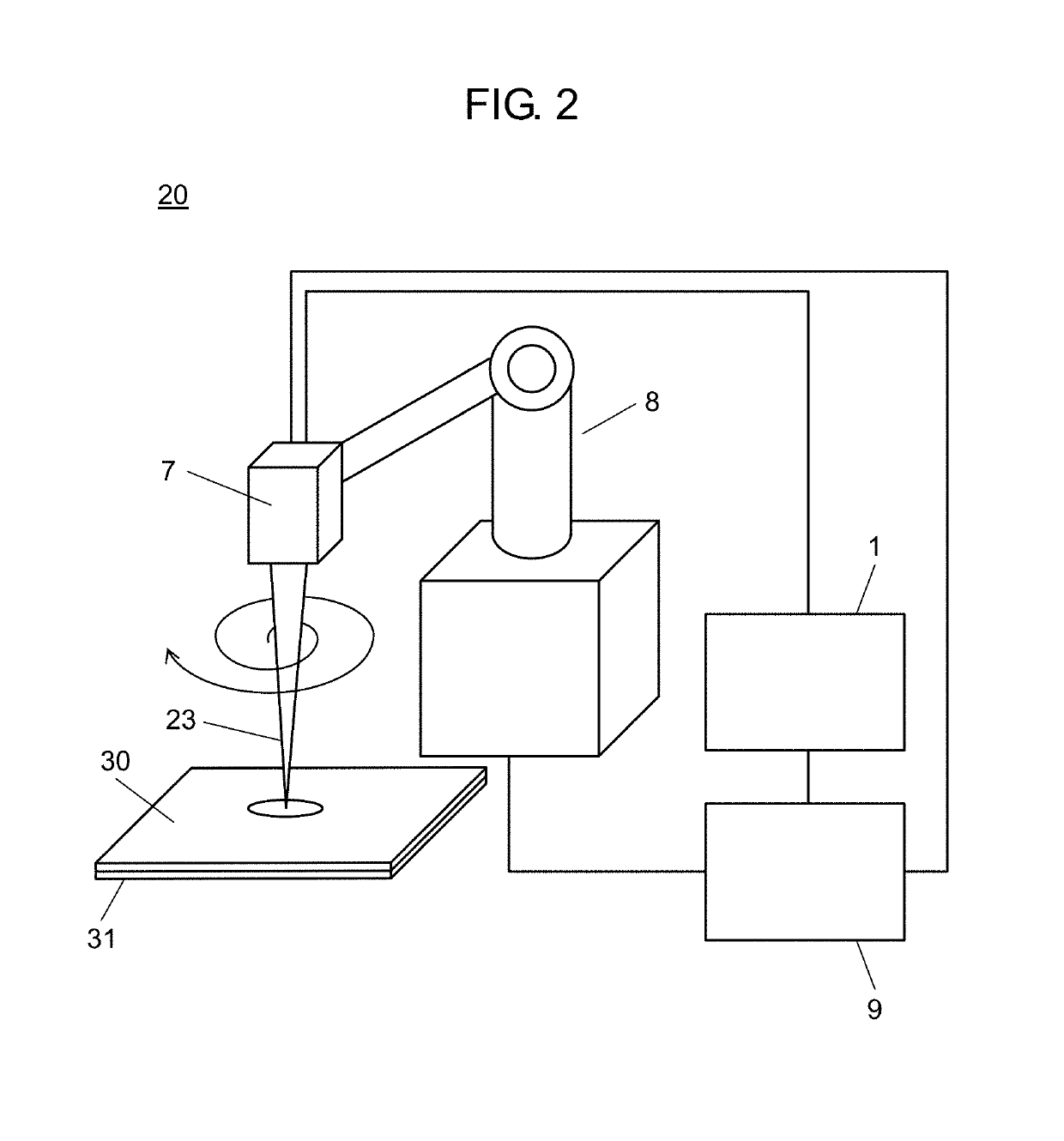

Laser welding method

ActiveCN106029291AInhibitionGood welding conditionLaser beam welding apparatusOptoelectronicsLaser light

This laser welding method has a first step and a second step. In the first step, a first workpiece and a second workpiece are overlaid in a first work area. In the second step, the first workpiece and the second workpiece are irradiated with a laser light in the first work area while the laser light is moved in a spiral path. Also in the second step, the first workpiece and the second workpiece are melted by irradiation of the laser light to form a liquid-phase portion. Also in the second step, the laser light is moved so as not to irradiate the liquid-phase portion a second time.

Owner:PANASONIC INTPROP MANAGEMENT CO LTD

Laser welding method

ActiveUS20170050269A1Good welding conditionSuppress generationLaser beam welding apparatusOptoelectronicsIrradiation

A laser welding method of the present disclosure has a first step and a second step. In the first step, a first workpiece and a second workpiece are overlaid in a first machining region. In the second step, the first workpiece and the second workpiece are irradiated with laser beam in the first machining region while the laser beam is moved in a spiral path. Moreover, in the second step, the first workpiece and the second workpiece are melted by irradiation of the laser beam to form a liquid phase portion. Furthermore, in the second step, the laser beam is moved so that the liquid phase portion is not irradiated with the laser beam again.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

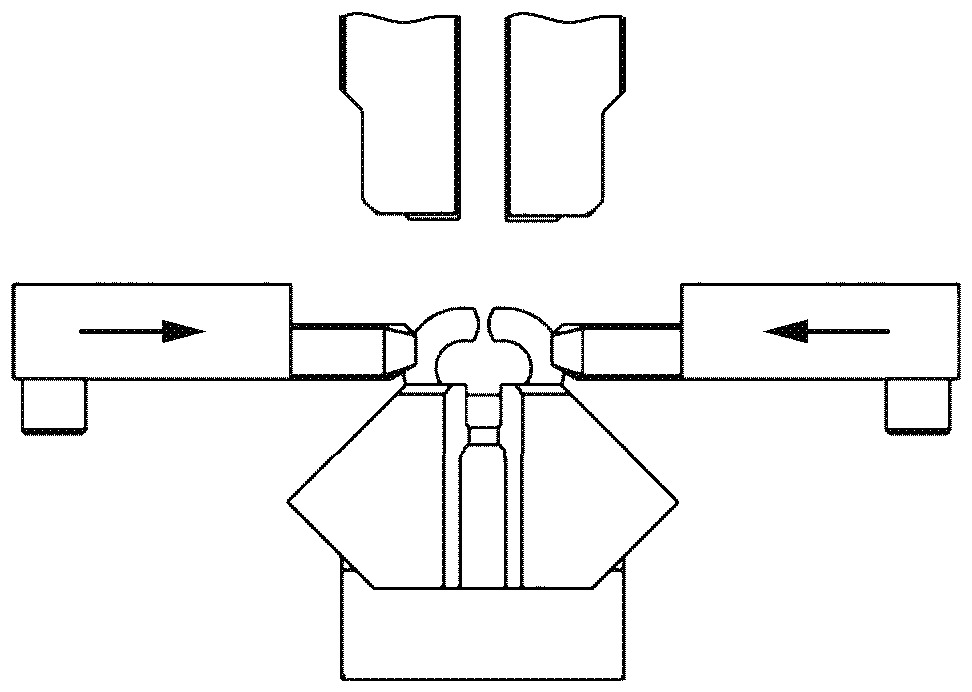

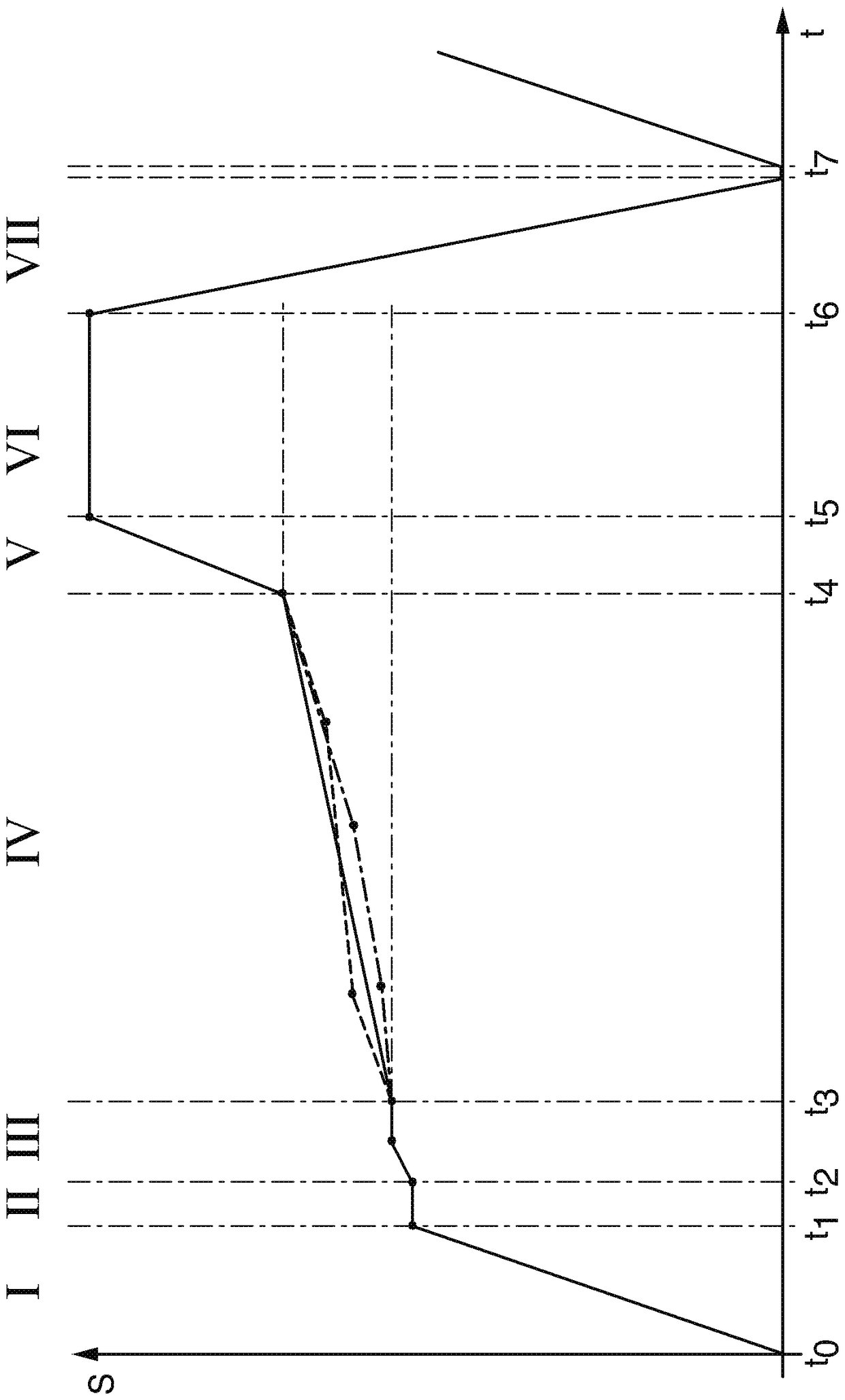

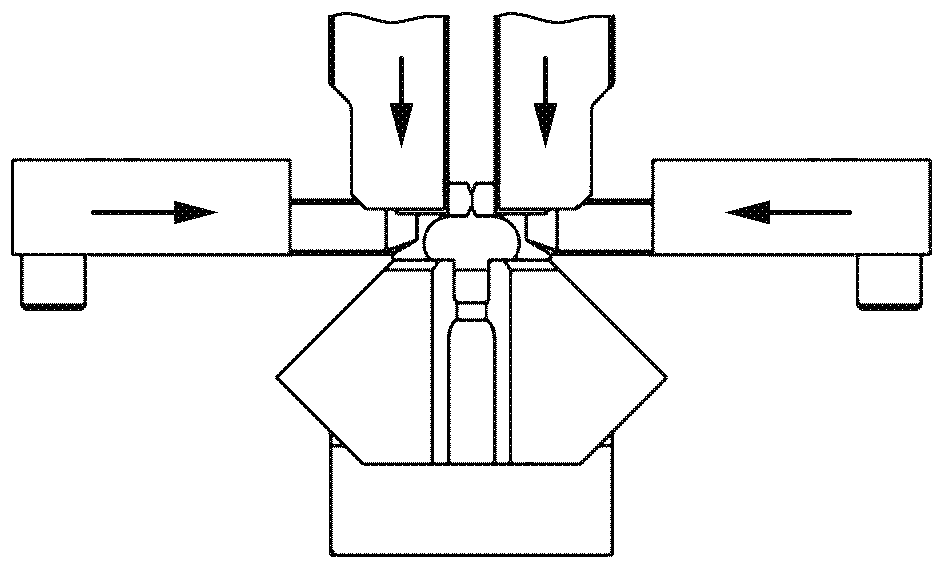

Chain welding machine used for butt welding of chain link resistors

ActiveCN108176918AShort timeGood pier forging processResistance electrode holdersWelding/cutting auxillary devicesPower flowButt welding

The present invention relates to a chain welding machine used for the butt welding of the chain link resistors with the help of the extrusion butting welding. The chain welding machine has a rack, a control shaft used for controlling the motion function of the chain welding machine in time, a chain conveying device used for conveying the chain links that are not welded to the welding positions andexporting the welded chain links from the welding position after the welding operation, an electrode assembly having at least one pair of electrodes that can be provided to the to-be-welded chain link end parts and used for conveying a welding current and two block forging steel racks supporting movably, wherein the block forging steel racks are arranged at the relative sides of the welding positions and are used for bearing the block forging steels used for transmitting the block forging forces and the block forging paths to the chain links at the sides facing each other. A block forging system acting on the block forging steel racks and used for providing the block forging forces and the block forging paths according to the specified block forging progress is designed to programme a block forging curve irrelevant with the control shaft by utilizing the definable correlation between the block forging paths and a time progress and can be programmed freely.

