Stainless steel honeycomb type heat exchanger and vacuum brazing method thereof

A brazing method and honeycomb technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of low structural strength of components, high material consumption, low production efficiency, etc. Uniform and stable heat input, simple overall structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]The present invention will be further described in detail below in conjunction with specific embodiments, but is not limited to the present invention.

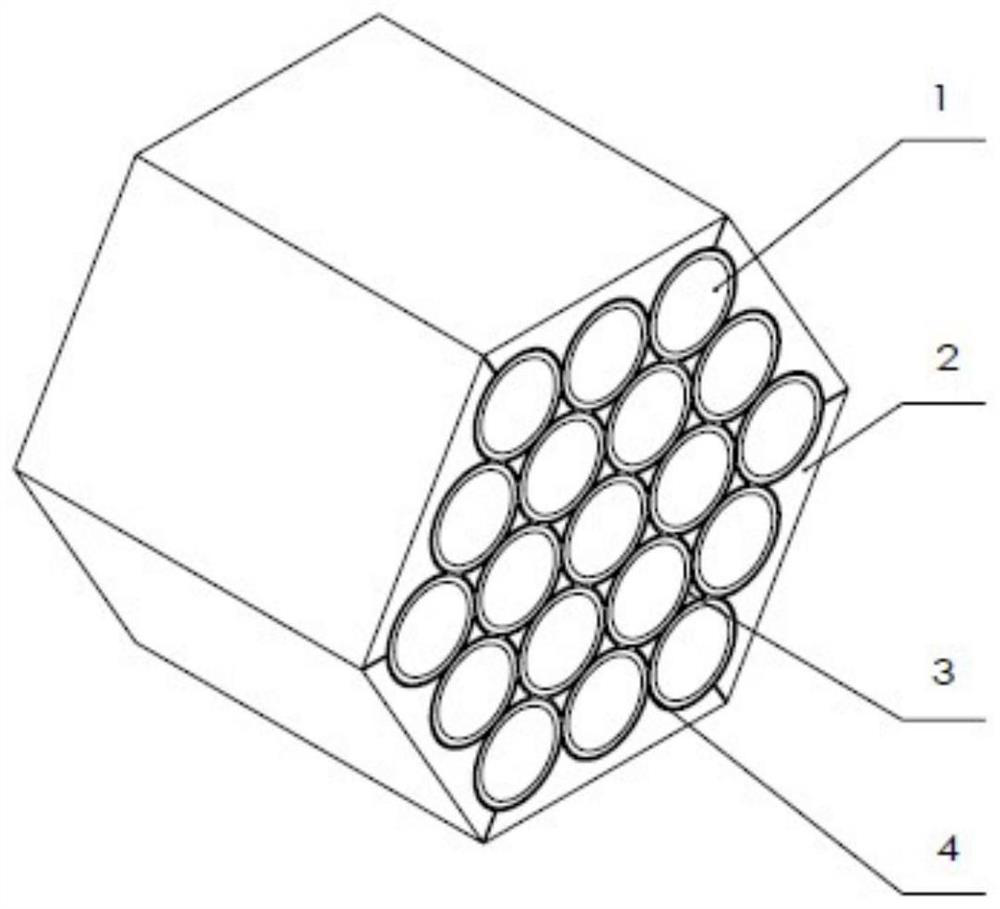

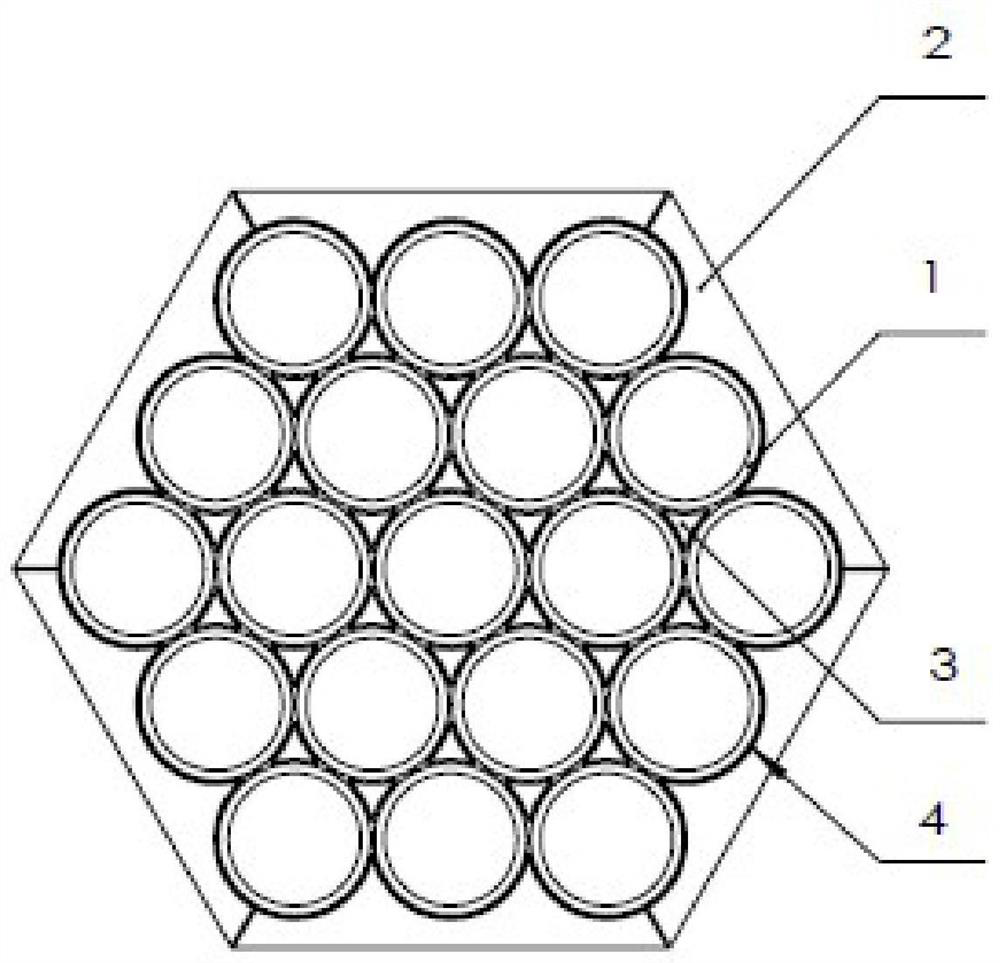

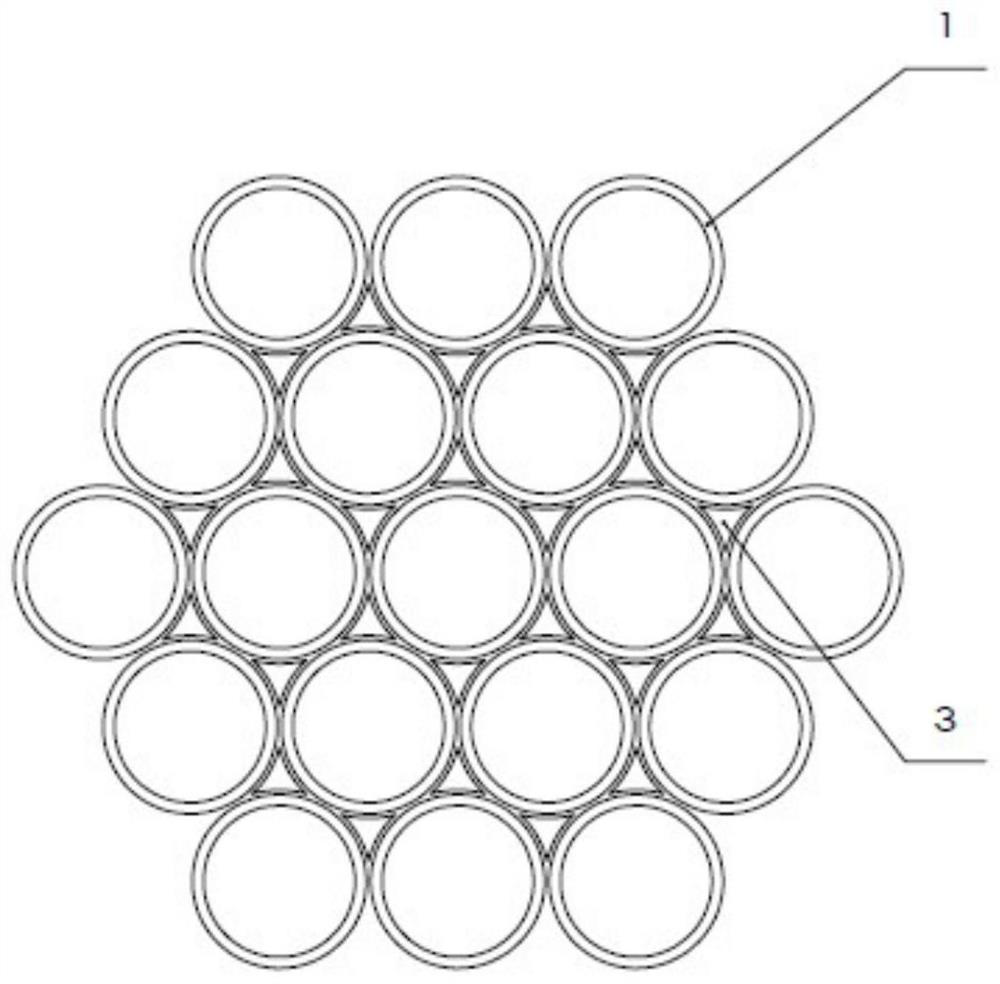

[0037]The stainless steel honeycomb heat exchanger of the present invention includes a circular tube 1, a trim prism 2, and an outer reticle 4; the circular tube 1 and the three prism 2 are arranged in an outer frame that is fixed in the outer block 4, and then brazed via vacuum brazing Welding solids form a cellular heat exchanger.

[0038]Vacuum brazing method of stainless steel honeycomb heat exchanger, including the following procedure:

[0039]Step 1, prepare before welding

[0040]The surface of the welder is polished in sequentially, washing with acetone, washing 10 min, removing impurities such as oil, rust, etc. of the surface of the component; then use the wi-water to carry out 30S acid washing until it exposes the metal gloss; finally alcohol ultrasound 10min, blow dry , Clean package. Using autonomous design semi-automatic TIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com