Printed circuit board with improved pad structure

A technology of printed circuit boards and pads, which is applied in the direction of printed circuits, printed circuits, printed circuit manufacturing, etc., and can solve the problems of lowering the overall level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Reference will now be made in detail to the detailed embodiments of the present invention in conjunction with the accompanying drawings, wherein like elements are numbered identically. The following embodiments are for explaining the present invention with reference to the figures.

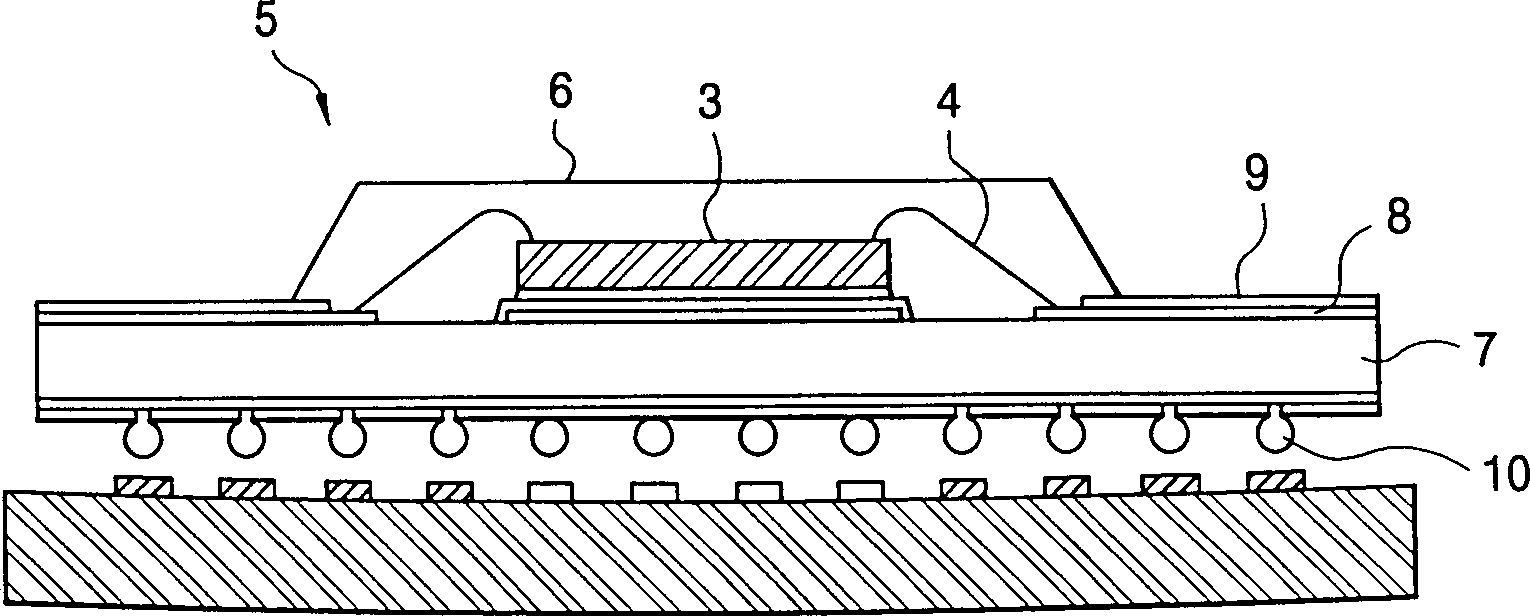

[0020] Such as figure 1 As shown, a BGA (ball grid array) package, as an example of a semiconductor chip package, is mounted on a printed circuit board according to the present invention, which is composed of a substrate 7 made of epoxy resin on A circuit pattern 8 formed on the substrate 7, a solder mask 9 coated on the circuit pattern 8, a semiconductor chip 3 mounted in the center of the substrate 7, and a wire 4 electrically connecting the circuit pattern 8 and the semiconductor chip 3. The semiconductor chip 3 and wires 4 are covered with a resin layer 6 to prevent oxidation and corrosion.