Owner:WAFIOS AKTIENGES

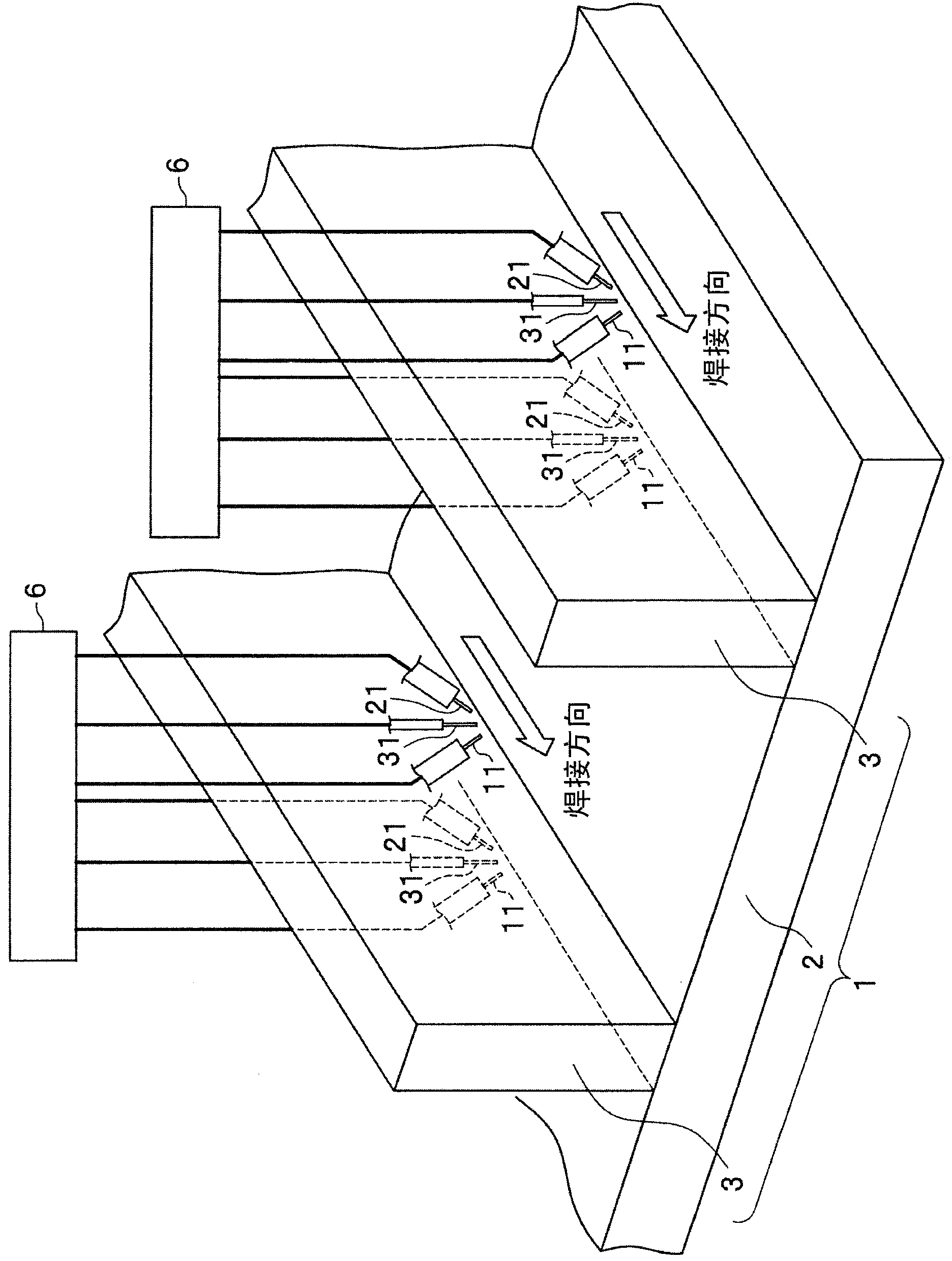

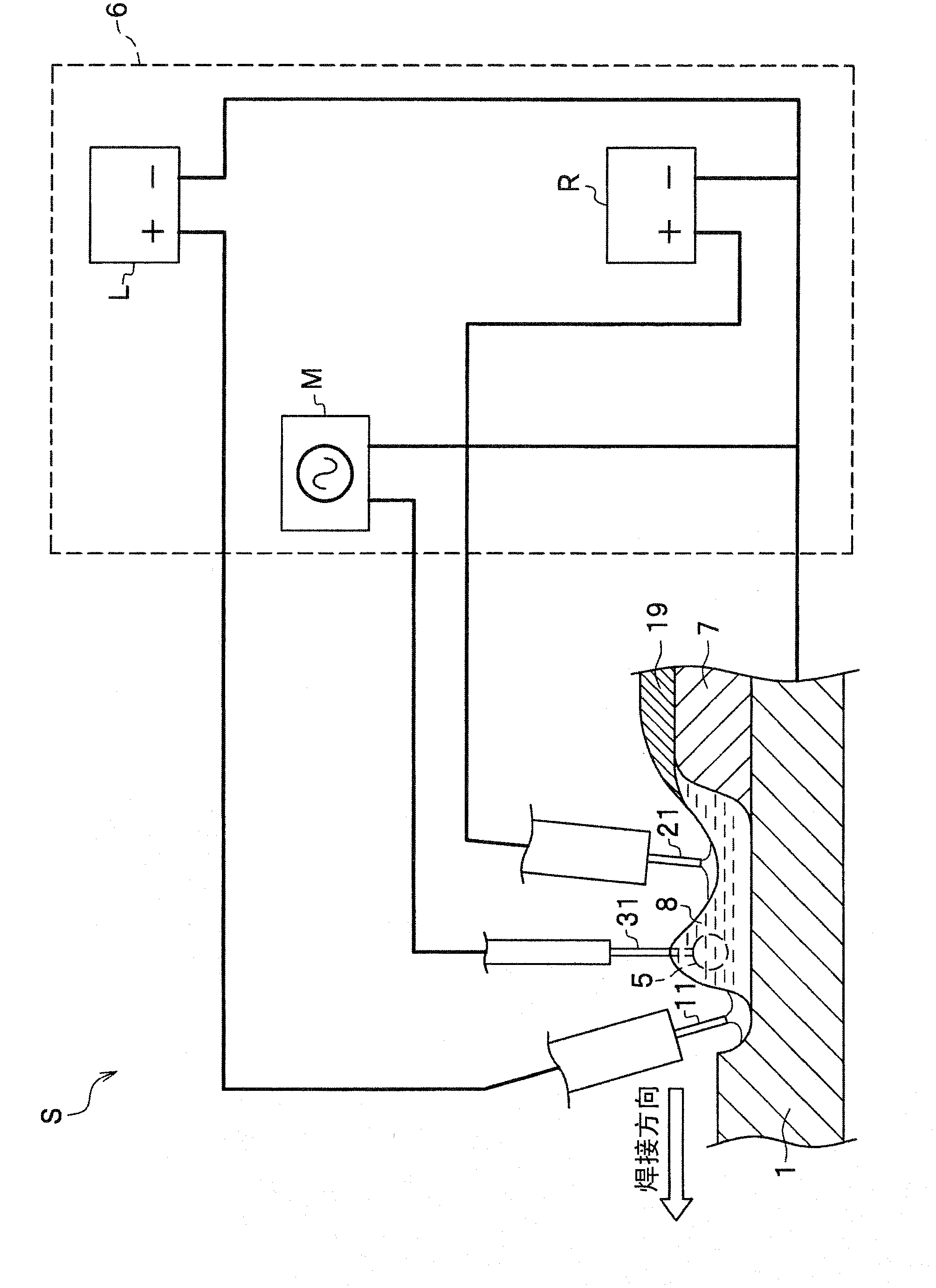

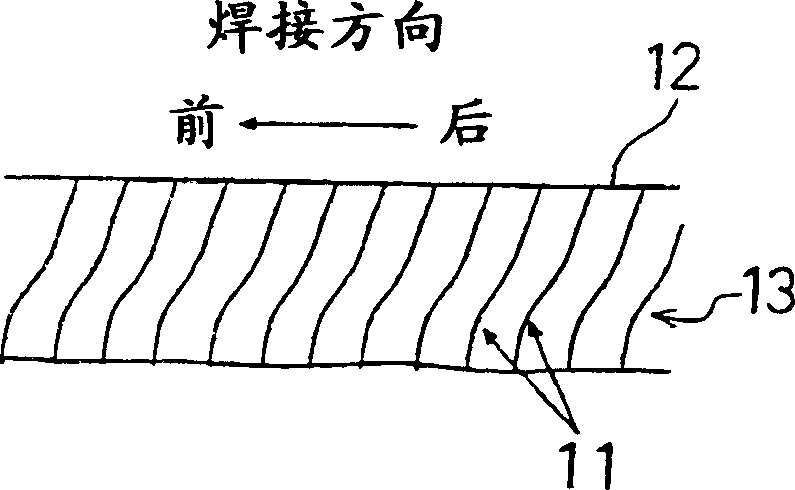

Multielectrode gas-shield arc welding method and device

The invention provides a multielectrode gas-shield arc welding method and a multielectrode gas-shield arc welding device. A welding pass can be good in appearance, the shape of the welding pass is prevented from deforming and the stability of a fusing metal accummulating portion can be achieved even if high-efficiency welding by three electrodes is performed. The multielectrode gas-shield arc welding method is a method using the multielectrode gas-shield arc welding device (S) which comprises a first electrode (11), a follow-up electrode (21) and a central electrode (31) between the first electrode (11) and the follow-up electrode (21). The multielectrode gas-shield arc welding methos is characterized in that the distance between the first electrode (11) and the follow-up electrode (21) is set to be 15mm to 50mm, direct currents with reversed polarities flow across the first electrode (11) and the follow-up electrode (21), and alternate currents with the fixed current characteristics or decreasing characteristics are made to flow across the central electrode (31) for welding.

Owner:KOBE STEEL LTD

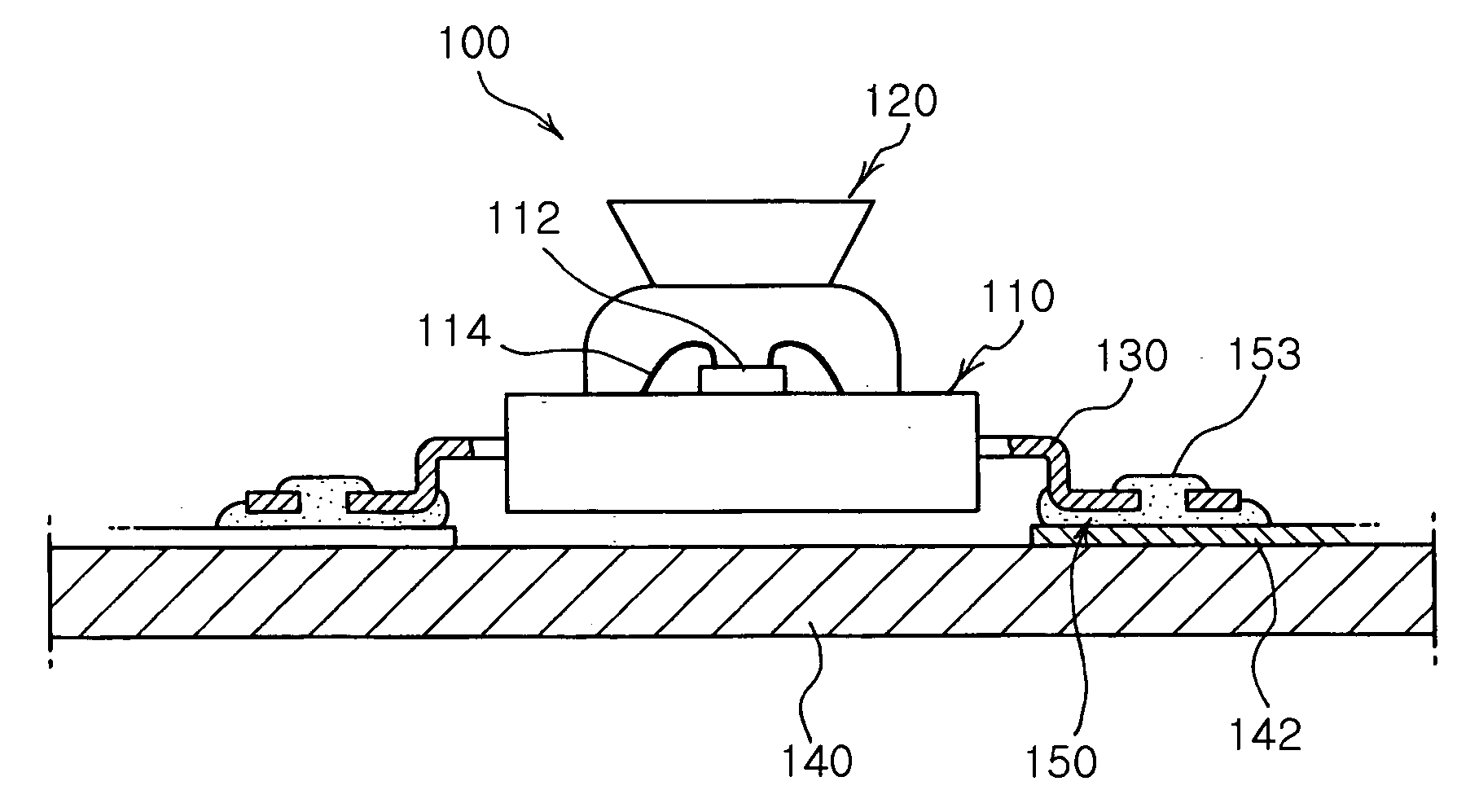

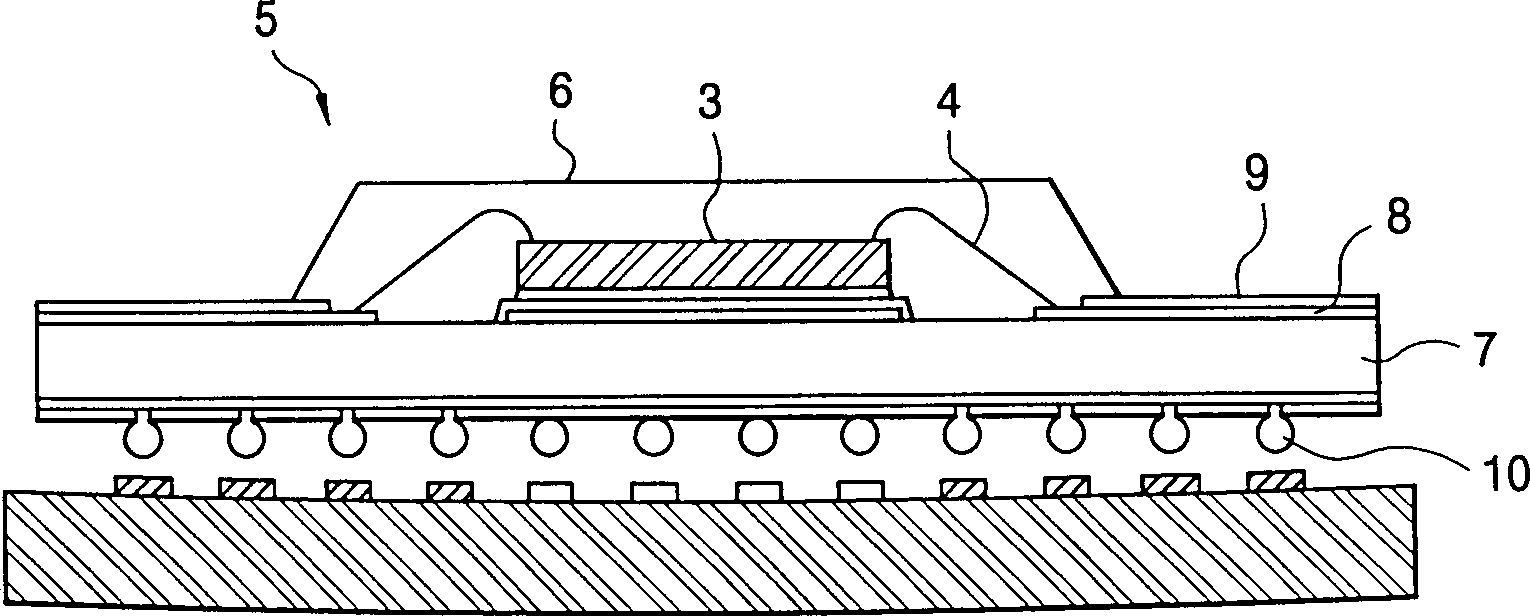

LED having improved soldering structure, method for soldering the LED to PCB, and LED assembly manufactured by the method

InactiveUS20070029572A1Good welding conditionSave amountFinal product manufacturePrinted circuit aspectsEngineeringSolder paste

The invention relates to an LED with an improved soldering structure, a method of assembling the LED to a PCB, and an LED assembly manufactured by the method. The LED includes an LED chip and a pair of leads with an end electrically connected the LED chip and the other end to be connected to an external power source, having a hole or a cutout part formed therein. The LED also includes a package body housing a part of the lead in the side of the LED chip, and a transparent lens placed on a surface of the package body in the side of the LED chip, for emitting light laterally. This improves soldering conditions for soldering with the other end of the lead placed on the solder, saving the amount of a solder paste while enhancing bonding strength after soldering.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

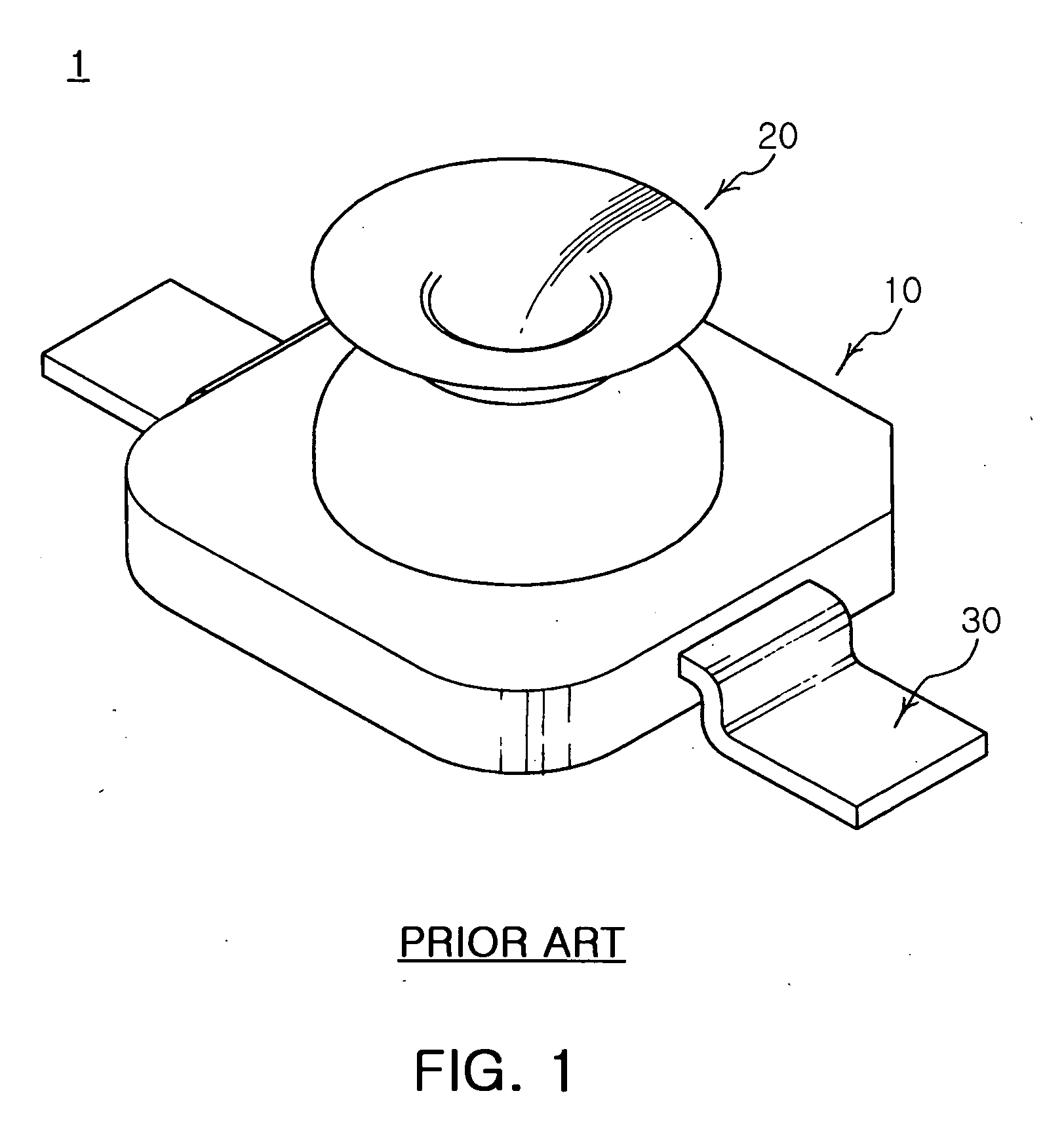

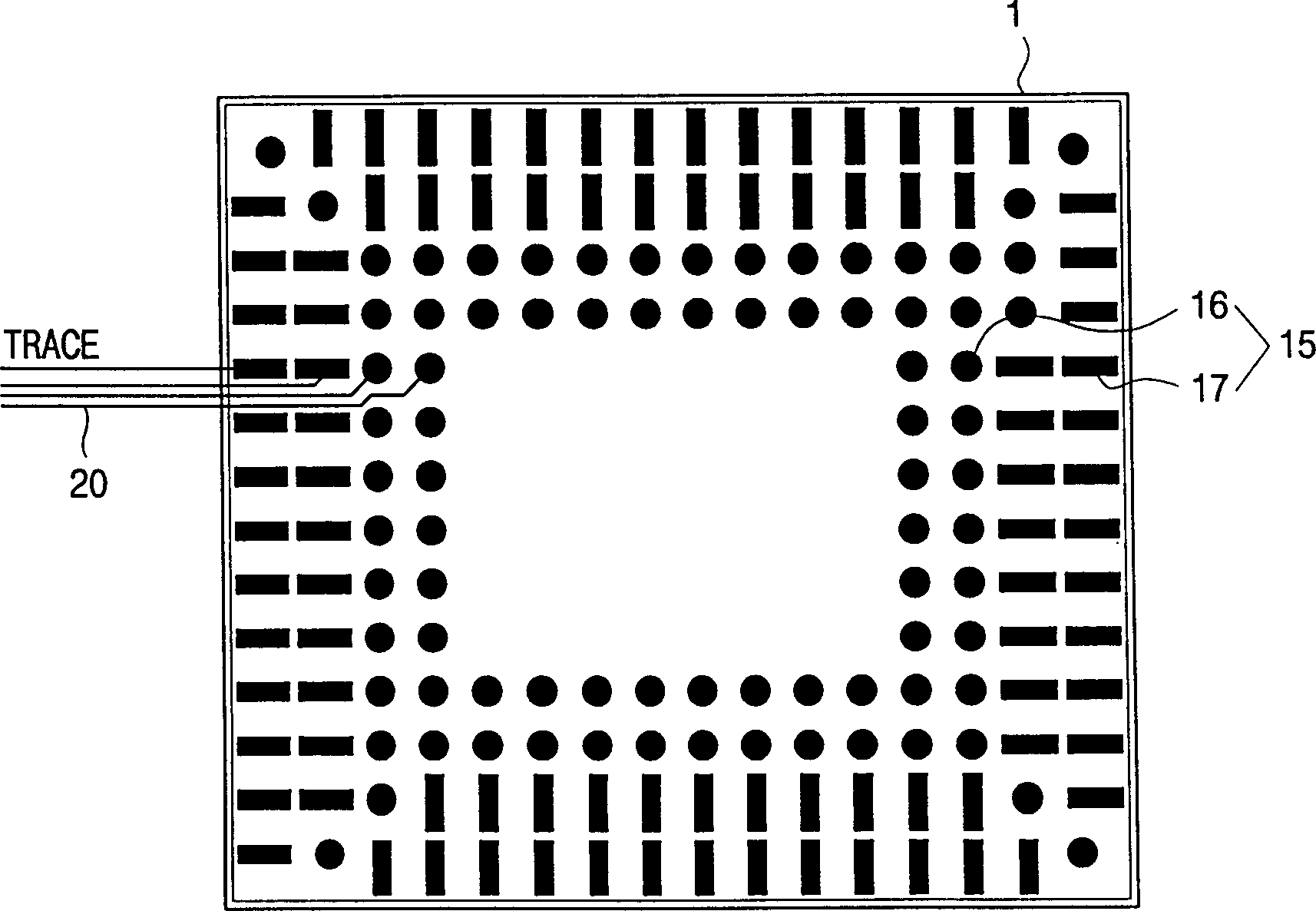

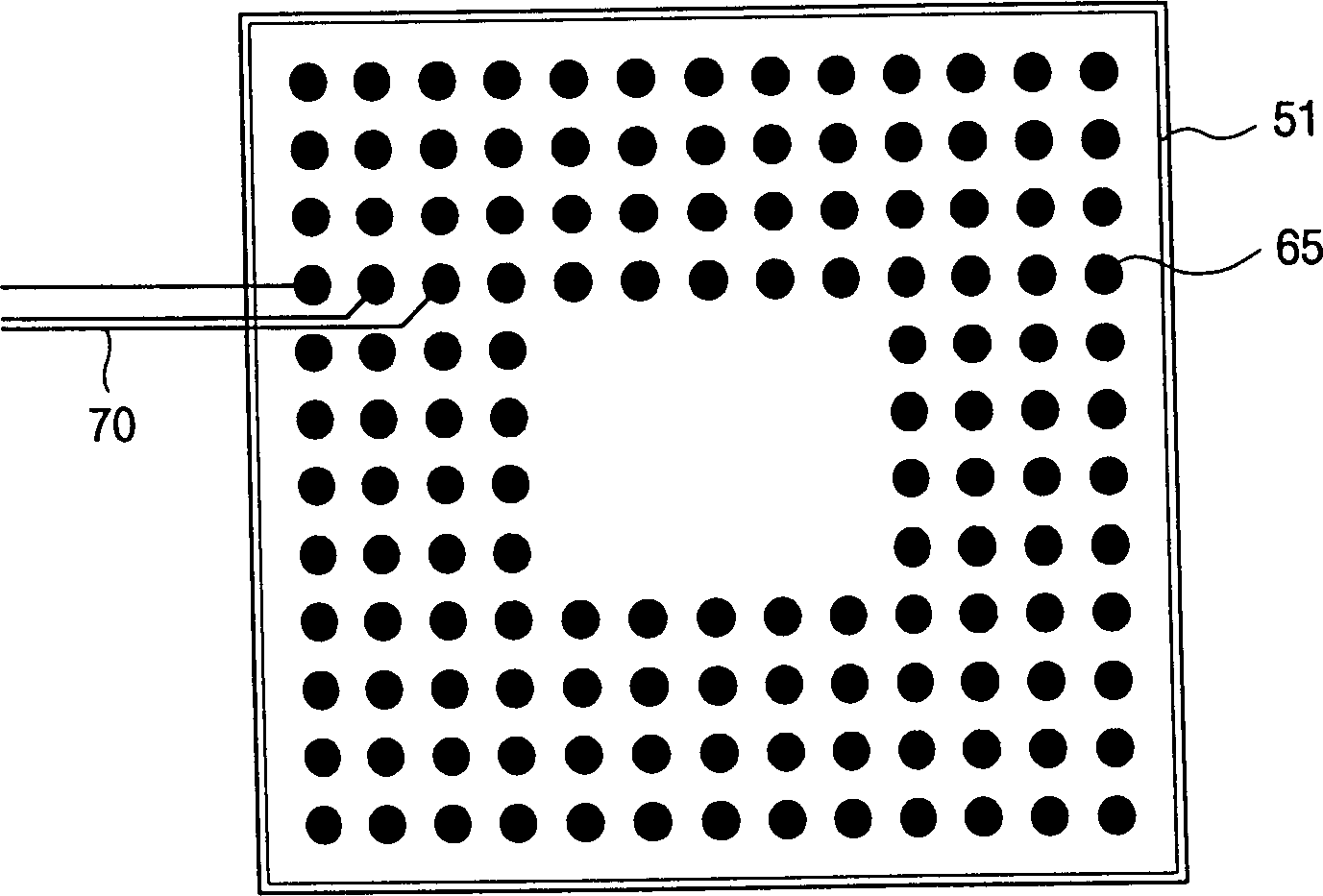

Printed circuit board with improved pad structure

InactiveCN1396799ASimple designIncrease the number ofPrinted circuit assemblingFinal product manufactureSemiconductor packageSemiconductor chip

A printed circuit board (PCB) having a plurality of lands corresponding to a plurality of solder pins provided on a semiconductor chip package, the lands provided adjacent to the border of the printed circuit board having a rectangular shape elongated in a direction toward the border, thus providing a printed circuit board which can achieve a simple design, improve the integration of peripheral chips mounted thereon, and secure a fine soldering state.

