Ultrasonic-assisted semi-solid welding method

A technology of ultrasonic assistance and welding method, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem that the quality of the intermediate layer and the end face cannot meet the requirements, and achieve finishing processing and surface strengthening, and high production efficiency. , good welding conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

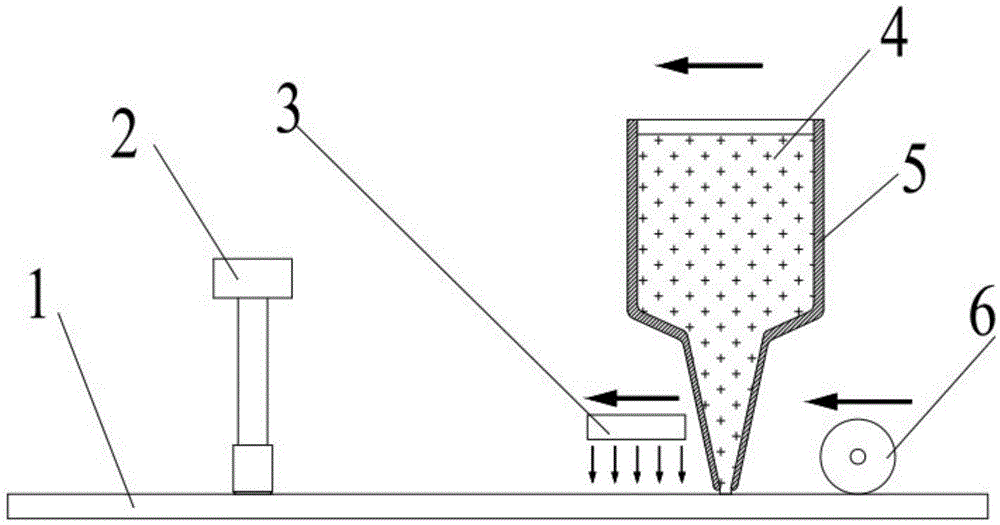

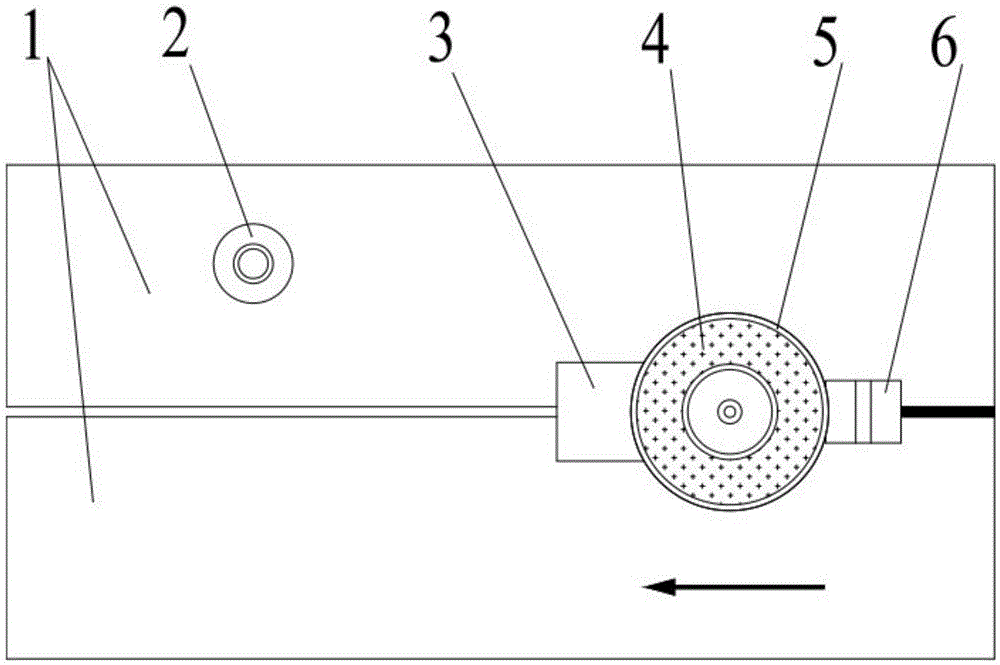

[0034] Example 1: Both the base material and the solder are selected from aluminum alloy

[0035] Step 1: Use ultrasonic to clean the surface of the aluminum alloy base metal to be welded. The ultrasonic power of the ultrasonic wave is 20w, and the cleaning time is 10min. Then put the two aluminum alloy sheets to be welded together;

[0036] Step 2: Melting the aluminum alloy solder in a metal melting furnace at a melting temperature of 700°C;

[0037] Step 3: applying semi-solid stirring during the cooling process of the aluminum alloy solder to make it have a two-phase structure of spherical grains and liquid phase;

[0038] Step 4: When the aluminum alloy solder is cooled to 620°C, pour it into a constant temperature injector, and keep it warm at 620°C, so that the liquid phase ratio of the solder is 50%;

[0039] Step 5: Turn on the in-situ induction heater, heat the aluminum alloy base material at the initial position of the area to be welded to 450°C, and keep it for 5s...

Embodiment 2

[0042] Example 2: Magnesium alloy is selected for base metal and solder

[0043]Step 1: Clean the surface of the magnesium alloy base material to be welded with ultrasonic waves, the ultrasonic power of the ultrasonic waves is 15w, and the cleaning time is 15min, and then put together the two magnesium alloy sheets to be welded;

[0044] Step 2: Melting the magnesium alloy solder in a metal melting furnace at a melting temperature of 710°C;

[0045] Step 3: applying semi-solid stirring during the cooling process of the magnesium alloy solder to make it have a two-phase structure of spherical grains and liquid phase;

[0046] Step 4: When the magnesium alloy solder is cooled to 600°C, pour it into a constant temperature injector, and keep it warm at 600°C, so that the liquid phase ratio of the solder is 60%;

[0047] Step 5: Turn on the in-situ induction heater, heat the magnesium alloy base material at the initial position of the area to be welded to 450°C, and keep it for 5s...

Embodiment 3

[0050] Example 3: SiCp / Al composite material is selected for base metal and solder

[0051] Step 1: Clean the surface of the SiCp / Al base metal to be welded with ultrasonic waves, the ultrasonic power of the ultrasonic waves is 20w, and the cleaning time is 10min, and then put together the two SiCp / Al sheets to be welded;

[0052] Step 2: Melting the SiCp / Al solder in a metal melting furnace at a melting temperature of 720°C;

[0053] Step 3: Apply semi-solid stirring during the cooling process of SiCp / Al solder to make it have a two-phase structure of spherical grains and liquid phase;

[0054] Step 4: When the SiCp / Al solder is cooled to 630°C, pour it into a constant temperature injector and keep it warm at 630°C so that the liquid phase rate of the solder is 60%;

[0055] Step 5: Turn on the in-situ induction heater, heat the SiCp / Al base material at the initial position of the area to be welded to 450°C, and keep it for 5s, then contact the ultrasonic vibration head with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com