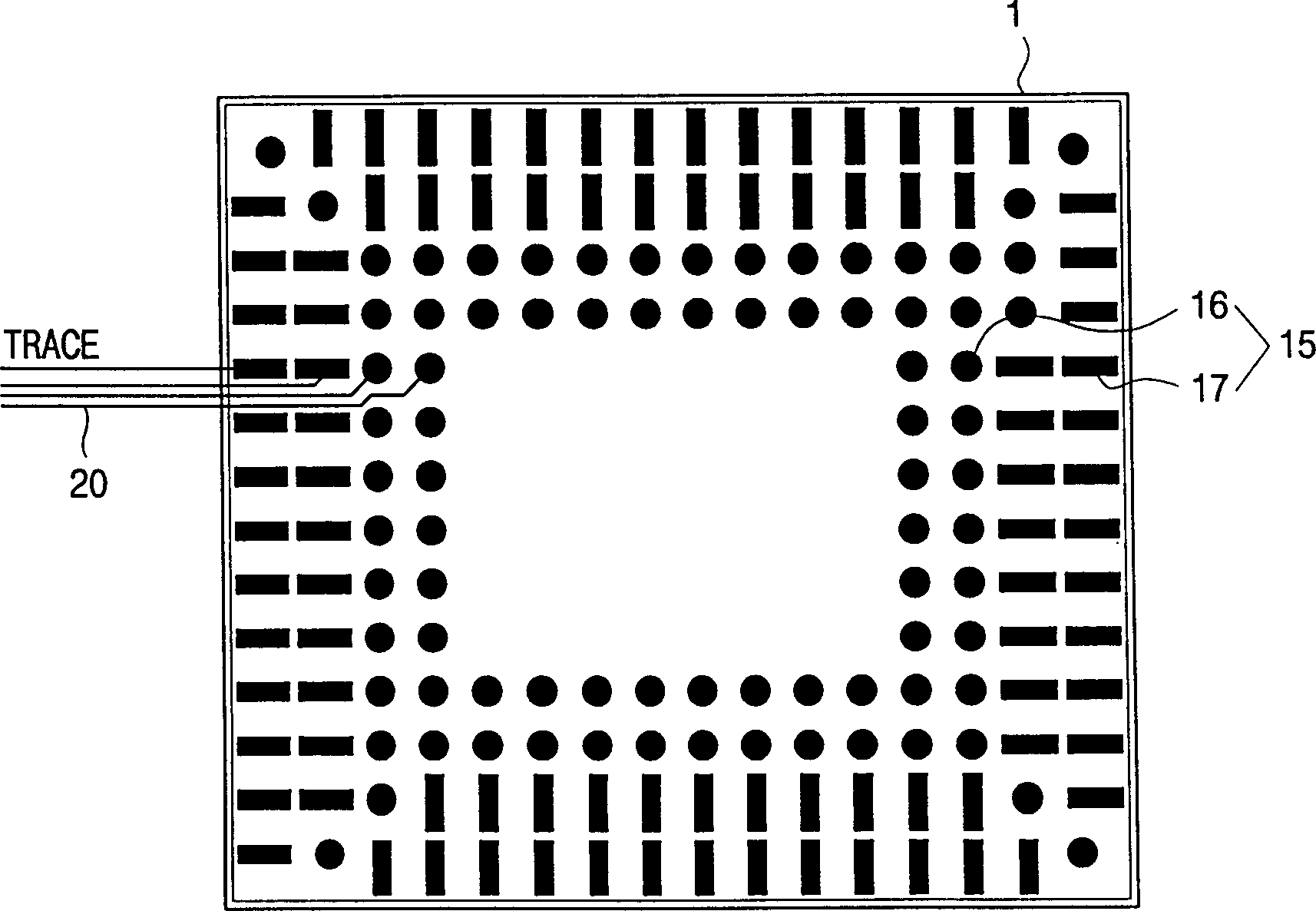

[0021] In the face of the printed circuit board 1 (refer to figure 2 ) has a plurality of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com