Owner:SAMSUNG ELECTRONICS CO LTD

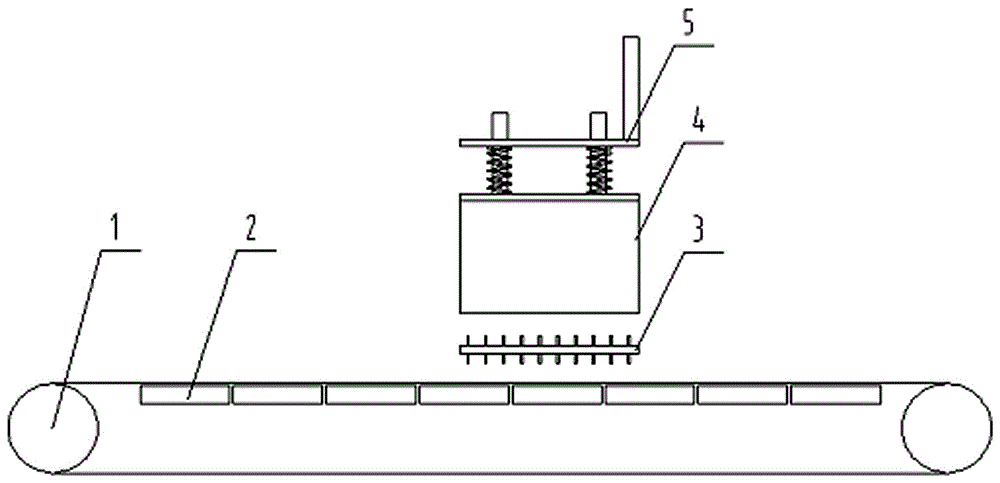

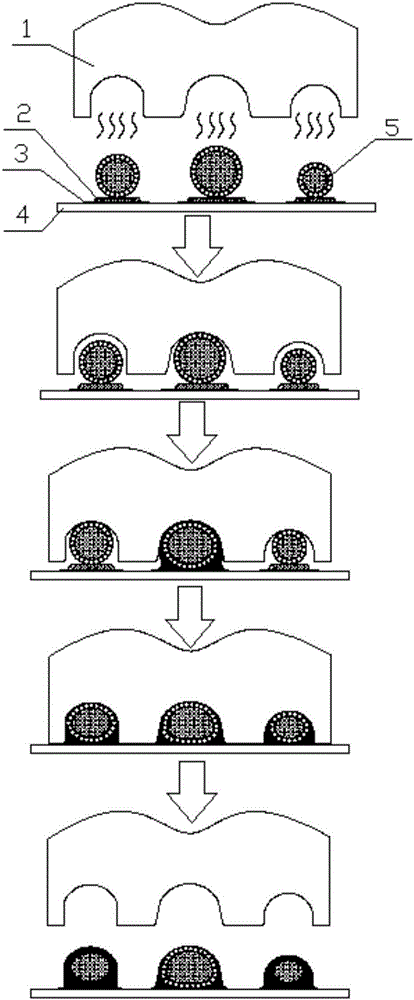

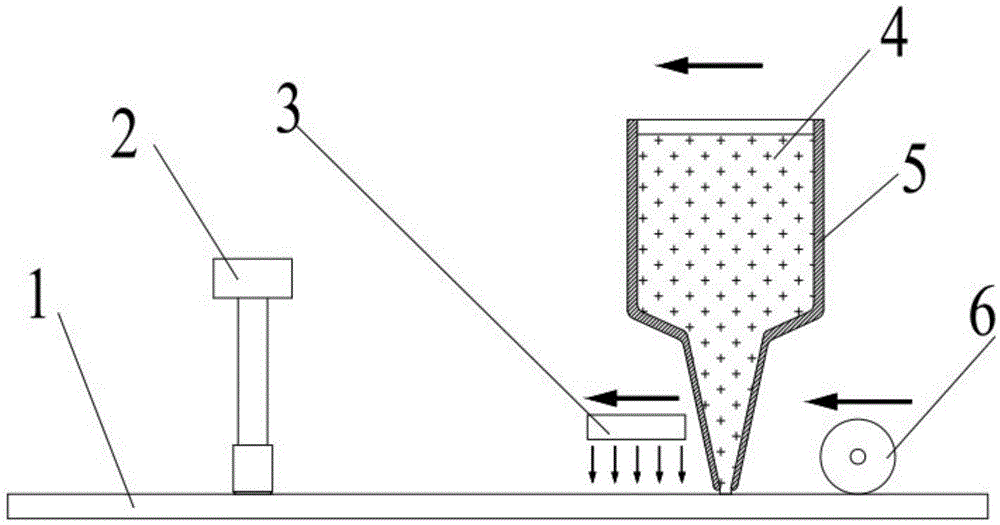

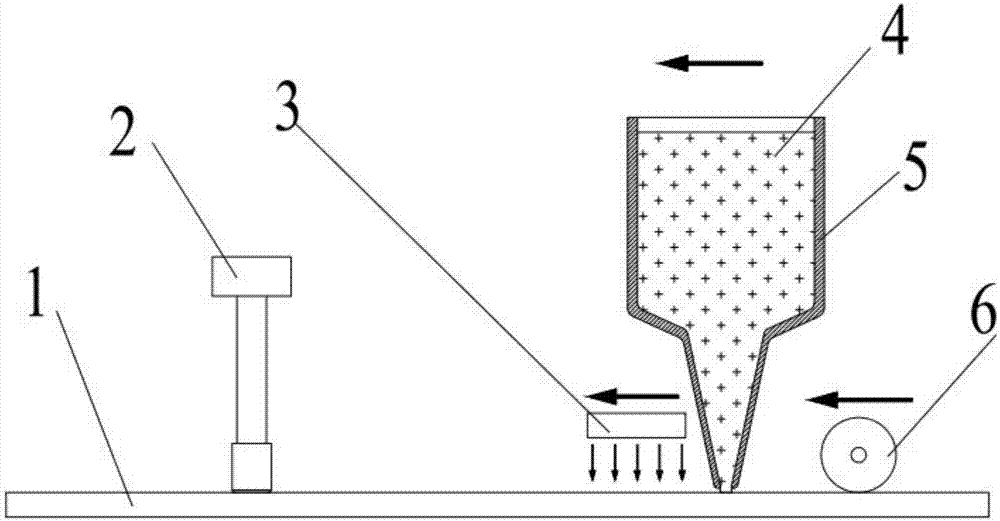

Infrared welding device for solar battery string

InactiveCN106001828AGood welding conditionFix compatibility issuesHeating appliancesMetal working apparatusTemperature controlEngineering

The invention discloses an infrared welding device for a solar battery string. The infrared welding device for the solar battery string comprises a conveying mechanism, a heating platform, laid battery pieces and laid solder strips. A welding head lifting mechanism is installed on the corresponding upper portion of the conveying mechanism and provided with an infrared welding head. A lifting pressing pin mechanism is arranged on the lower portion of the infrared welding head. A vacuum negative pressure adsorption mechanism is arranged between the conveying mechanism and the heating platform. In this way, the battery pieces and the solder strips are laid on the conveying mechanism with the heating platform and conveyed to the welding position under the infrared welding head, and it is guaranteed that the pressing pin mechanism makes reliable contact with the solder strips and the battery pieces when pressed downwards. In addition, the welding head is located at the best welding distance through adjustment of the lifting mechanism, and then the battery string is conveyed to the next station through the conveying mechanism after being welded with the infrared welding head. Meanwhile, the heating platform further plays the function of slow cooling through temperature control over different parts, and the breaking rate in the welding process is effectively lowered.

Owner:HEBEI YIHENG SCI & TECH CO LTD

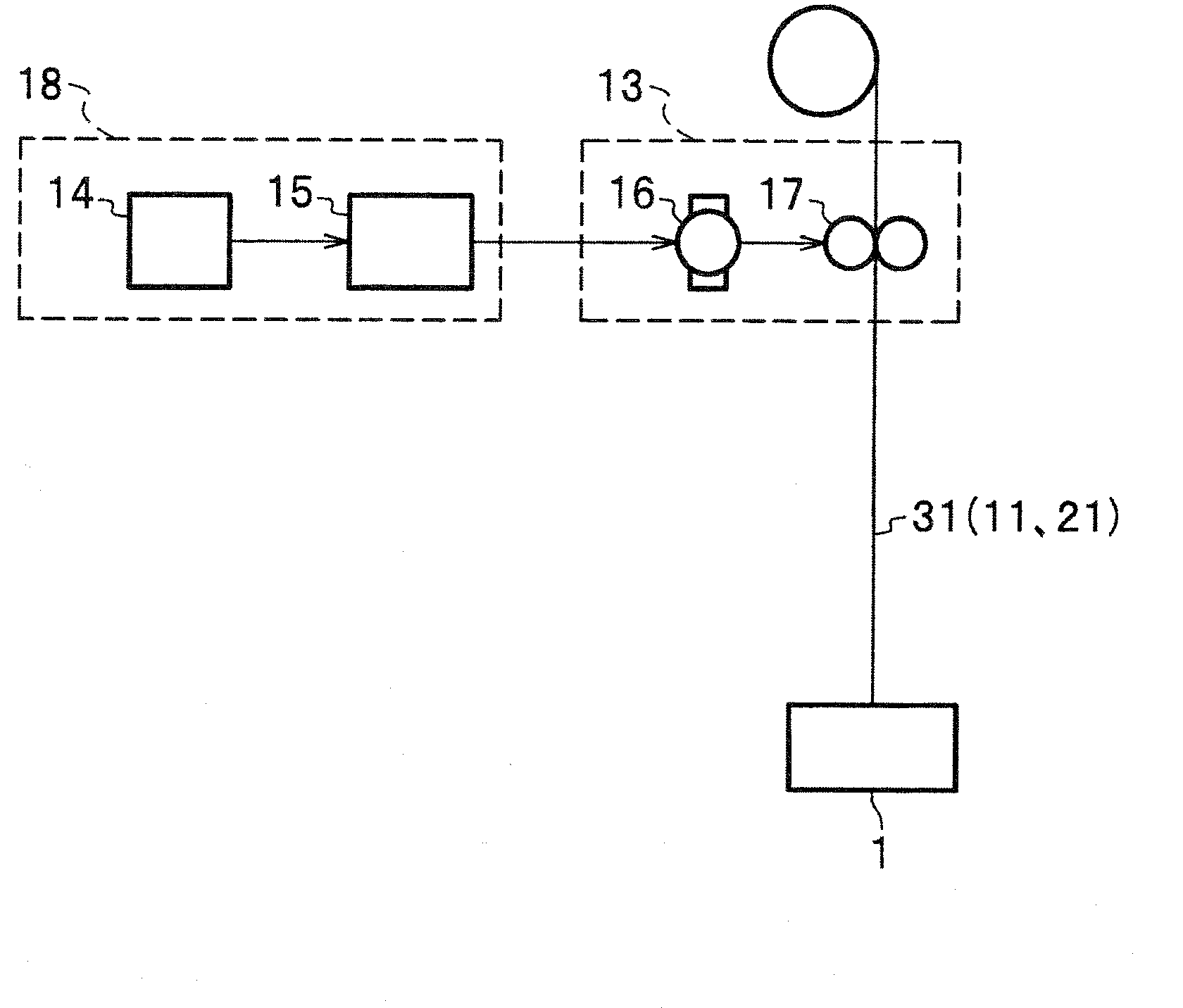

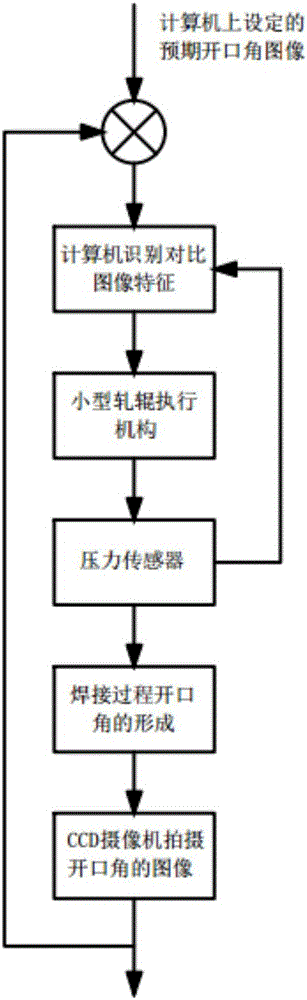

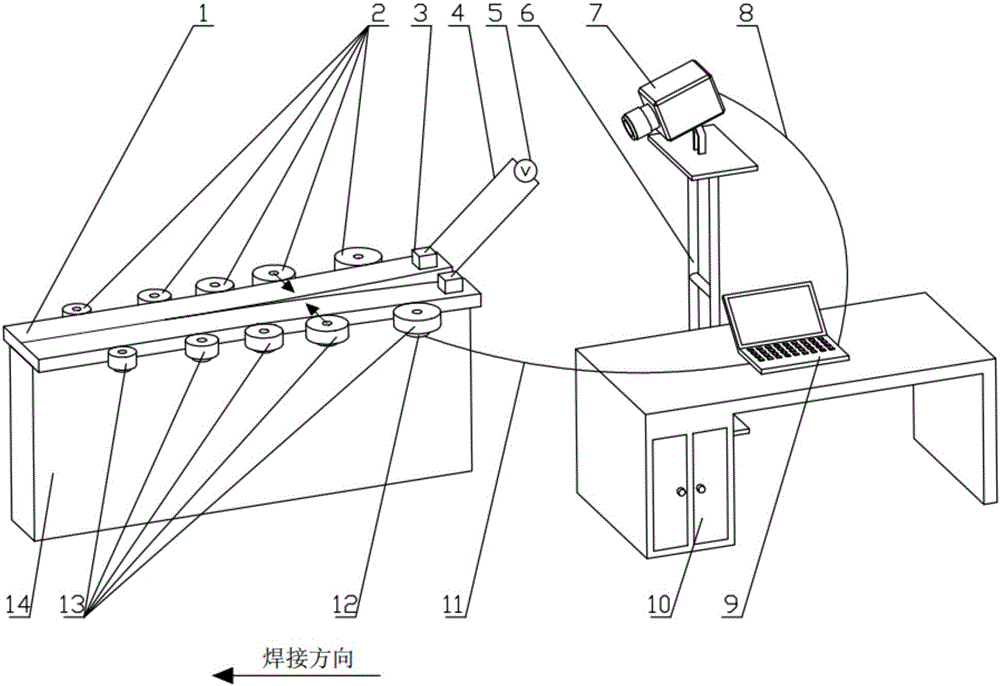

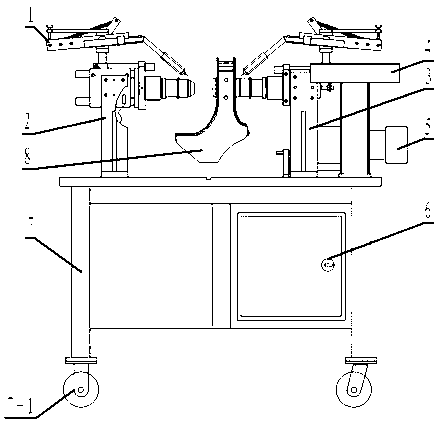

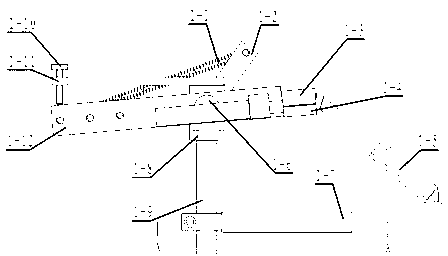

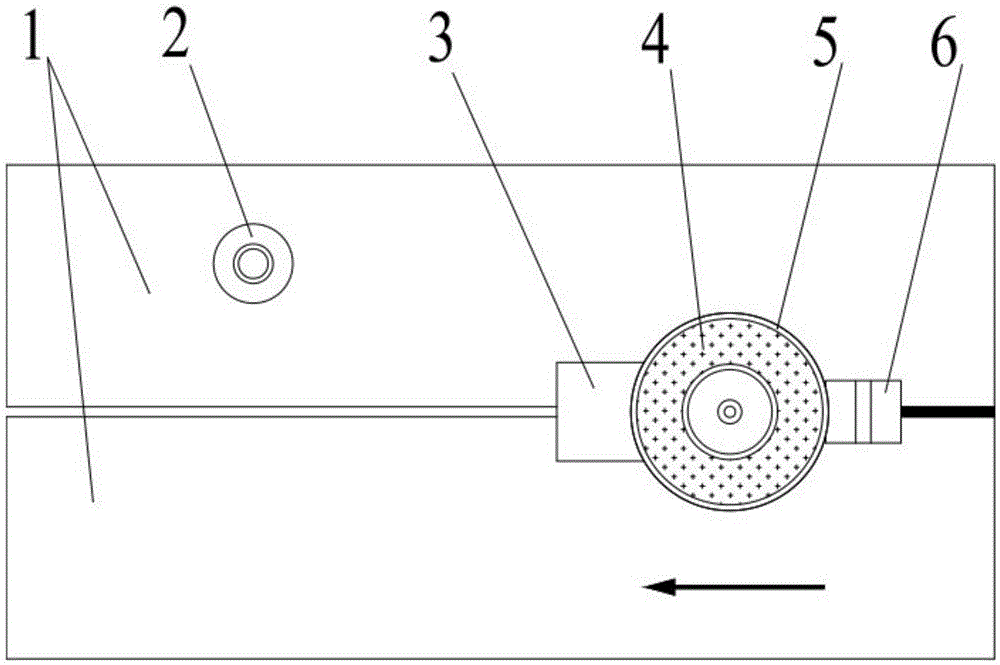

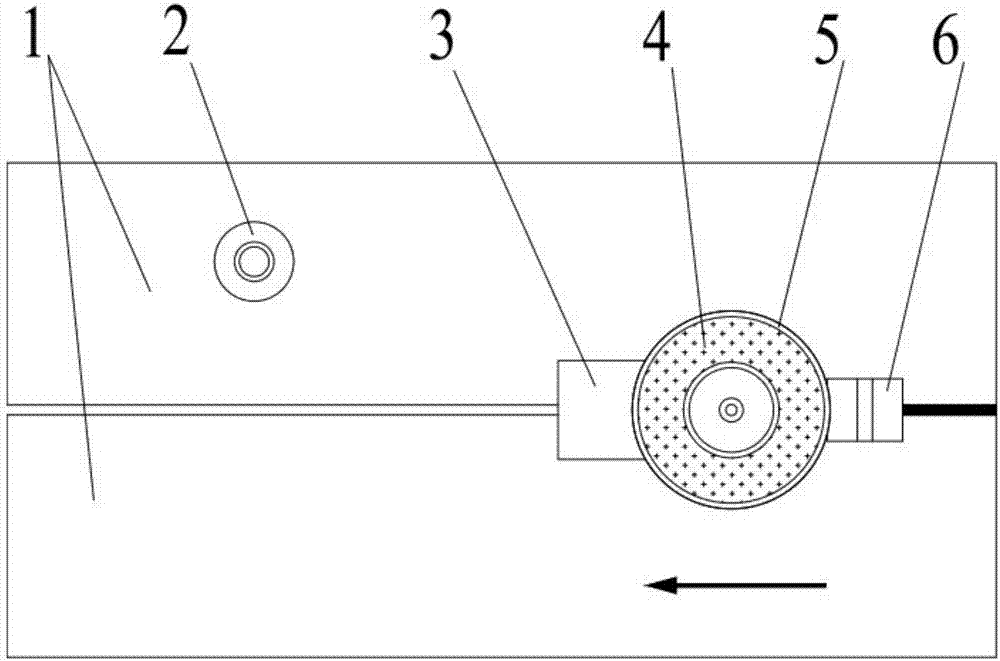

Experimental device for flexible closed-loop control over ERW pipe weld joint opening angles

InactiveCN105904075AQuality improvementGood welding conditionWelding monitoring devicesMetal working apparatusEngineeringWorkbench

The invention discloses an experimental device for flexible closed-loop control over ERW pipe weld joint opening angles. The device comprises a high-frequency generator, an output device of the high-frequency generator, a CCD vidicon, a computer and five pairs of small rollers. Two electrode contacts are symmetrically fixed to a pipe blank located on a workbench with a weld joint as the center line, high-frequency currents form a circuit through the two electrode contacts and the pipe blank, the five pairs of small rollers are arranged in the manner that the appearance dimensions are gradually reduced in proportion and are sequentially in contact with the positions, at the two sides of the center line of the weld joint, of the surface of the pipe blank, and a pressure senor is mounted in a base below each small roller. The pressing amount of each pair of small rollers is changed by changing the axial distance and the radial distance between the pair of small rollers to obtain the opening angles different in size and shape. A closed-loop system is formed by the CCD vidicon, the computer and the pressure sensors, the precision of the sizes and shapes of the opening angles is guaranteed, optimal welding conditions can be obtained by carrying out experimental analysis on the sizes and shapes of the opening angles, and the quality of a welded pipe can be improved.

Owner:江苏金诺炉辊有限公司

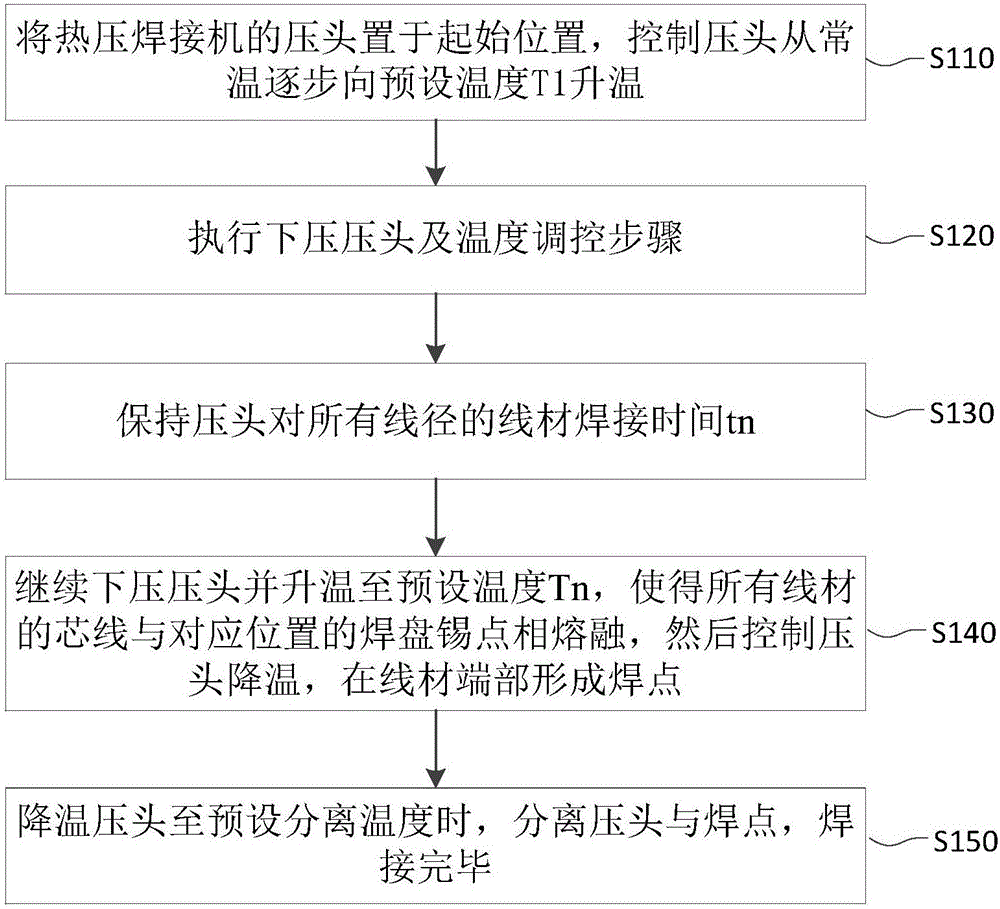

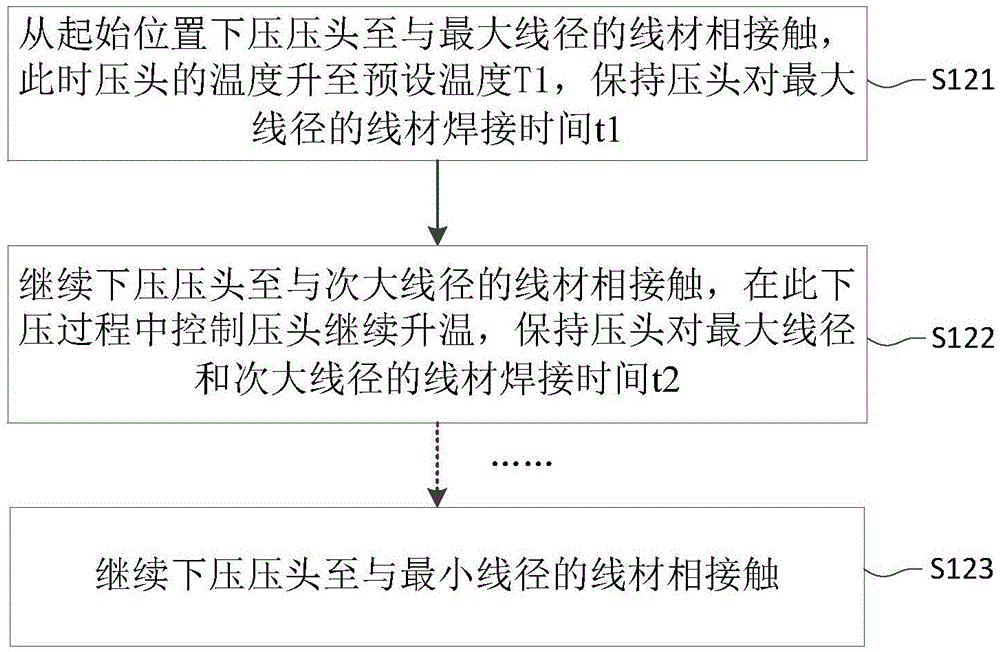

Thermal compression welding method

ActiveCN106392295AGood welding conditionGuaranteed to melt completelyNon-electric welding apparatusThermal compressionEngineering

The invention provides a thermal compression welding method. A thermal compression welding machine is utilized to weld at least two wire rods in different wire diameters at the same time. The thermal compression welding method includes the steps that a pressing head of the thermal compression welding machine is placed at the starting position, and the temperature of the pressing head is controlled to gradually rise to the preset temperature T1 from the normal temperature; the steps of downwards pressing the pressing head and adjusting and controlling the temperature are repeatedly executed till the pressing head makes contact with the wire rod in the minimum wire diameter, and the welding time of the pressing head on the wire rods in all wire diameters is kept tn; the pressing head continues to be pressed downwards and the temperature of the pressing head rises to the preset temperature Tn, core wires of all the wire rods and tin points of bonding pads at the corresponding positions are made to be fused, then the temperature of the pressing head is controlled to be lowered, and welding points are formed on the end portions of the wire rods; and when the temperature of the pressing head is lowered to the preset separation temperature, the pressing head and the welding points are separated, and welding ends. By means of the thermal compression welding method, soft wire rods in various wire diameters can be sequentially fused till welding is completed, the welding speed is high, and the welding quality is high.

Owner:GOERTEK INC

Automatic welding equipment for double annular welding beads

ActiveCN103008940AFulfill welding requirementsRealize continuous weldingWelding/cutting auxillary devicesAuxillary welding devicesAutomatic test equipmentCaster

An automatic welding equipment for double annular welding beads is used for solving problems of high equipment cost, low manual welding efficiency and hardly guaranteed welding quality of a welding robot. The automatic welding equipment comprises a welding gun position switching and welding gun clamping adjusting mechanism, a left side positioning mechanism, a right side positioning mechanism, an operation station, a power output mechanism, a control mechanism and a base stage, wherein the welding gun position switching and welding gun clamping adjusting mechanism comprises a left part and a right part, which are symmetric and respectively mounted together with the left side positioning mechanism and the right side positioning mechanism; the left side positioning mechanism, the right side positioning mechanism and the operation station are all fixed on the base stage; the power output mechanism is mounted together with the right side positioning mechanism; and a caster is arranged at the bottom of the base stage. The automatic welding equipment has the advantages of simple operation, convenient maintenance and low manufacturing cost; the welding efficiency can be increased, the product quality is improved, the welding operation condition is improved and the labor intensities of operators are reduced.

Owner:长城汽车股份有限公司平湖分公司

Weldability of aluminum alloys

InactiveUS20140272566A1Improve solderabilityHigh strengthElectrode carriers/collectorsActive material electrodesThin layerSolderability

A method is provided for modifying a surface of a first, relatively difficult-to-weld metal substrate in preparation for a subsequent joining method by applying a thin layer of a second, relatively easy-to-weld metal to the surface of the first metal substrate.

Owner:KYLYVNYK KONSTYANTYN +1

Metal spraying material without lead

InactiveCN101050528AImprove high-frequency test pass rateImprove bonding fastnessMetallic material coating processesWelding/cutting media/materialsSputteringRare earth

This invention discloses a leadless sputtering material for end sputtering of metalized thin film capacitor. The leadless sputtering material comprises: Sn 40-79 wt.%, Sb 0.5-2 wt.%, Cu 0.01-0.5 wt.%, Al 1-15 wt.%, impurities less than or equal to 0.1 wt.%, and Zn as balance. Besides, mixed rare earth metals such as La and Ce 0.01-0.2 wt.%, preferential 0.1-0.15 wt.%, can also be added. The leadless sputtering material can be directly used for end sputtering of metalized thin film capacitor without the need for spraying a base layer first, which can largely simplify the spraying operation. The leadless sputtering material has high compatibility with present spraying apparatus and process.

Owner:戴国水

Ultrasonic-assisted semi-solid welding method

InactiveCN105522246AImprove mechanical propertiesEasy to useSoldering apparatusUltrasonic assistedMegasonic cleaning

The invention discloses an ultrasonic-assisted semi-solid welding method. The ultrasonic-assisted semi-solid welding method includes steps of cleaning base metal by the aid of ultrasonic waves; fusing and cooling welding flux; adding semi-solid into the welding flux in cooling procedures and stirring the semi-solid; cooling the welding flux until the temperature of the welding flux reaches 600-630 DEG C, and then pouring the welding flux into a constant-temperature injecting machine to keep the temperature of the welding flux constant; heating the welding base metal and carrying out ultrasonic-assisted vibration on the welding base metal; opening a discharge outlet of the constant-temperature injecting machine to start to inject the welding flux; shifting an in-situ induction heater and the constant-temperature injecting machine by 20 mm, then applying specific pressures on original positions of welding seams by the aid of rolling pressure heads, keeping the rolling pressure heads to move towards non-welded regions along the welding seams at the speeds identical to the speeds of the in-situ induction heater and the constant-temperature injecting machine, keeping the specific pressures unchanged in moving procedures and ultimately obtaining welded components. The components which are high in mechanical property and good in service performance can be obtained by the aid of the ultrasonic-assisted semi-solid welding method by means of welding, and the ultrasonic-assisted semi-solid welding method has the advantages of wide applicable material ranges, high production efficiency, good welding conditions and the like. Besides, the ultrasonic-assisted semi-solid welding method has great development prospects and application spaces.

Owner:HARBIN INST OF TECH AT WEIHAI

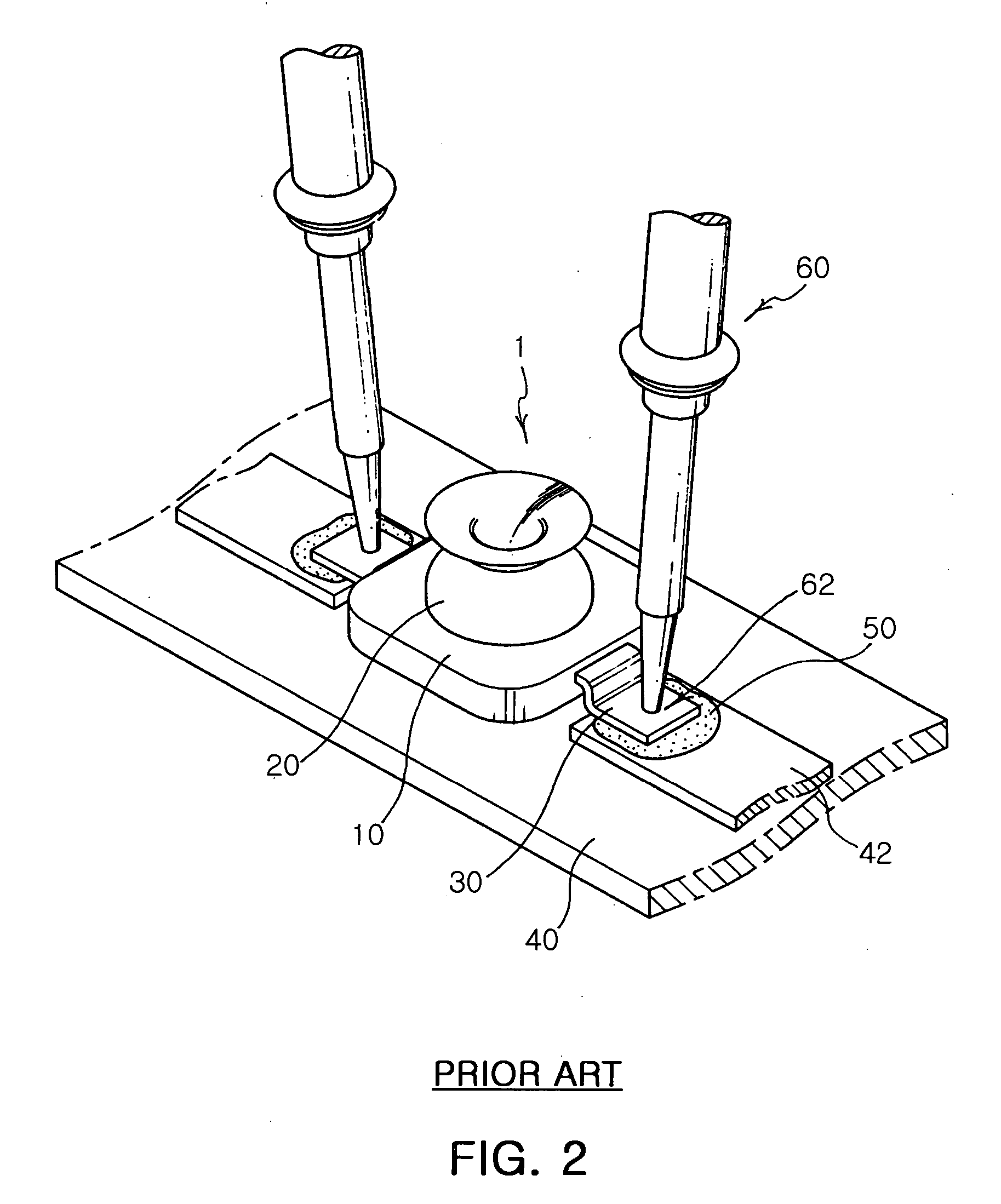

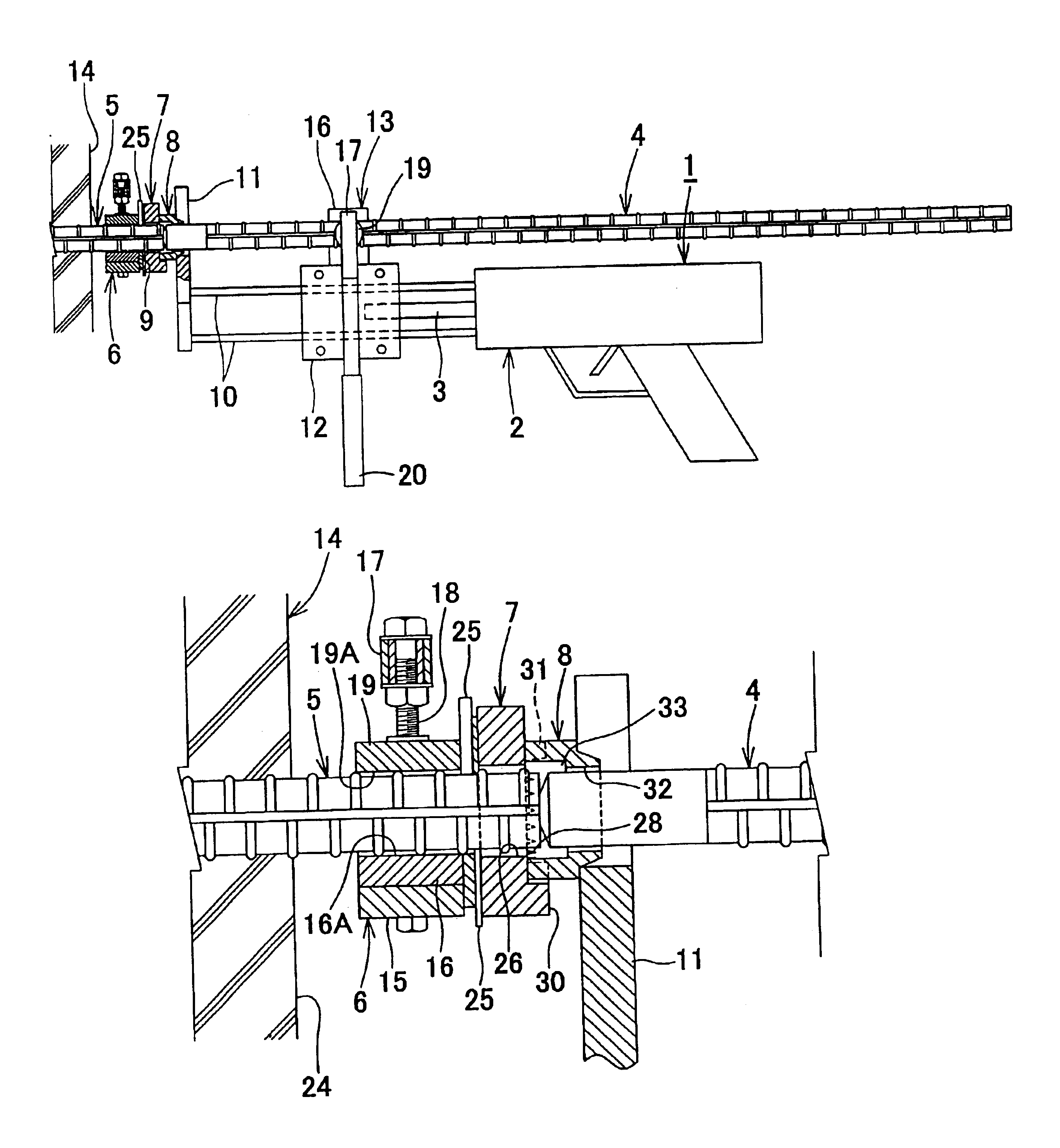

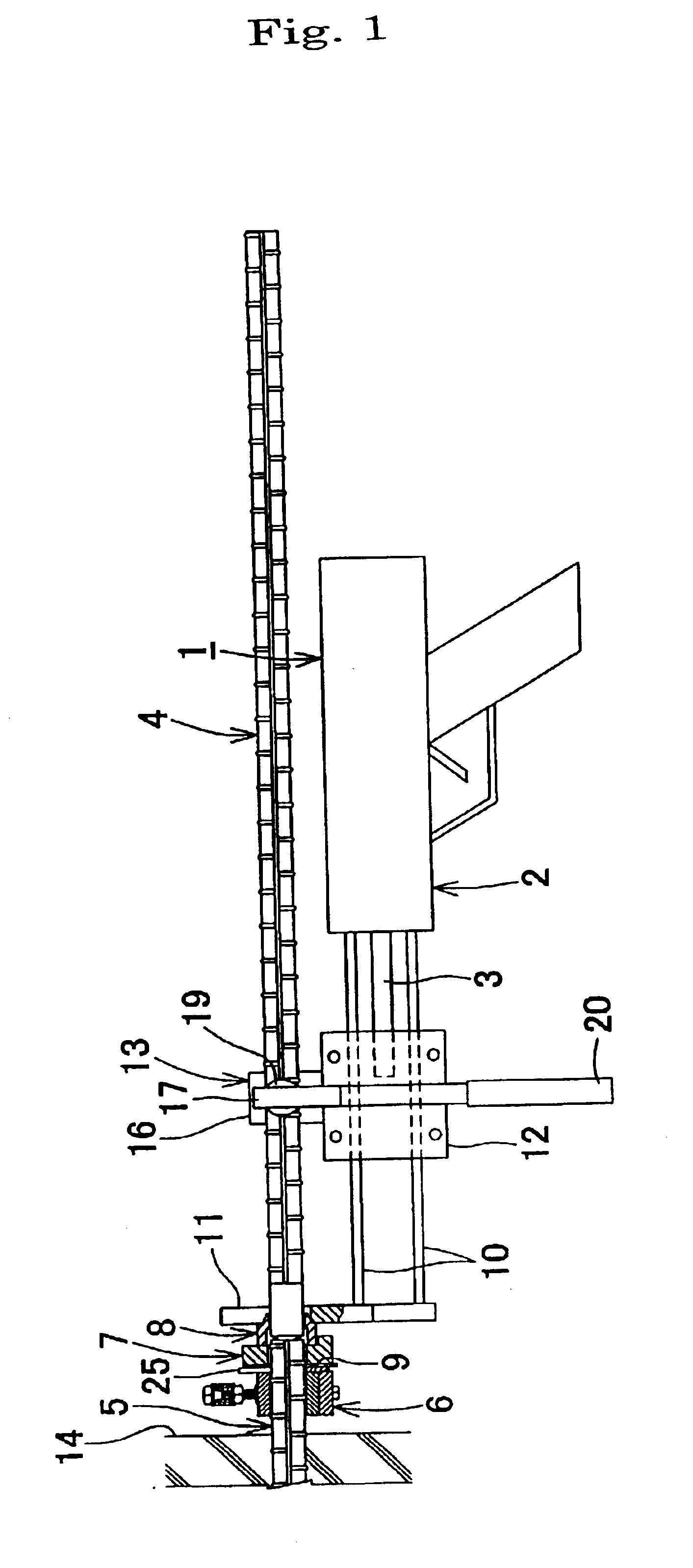

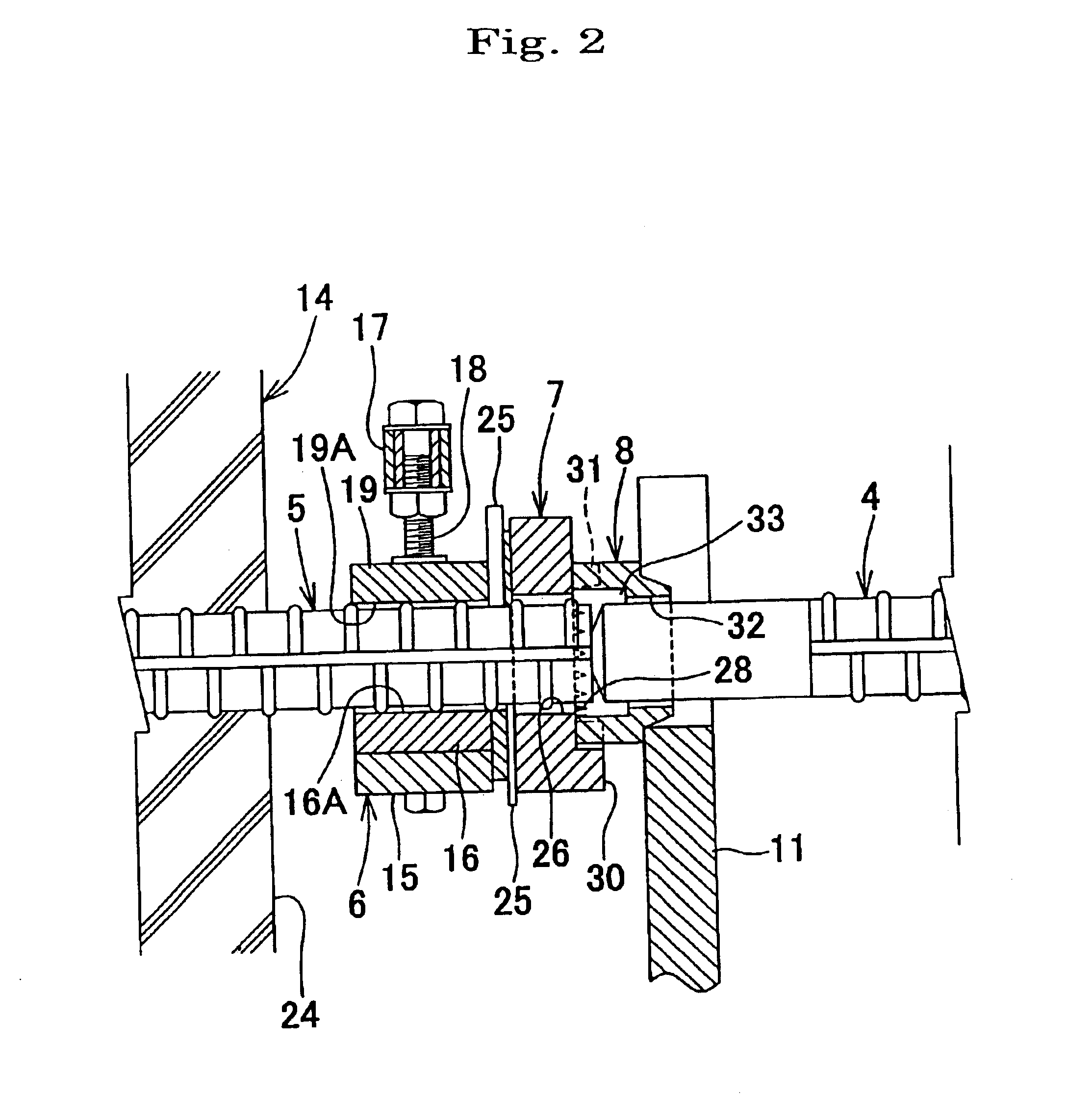

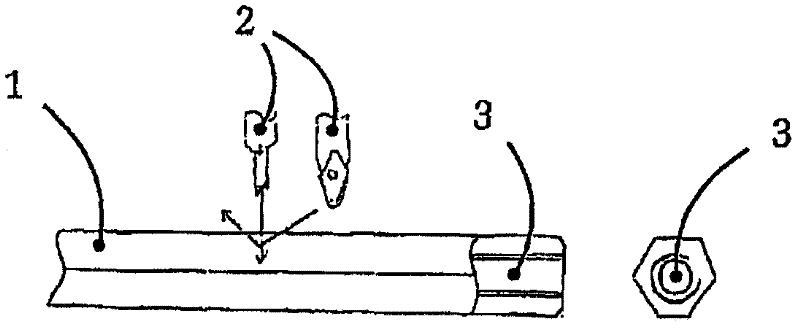

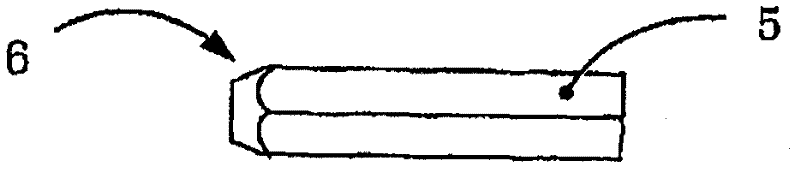

Reinforcement butt stud welding method and device therefor and repairing/expanding method for ferroconcrete structure

InactiveUS6906277B2Easy to weldReduce stepsSoldering apparatusBuilding repairsElectrical conductorReinforced concrete

A reinforcement butt stud welding method and a device therefore, capable of butt-welding a stud reinforcing bar coaxially to the end portion of a horizontally-laid existing reinforcement in a small work space; and a repairing / expanding method for a ferroconcrete structure. The reinforcement butt stud welding method includes the steps of fitting an earth clamp over the periphery of the end portion of the existing reinforcement, fitting an annular stud base that is a heat-resisting, insulating material to the conductor surface of the earth clamp by being pressed against the conductor surface, bringing the tip end of a stud reinforcing bar, loaded in a stud welding gun, into contact with the end face of the existing reinforcement, and keeping a ferrule disposed around the tip end portion of the stud reinforcing bar joined to the stud base to complete stud welding.

Owner:IHI CONSTR SERVICE

Laser welding method

ActiveUS10286491B2Long processing timeReduce strainLaser beam welding apparatusOptoelectronicsIrradiation

A laser welding method of the present disclosure has a first step and a second step. In the first step, a first workpiece and a second workpiece are overlaid in a first machining region. In the second step, the first workpiece and the second workpiece are irradiated with laser beam in the first machining region while the laser beam is moved in a spiral path. Moreover, in the second step, the first workpiece and the second workpiece are melted by irradiation of the laser beam to form a liquid phase portion. Furthermore, in the second step, the laser beam is moved so that the liquid phase portion is not irradiated with the laser beam again.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Forming process of moderate-thickness plate no-back-gouging butt joint full-penetration class-I component

InactiveCN104259624AFast molding speedGood effectWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The invention discloses a forming process of a moderate-thickness plate no-back-gouging butt joint full-penetration class-I component and relates to a moderate-thickness plate tailored-welding forming process. The forming process comprises the steps of preparing plates, cutting the plates to form process grooves, performing tailored welding on the plates, adding ceramic backings, iron liners, clamps and process triangular plates, performing single-side welding on the clamps and the process triangular plates to form single-side welding beads, adding a leading-in arc plate and a leading-out arc plate, welding two moderate-thickness plates, dismounting the ceramic backings, the iron liners, the clamps, the process triangular plates, the leading-in arc plate and the leading-out arc plate, polishing and repairing the single-side welding beads, performing ultrasonic inspection on the single-side welding beads, encoding and marking qualified products and performing next working procedures. The quality of weld joints is guaranteed, butt-jointed plates do not easily deform, production efficiency is high, on-site butt joint operation is quick and easy, lots of manpower resources can be saved, the labor intensity of workers can be reduced, and production cost can be reduced.

Owner:湖北源盛钢构有限公司

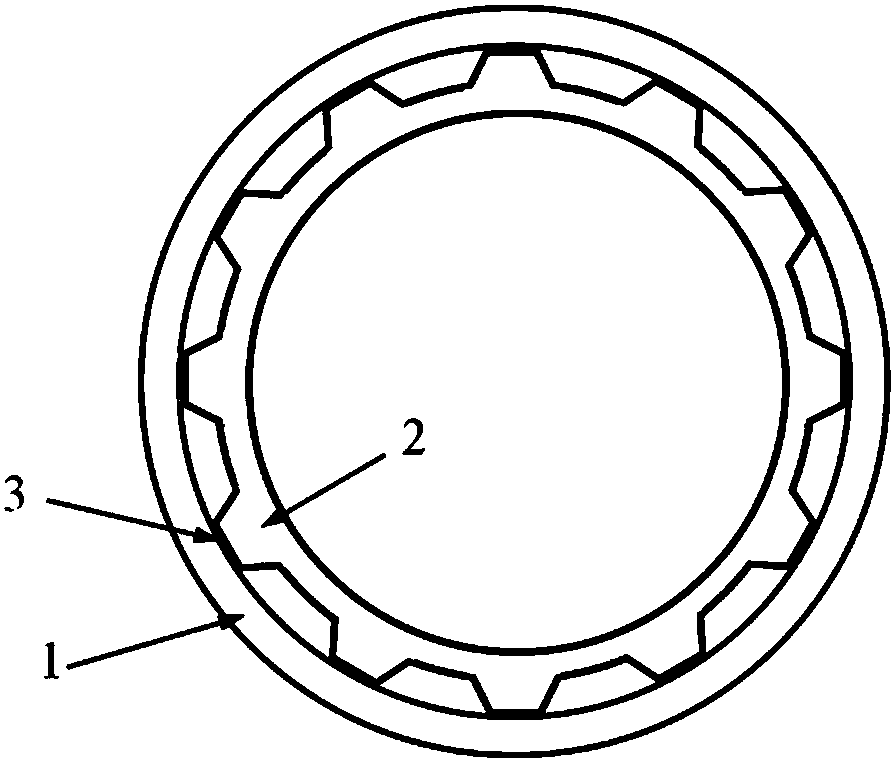

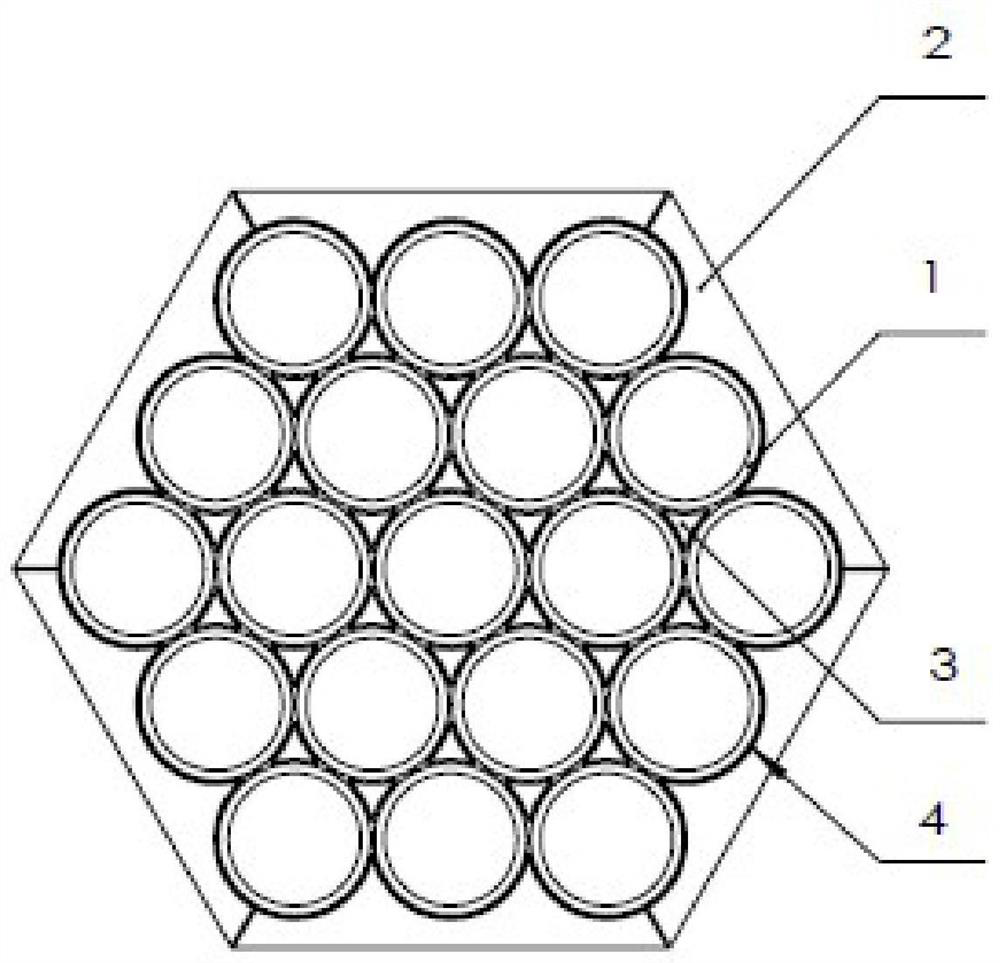

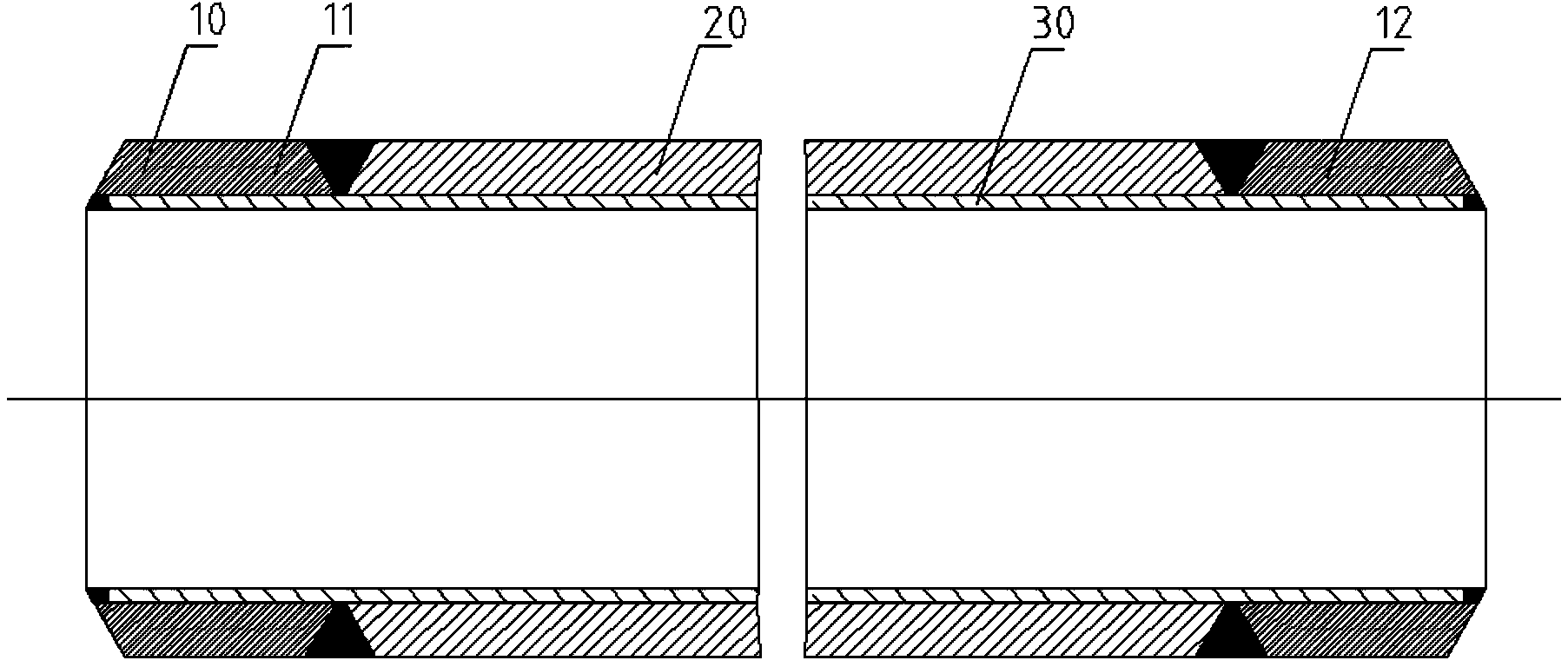

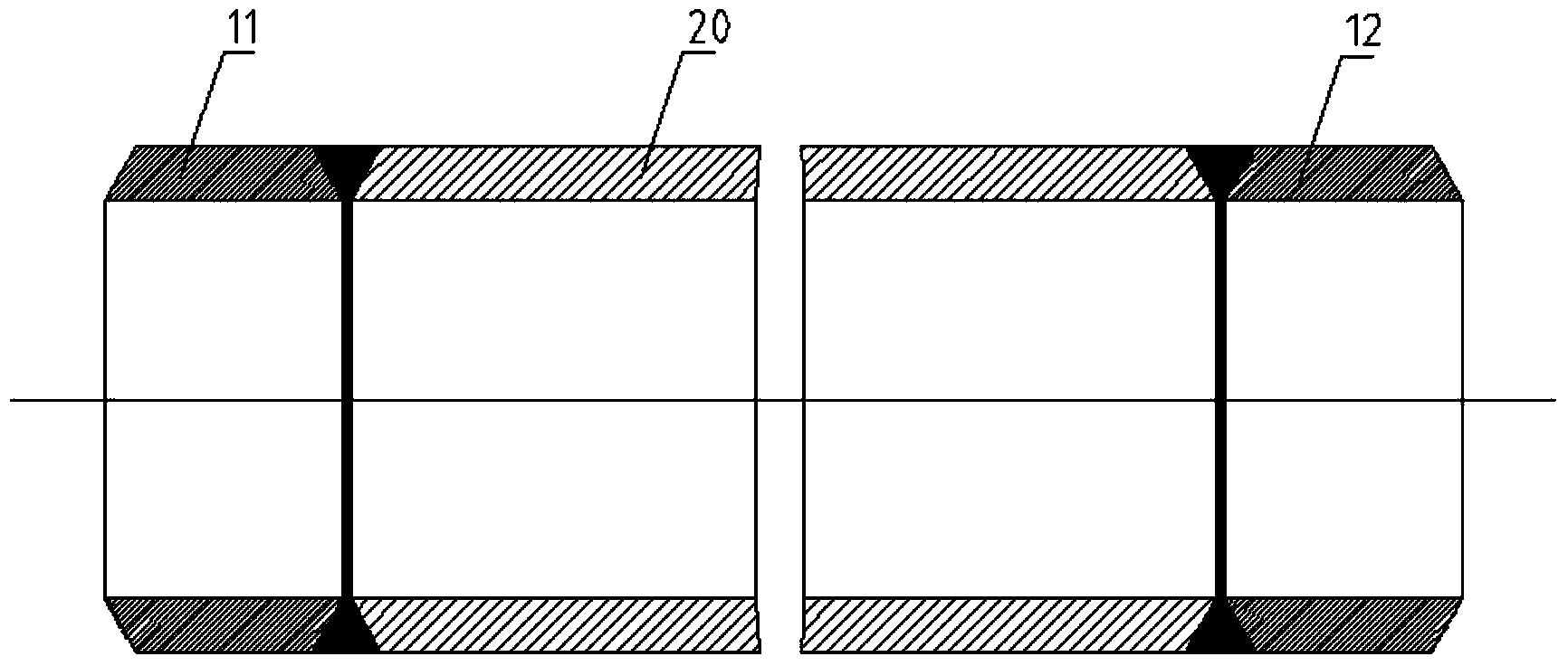

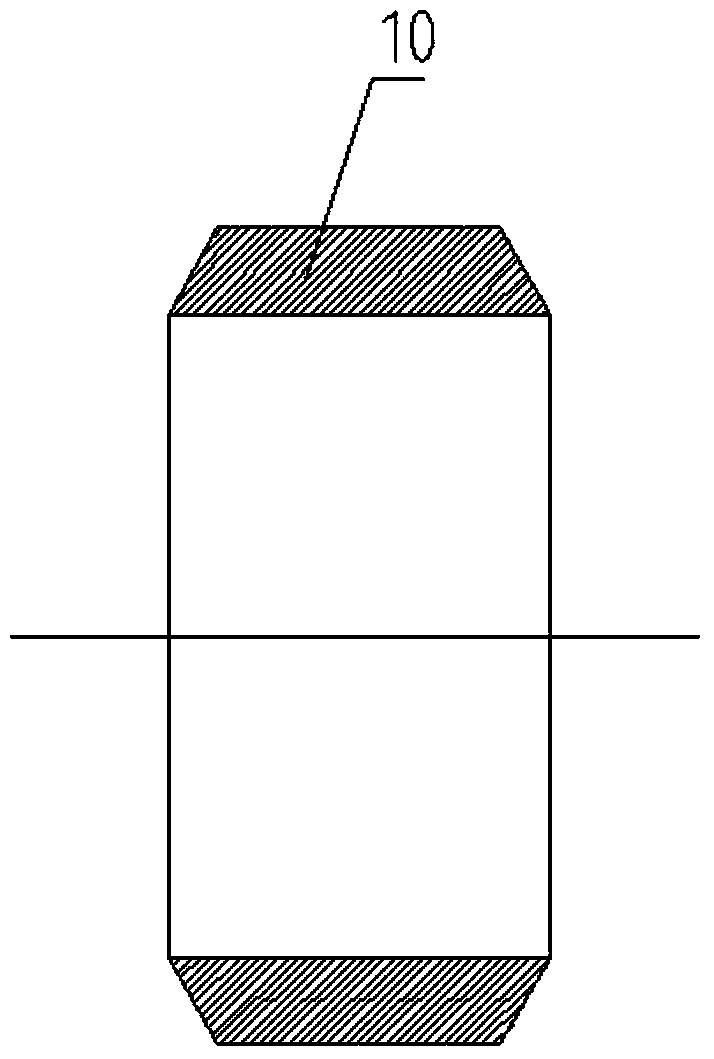

Diffusion connection method of cylinder wall structure

InactiveCN107671411AImprove uniformityQuality improvementNon-electric welding apparatusEngineeringLiquid nitrogen

The invention discloses a diffusion connection method of a cylinder wall structure. The diffusion connection method comprises the following steps of putting an inner cylinder wall in liquid nitrogen for 20-30 min and then rapidly mounting the inner cylinder wall into an outer cylinder wall to form a combined workpiece; conducting high-temperature diffusion welding on the combined workpiece and realizing diffusion connection of inner and outer cylinder wall structures through required diffusion welding pressure generated by deformation and interference installation of the workpiece at high temperature, wherein the inner diameter of the outer cylinder wall of the cylinder wall structure is 0.02-0.2% greater than the outer diameter of the inner cylinder wall; the temperature and time requiredfor diffusion connection are determined by the inner and outer cylinder diameter difference; the welding temperature can be reduced by 2-5 DEG C and the temperature holding time can be reduced by 1-2min every 0.01% increase in the outer diameter difference. By means of the diffusion connection method, the structure and process are simplified, and the uniformity and product quality of the weldingsurface can be improved; the diffusion connection method is applicable to welding conditions of columnar, conical, trapezoidal cylindrical and various cylinder wall structures.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Piping for refrigeration, production method and application

InactiveCN105004108AExcellent welding characteristicsWon't burn throughMechanical apparatusFluid circulation arrangementEngineeringCopper

The invention provides a piping for refrigeration, a production method and application. The piping for refrigeration is compounded from a plurality of metal layers, wherein the metal layers comprise a metal base layer, a side wall formed on the metal base layer and at least one copper cover layer used for being welded with an external part. The piping for refrigeration provided by the invention can totally replace the composite structure of a piping and a connecting piece of the conventional refrigeration device, so that the welding procedure is greatly decreased, and the welding cost is reduced.

Owner:何珠华

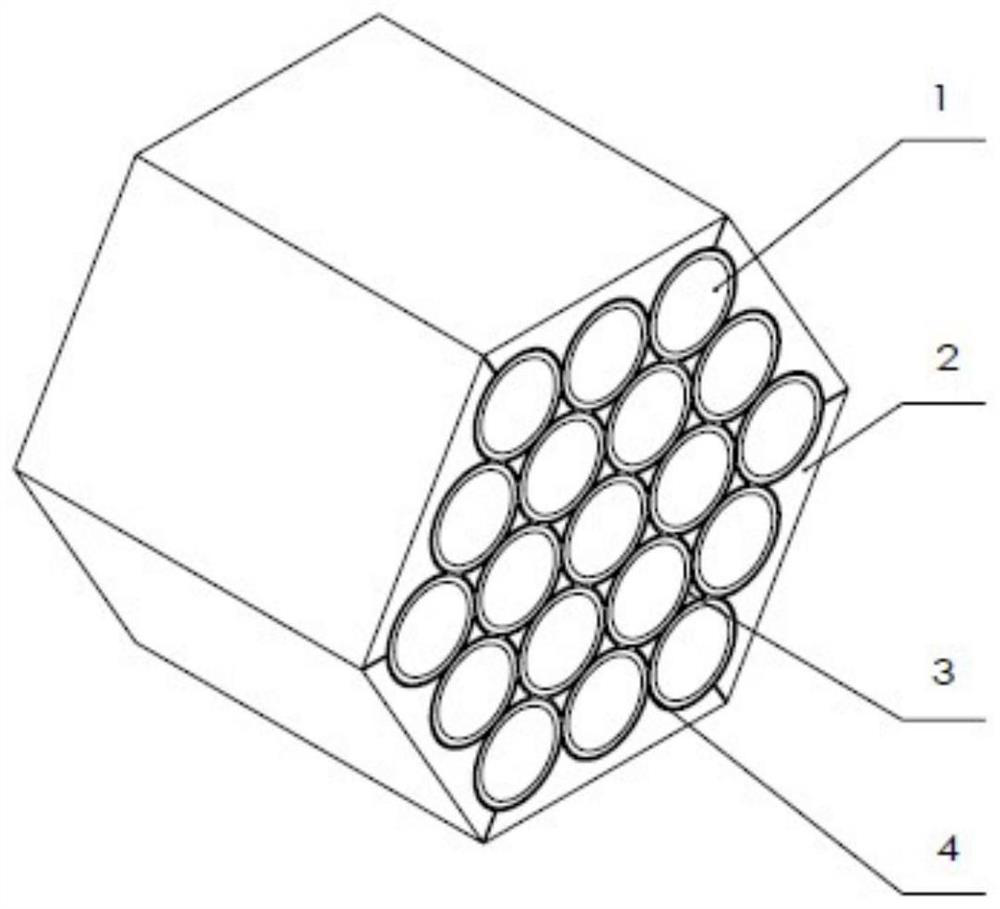

Stainless steel honeycomb type heat exchanger and vacuum brazing method thereof

InactiveCN112775512AImprove structural strengthIncrease profitStationary conduit assembliesHeat exchanger casingsHoneycombHeat conservation

The invention discloses a stainless steel honeycomb type heat exchanger and a vacuum brazing method thereof.The brazing method comprises the steps: firstly, cleaning surfaces of heat exchanger components; secondly, coating the surfaces of all the components with brazing filler metal and then assembling the same by an assembly tool; and then putting the components into a vacuum furnace to be subjected to heat preservation and preheating so as to obtain good welding conditions, so that heat input in the welding process is ensured to be uniform and stable, finally brazing is conducted, and furnace cooling is conducted to the room temperature; the stainless steel honeycomb type heat exchanger is formed by splicing stainless steel profiles, so that the material utilization rate is high, and the cost is saved. The honeycomb type heat exchanger is formed through vacuum brazing fixing with small parts, so that the overall structure is simple. The round pipes and the triangular prisms are positioned and assembled through a tool after the outer frame is welded, vacuum one-time brazing forming is achieved, and the production efficiency is high; and brazing seam tissues are uniform, and the component structural strength is high.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

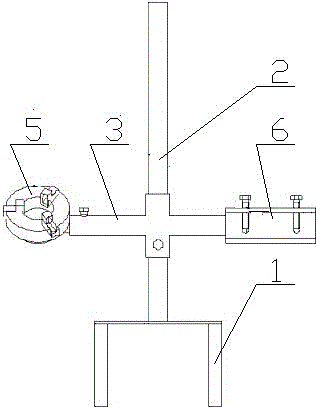

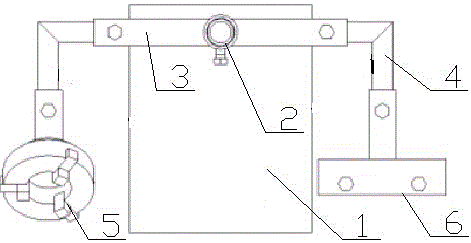

Welding workpiece clamping device with multi-angle adjusting function

InactiveCN106363335AComprehensive clamping functionSimple structureWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringWelding joint

The invention provides a welding workpiece clamping device with a multi-angle adjusting function. A supporting rod is welded to the upper end of a base. A height adjusting device can slide up and down, and the supporting rod is horizontally and rotationally sleeved with the height adjusting device in a 360-degree mode. A fastening bolt is arranged on the height adjusting device. Welding positioners are horizontally, rotationally and movably installed at the two ends of the height adjusting device in a 360-degree mode. Welding clamping devices are movably installed at the other ends of the welding positioners correspondingly. By adjusting the positions of weld joints, adjustment of the weld joints in rigorous positions and special-shaped structure forms is achieved, the welding quality and efficiency of workers are improved, and potential safety hazards are avoided.

Owner:XCMG CONSTR MACHINERY

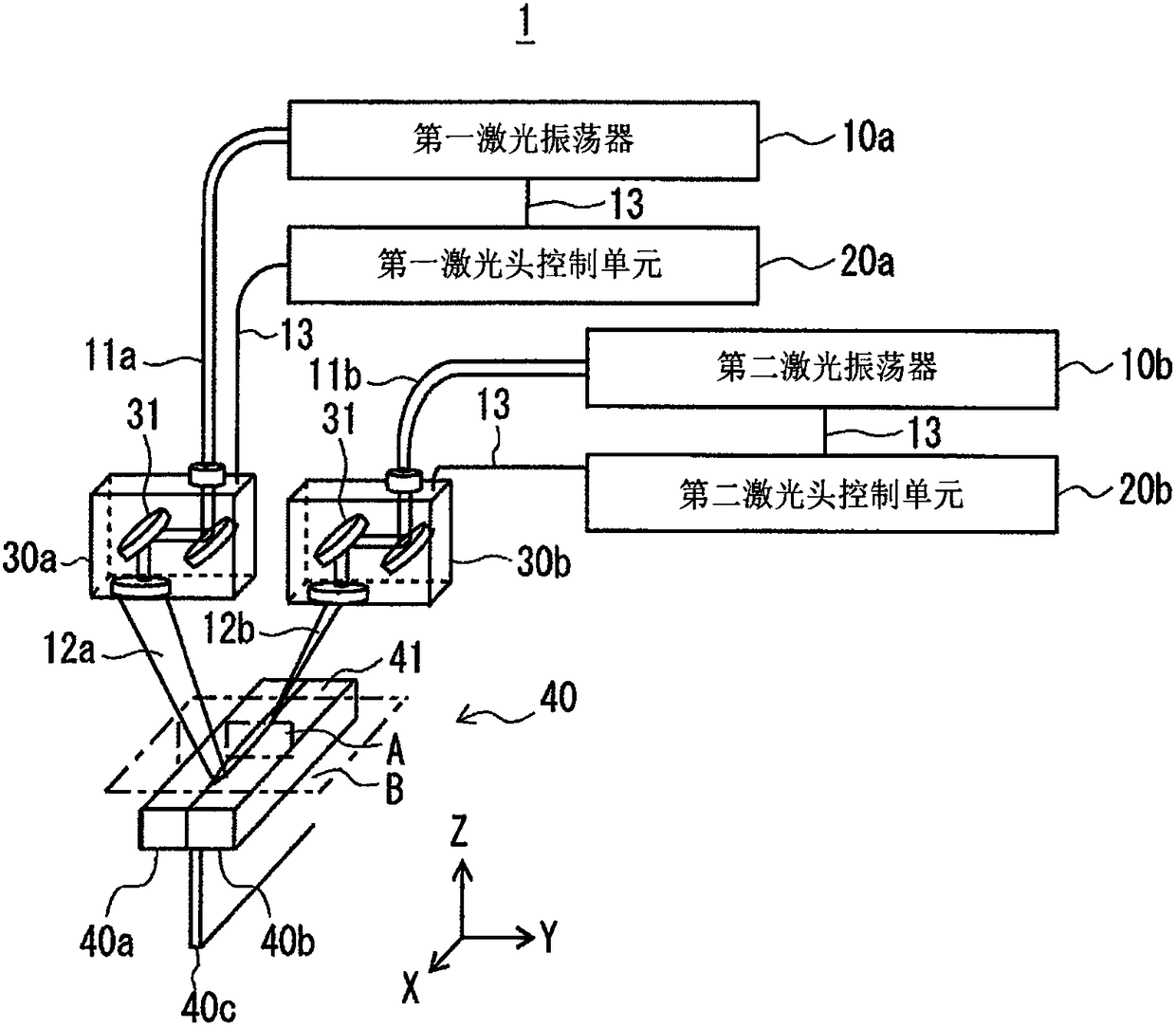

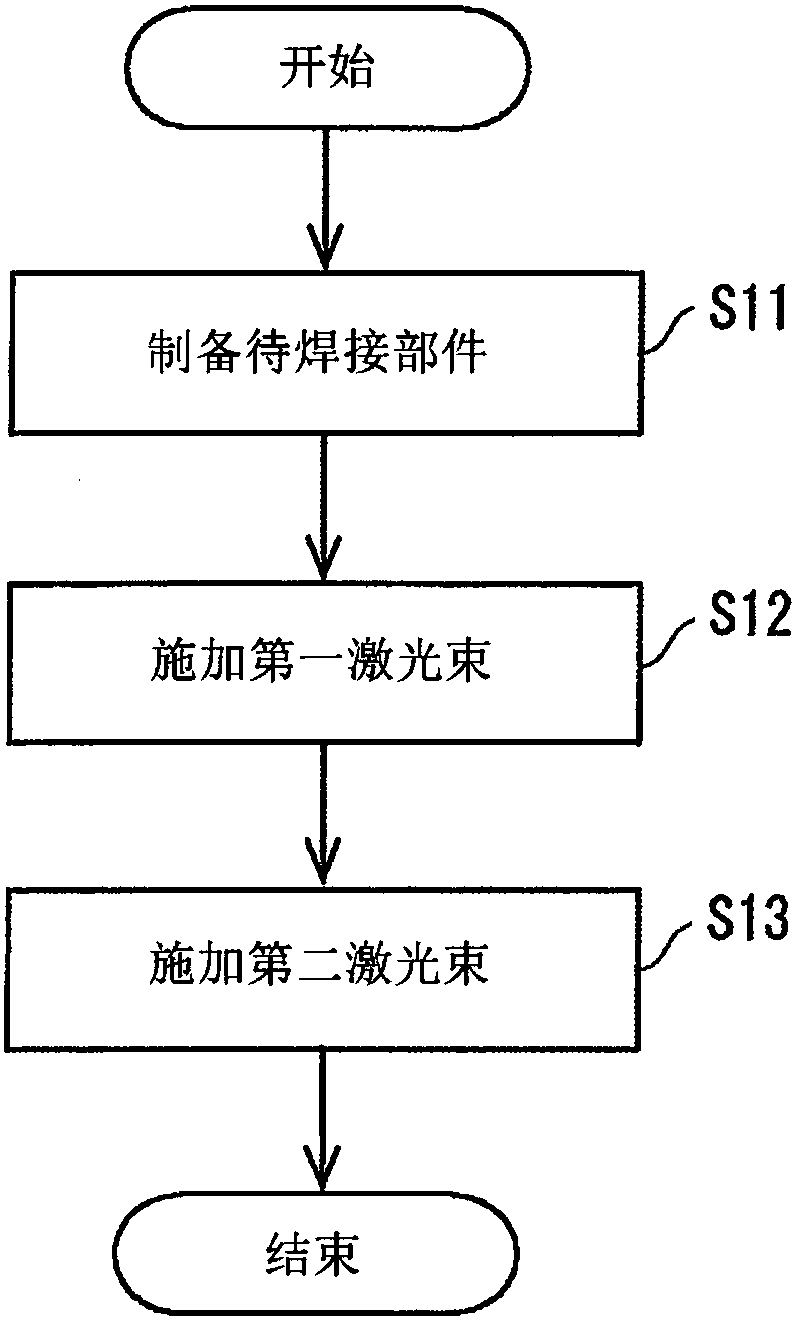

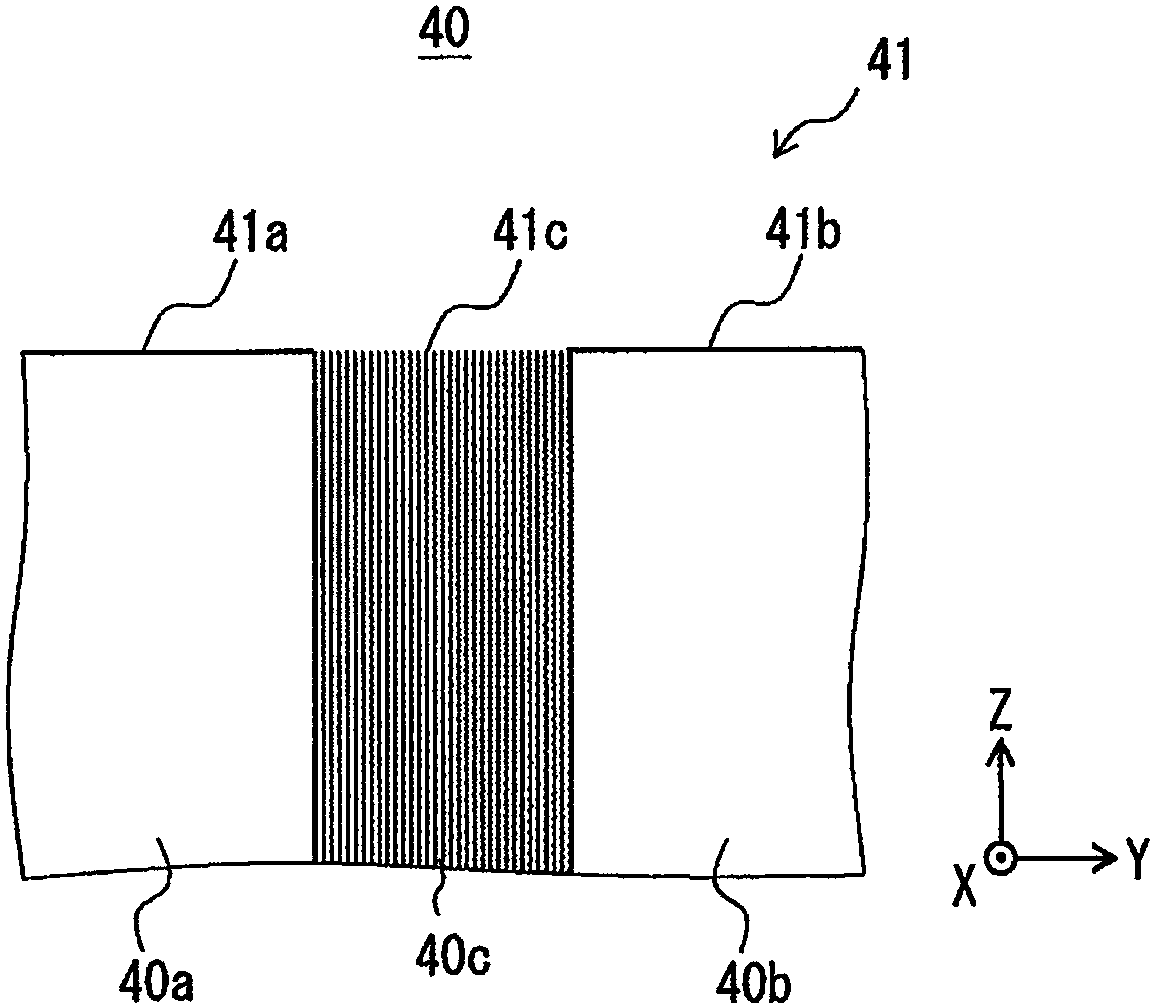

Laser welding method and laser welding apparatus

ActiveCN109093249AAvoid formingGood welding conditionConductorsMetal working apparatusOptoelectronicsLaser beams

A laser welding method and a laser welding apparatus capable of preventing formation of blowholes and obtaining an excellent welled state are provided. An embodiment is a laser welding method for a component to be welded 40 including a third metal component 40c sandwiched between first and second metal components 40a and 40b, in which the metal components are welded to each other by scanning a laser beam in a first direction perpendicular to a direction in which the third metal component 40c is sandwiched, in which a welded part 42 is formed by applying a first laser beam 12a while scanning itin the first direction and thereby melting and then solidifying the component to be welded 40.

Owner:TOYOTA JIDOSHA KK

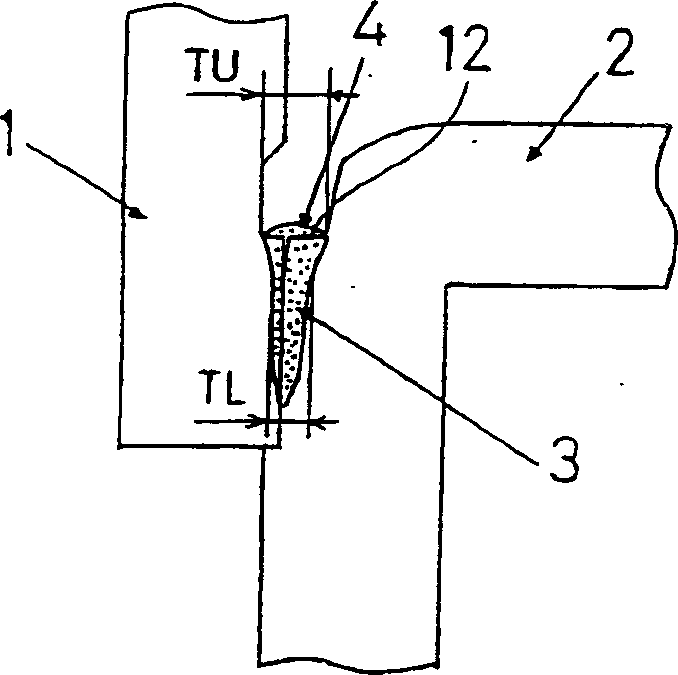

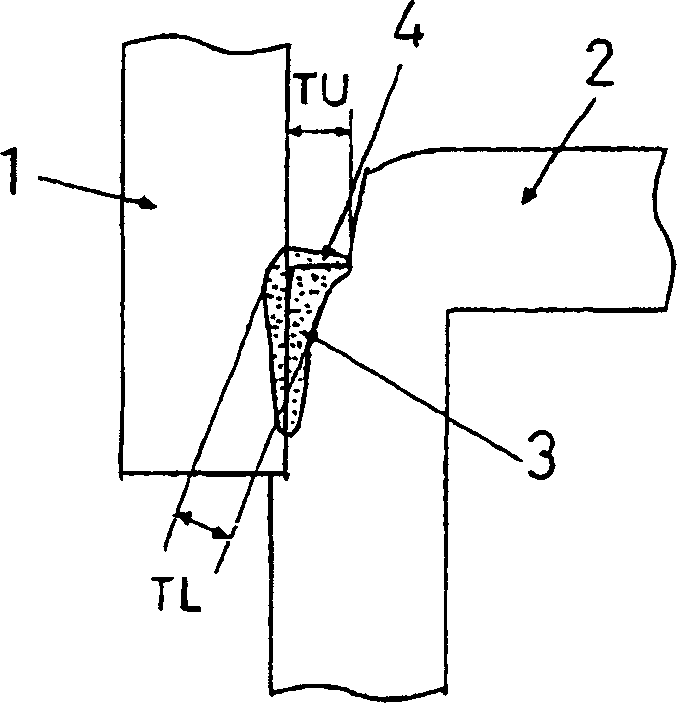

Laser welded tube fitting structure and gas generator with the tube fitting structure

InactiveCN1638914AImprove reliabilitySimple structurePedestrian/occupant safety arrangementMetal working apparatusEngineeringExpansion joint

A laser welded joint structure, which is a laser welded joint structure of a flared joint, is provided with an I-shaped groove-shaped flat portion ( 4). A gas generator having the aforementioned laser welded joint configuration.

Owner:NIPPON KAYAKU CO LTD

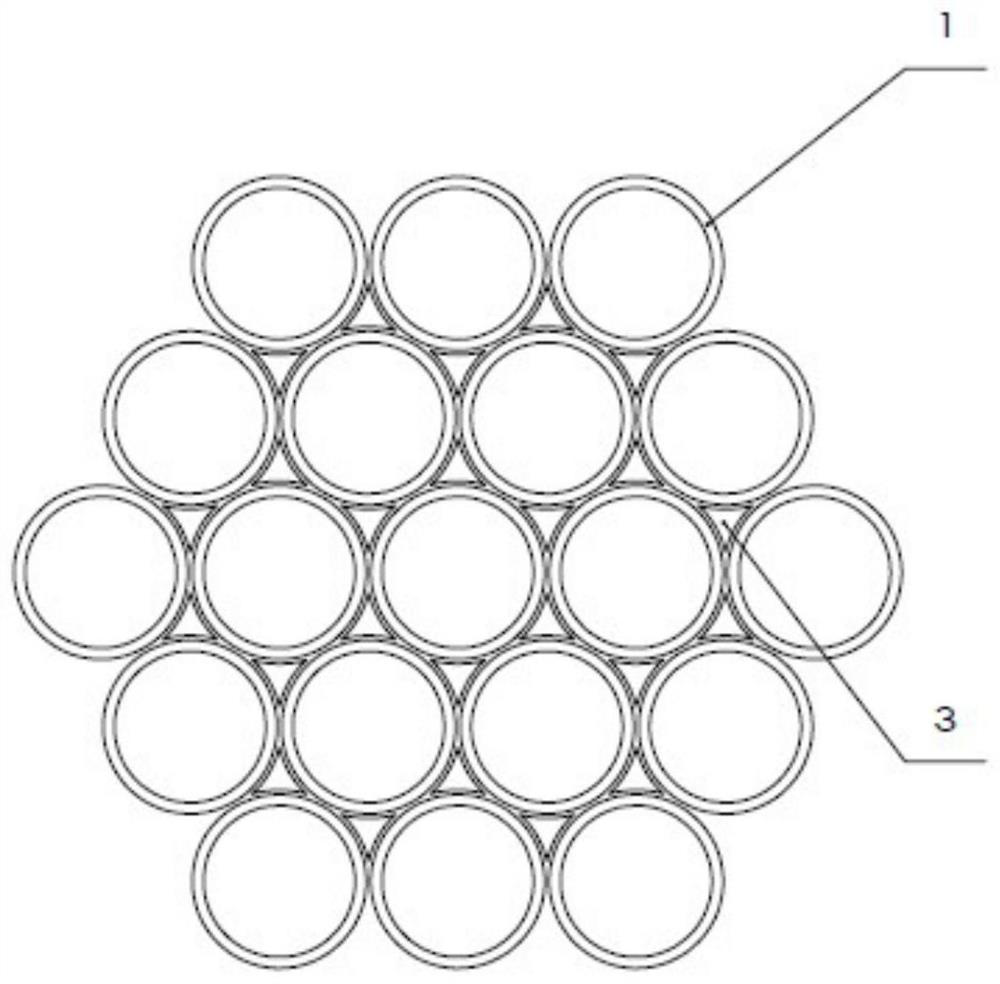

Bimetal composite tube

InactiveCN103486341AEnsure safetyEasy to weld on siteCorrosion preventionPipe protection against corrosion/incrustationWeld strengthUltimate tensile strength

The invention discloses a bimetal composite tube which comprises an outer tube, connecting portions and an inner tube. The connecting portions are arranged at one end or two ends of the bimetal composite tube, the connecting portions and the inner tube are made of identical materials, the inner diameter of each connecting portion is consistent with that of the outer tube, and the wall thickness of each connecting portion is not smaller than the wall thickness of the outer tube; the outer tube is connected with the connecting portions by means of welding; the inner tube is tightly combined with the outer tube and the connecting portions by a certain forming method; the ends of the inner tube and the ends of the connecting portions are subjected to seal welding, so that corrosive media in pipelines are guaranteed against being in contact with the outer tube. The bimetal composite tube has the advantages that special materials among the connecting portions of the composite tube and the outer tube are welded in a manufacturing plant, so that a welding condition is good, quality inspection can be strictly executed conveniently, the welding strength can be guaranteed, only welding of the same type of metal needs to be completed during field construction, and the requirement on the connection strength between the pipelines can be met; the connecting portions are made of the corrosion-resistant materials, so that corrosion of the connecting portions can be prevented, and the delivery safety performance of the bimetal composite tube can be guaranteed.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

An Ultrasonic Assisted Semi-solid Welding Method

InactiveCN105522246BImprove mechanical propertiesEasy to useSoldering apparatusUltrasonic assistedUltrasonic welding

Owner:HARBIN INST OF TECH AT WEIHAI

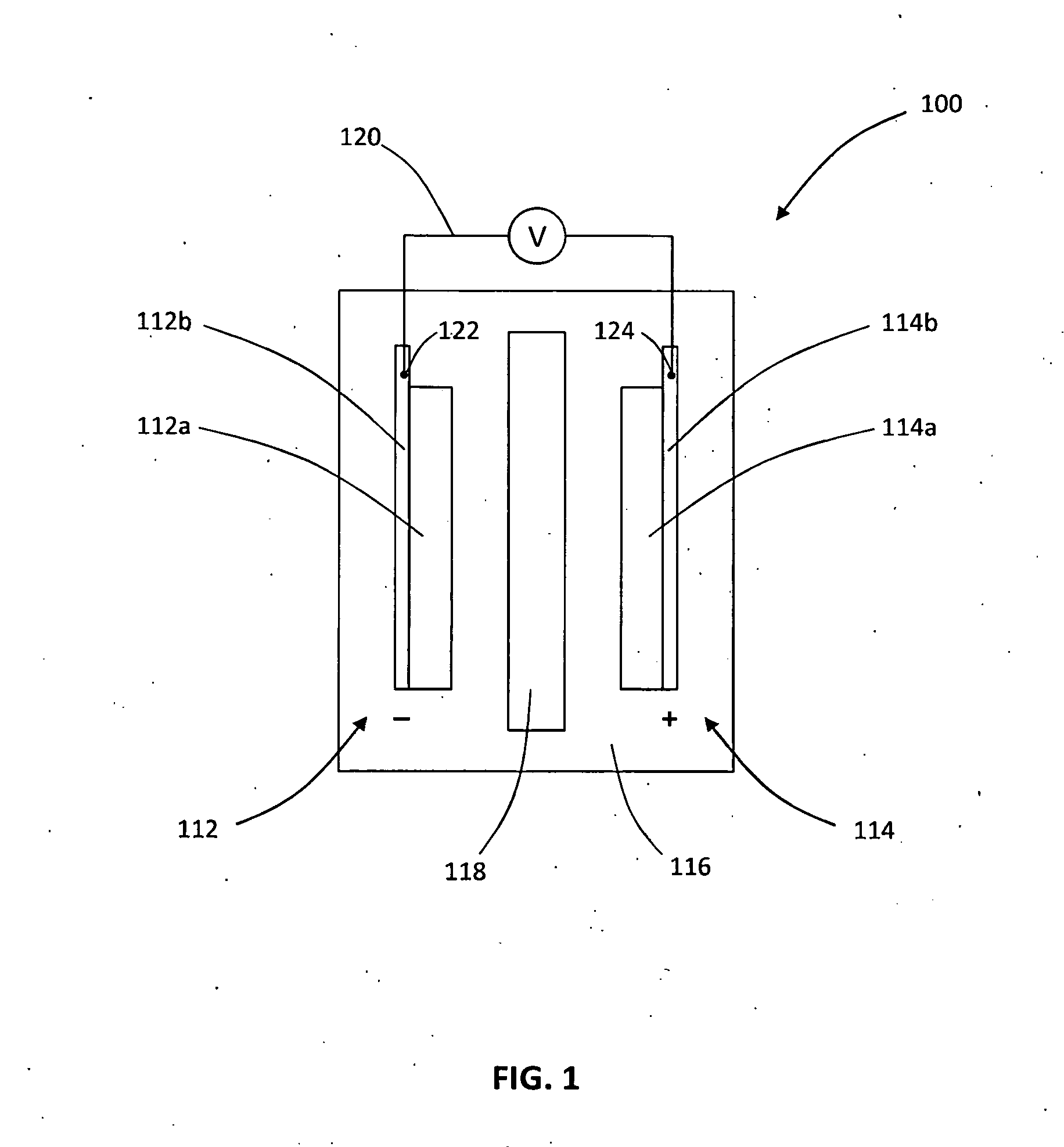

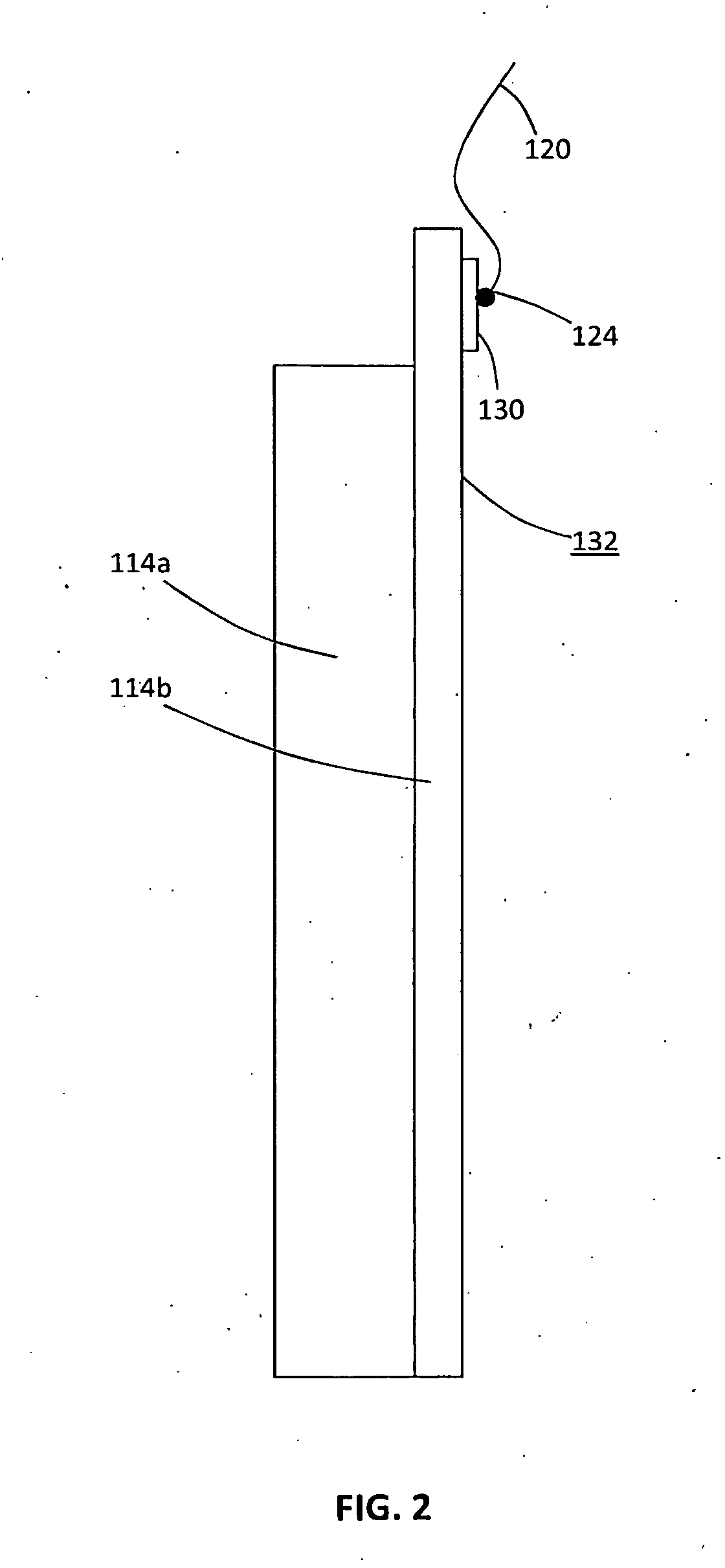

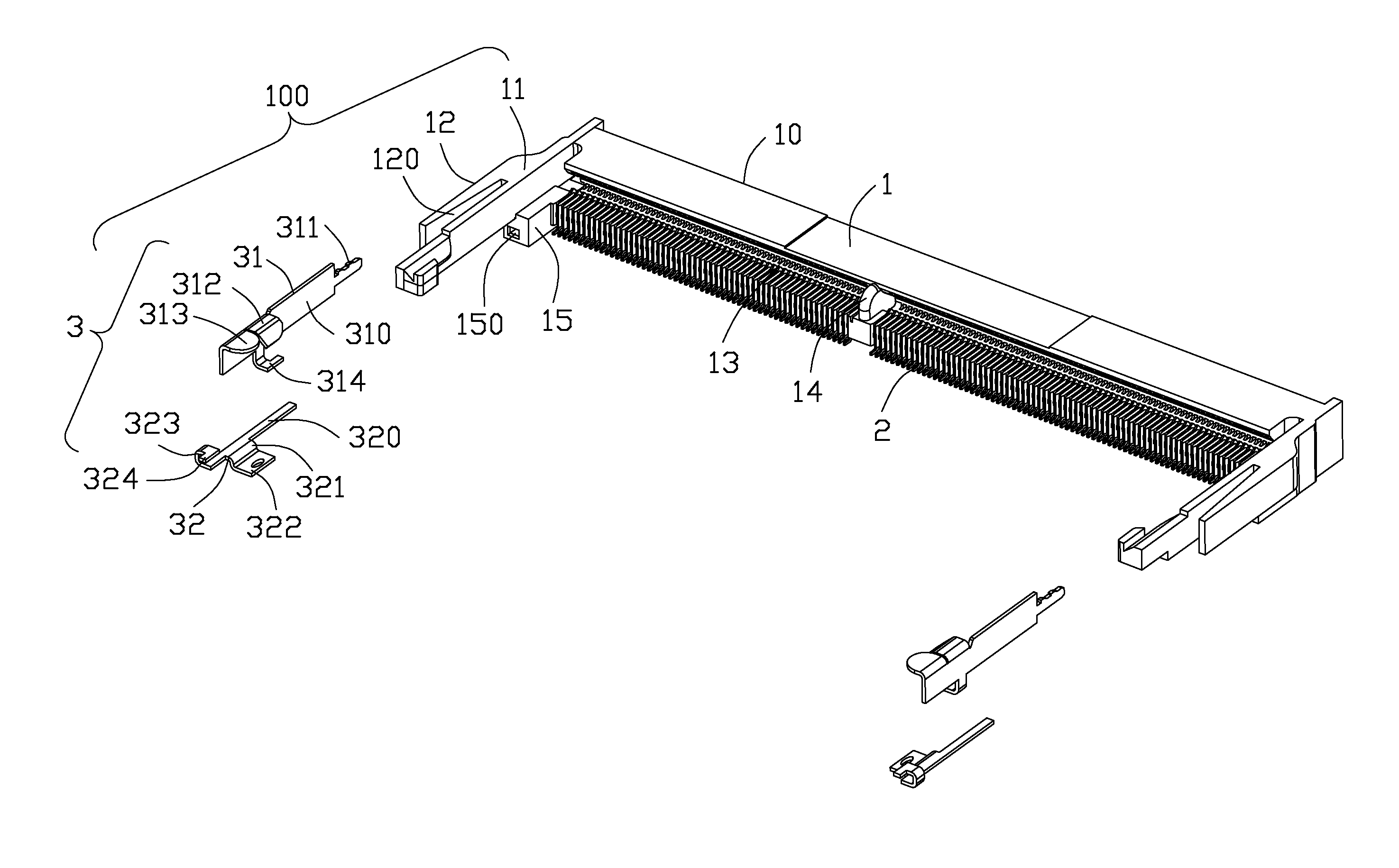

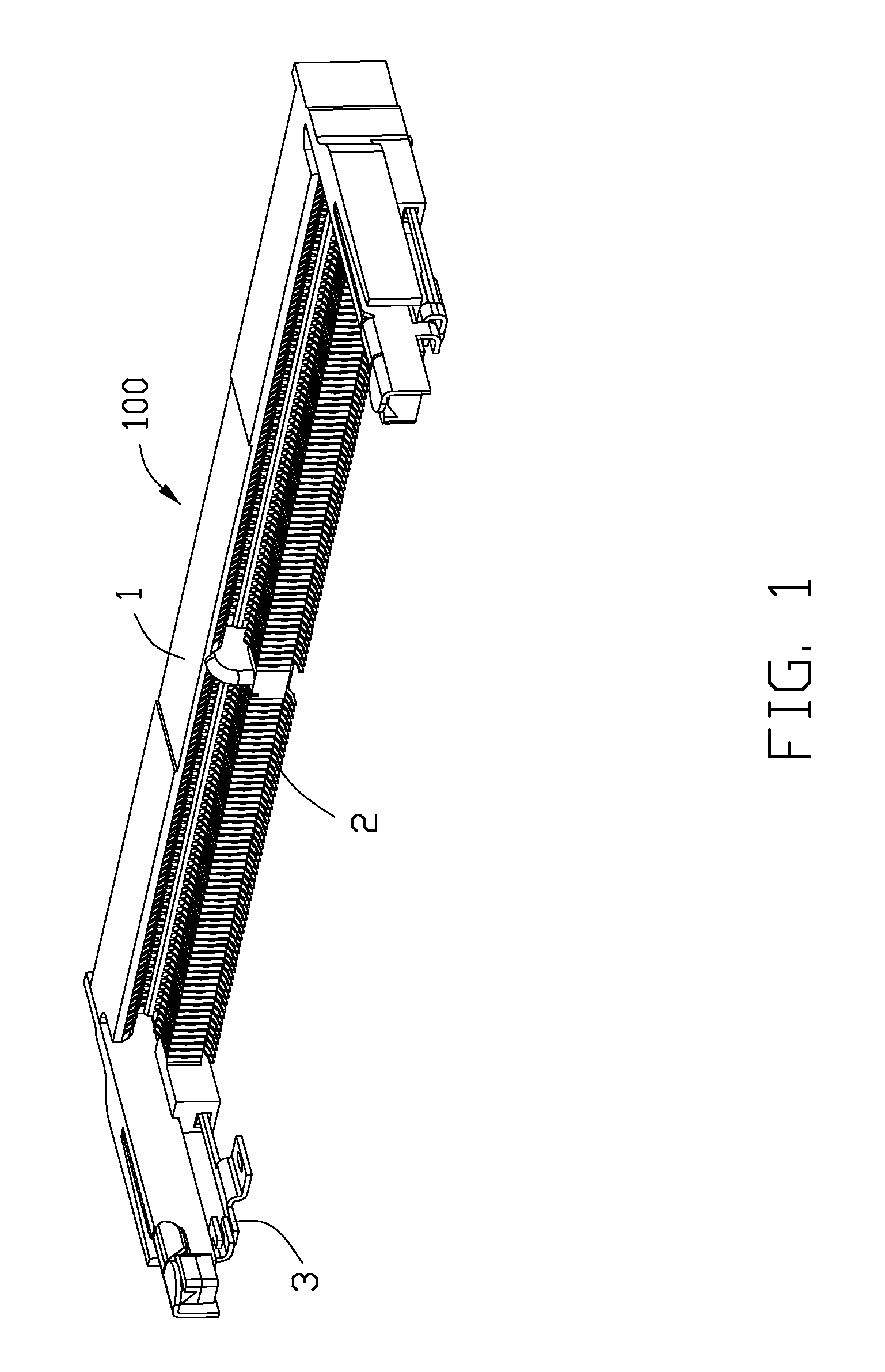

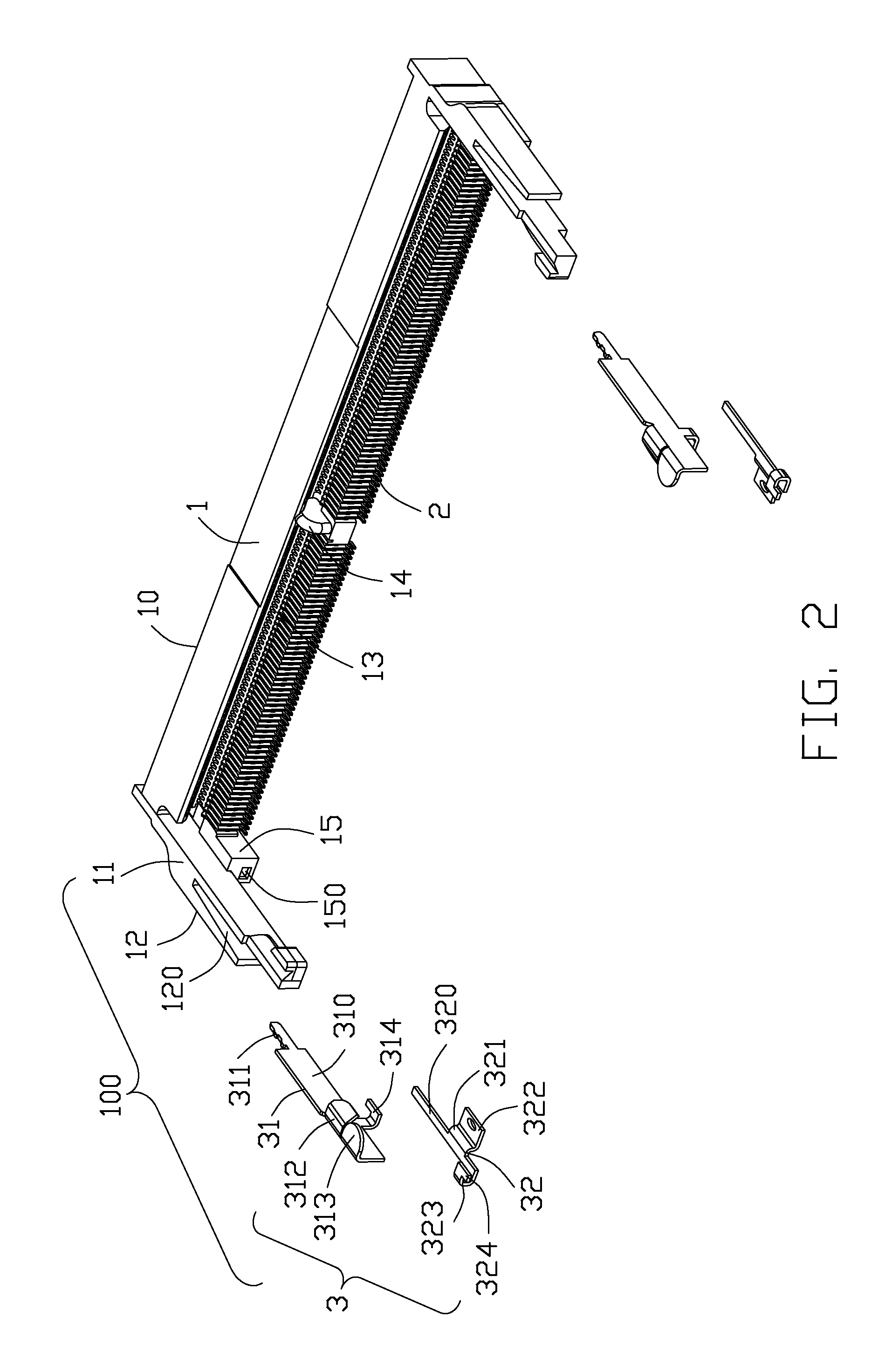

Card edge connector with floating metal member

ActiveUS8961211B2Good welding conditionEngagement/disengagement of coupling partsEngineeringMechanical engineering

A card edge connector includes an insulative housing, a plurality of conductive terminals and a pair of metal members attached to the insulative housing. The insulative housing defining a pair of latching arms integrally extending forwardly from opposite ends thereof and a mounting slot below said each latching arm. Each metal member including a first metal member closely and vertical attached to the latching arm and a second metal member movably received in the mounting slot. wherein the first metal member defines a stopping portion extending to the second metal member, the second metal member defines a solder portion and a stopped portion extending to the stopping portion, the stopping portion is located in front of the stopped portion in a front-to-rear direction, thereby the second metal member is prevent from forwardly departing from the mounting slot by the stopping portion of the first metal member.

Owner:HON HAI PRECISION IND CO LTD

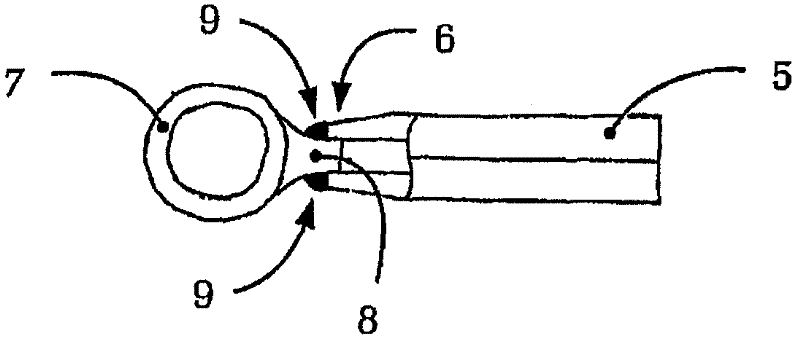

Ball-and-socket joint

InactiveCN102312915ARotational friction weldingIncrease the modulus of bending sectionBearing assemblyShaft assemblyStress concentrationWeld seam

The joint has a shaft (5) and a ball joint (7,11) frictionally welded with one another as separate components in an electrical resistance manner. A spigot (8) is formed at the ball joint, and the shaft is welded with the spigot. The shaft is formed with two fork ends in a region of a connection with the ball joint. The shaft is formed as a tubular semi-finished material with an integrated screw thread (3). A chamfer is welded with the ball joint. A weld seam (9) is moved from a surface area of the ball joint into a region of a transition between the spigot and the chamfer at the shaft. The joint provided in the invention has the advantages of low manufacturing cost, reliable manufacture, small stress concentration effects and high fatigue strength, especially low manufacturing cost and high part strength.

Owner:ZF FRIEDRICHSHAFEN AG

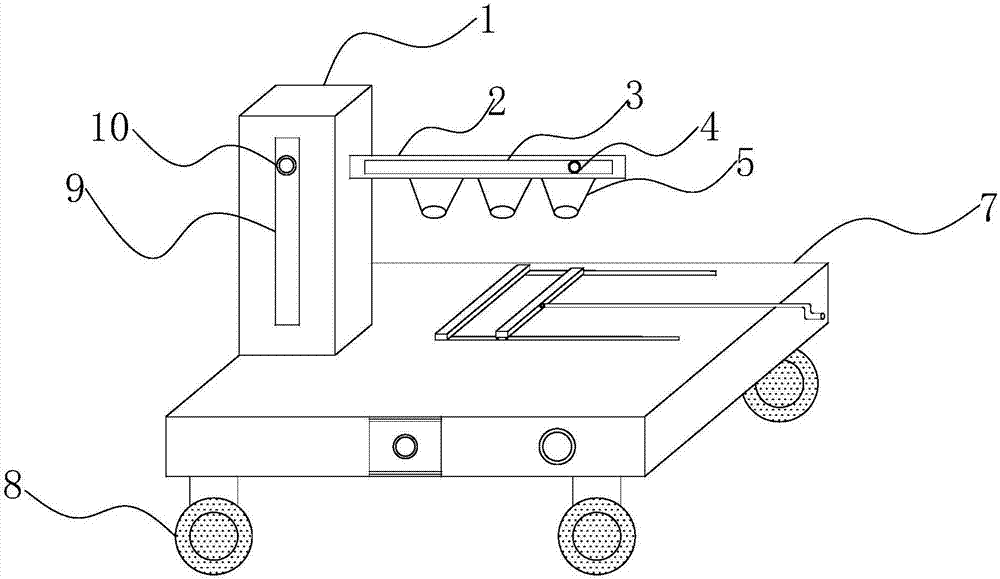

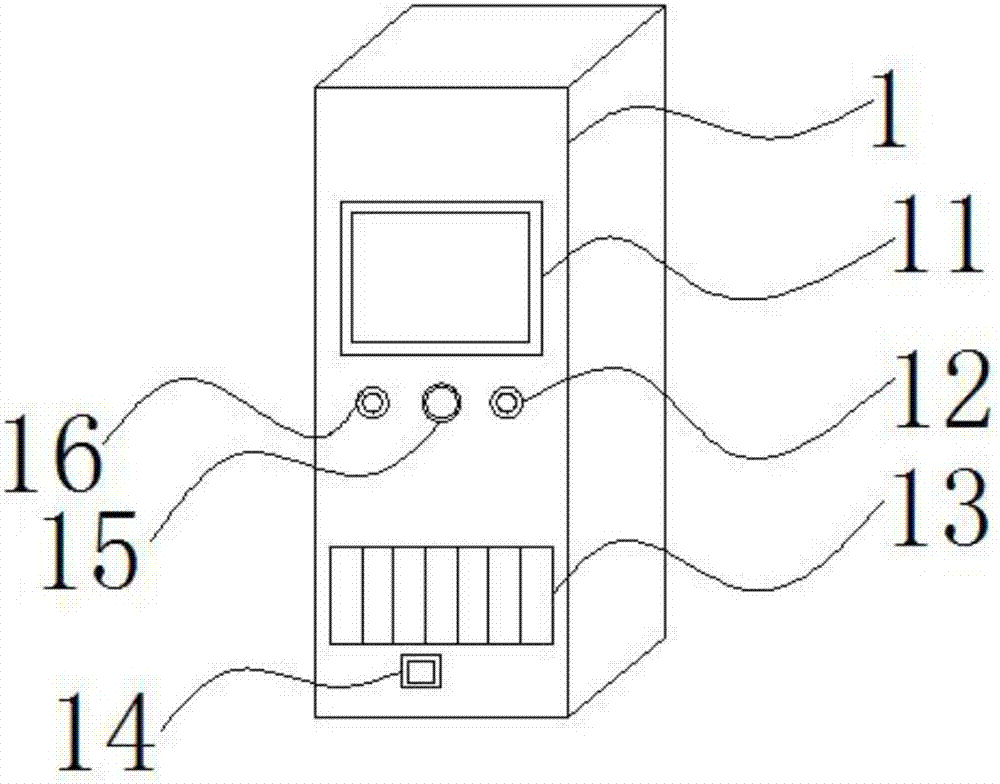

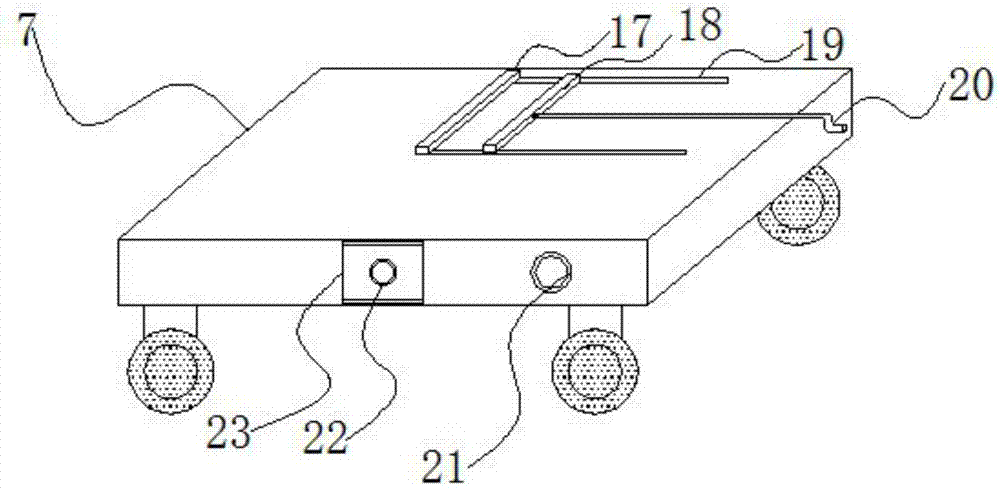

Metal production welding equipment

ActiveCN107097034AImprove welding efficiencyAccurate welding positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMode switch

Disclosed is a metal production welding equipment. The metal production welding equipment comprises a horizontal connecting rod and a welding equipment base. The left side of the upper end of the welding equipment base is provided with a vertical connecting rod. The front side of the vertical connecting rod is provided with a regulating stand rod. A second regulating button is arranged at the inner side of the regulating stand rod. The upper end of the left side of the vertical connecting rod is provided with a display screen. The left side of the lower end of the display screen is provided with a temperature switch button. A power switch button is arranged at the right side of the temperature switch button. A mode switch button is arranged on the right side of the power switch button. The lower end of the mode switch button is provided with a solar panel. The solar panel switch button is arranged at the lower end of the solar panel. The right side of the vertical connecting rod is provided with a horizontal connecting rod. A regulating horizontal rod is arranged in the horizontal connecting rod. A first regulating button is arranged in the regulating horizontal rod. By adjusting the horizontal rods and the vertical rods to change the height and the width, the metal production welding equipment is charged by the solar panel when the power is off; and the metal production welding equipment is simple in structure and convenient to use.

Owner:宁波宏恒模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com