Metal production welding equipment

A welding equipment and metal technology, which is applied in the field of metal production and welding equipment, can solve the problems of waste of human resources, errors, damage to metal materials, etc., and achieve the effect of high welding efficiency and accurate welding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not used to limit the present invention.

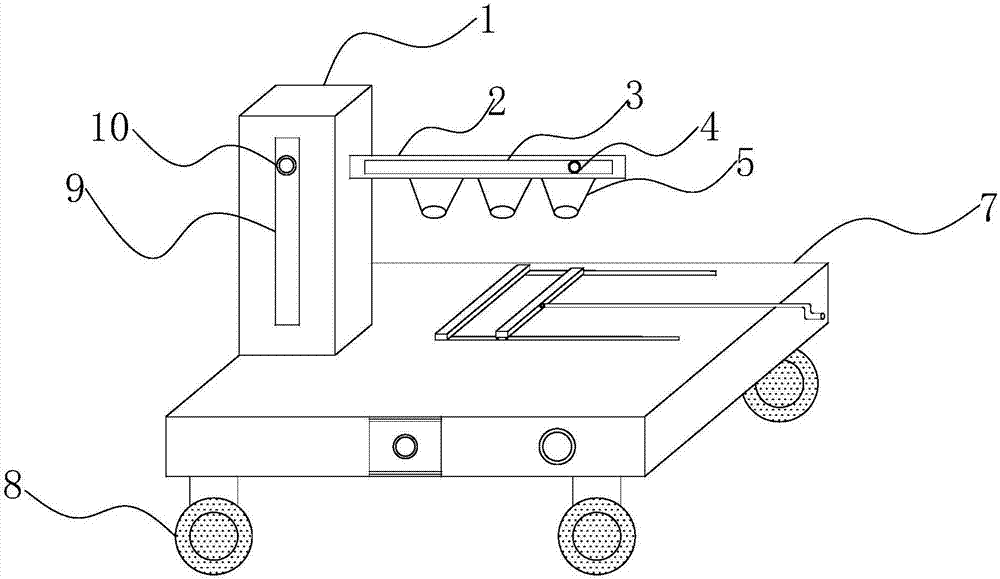

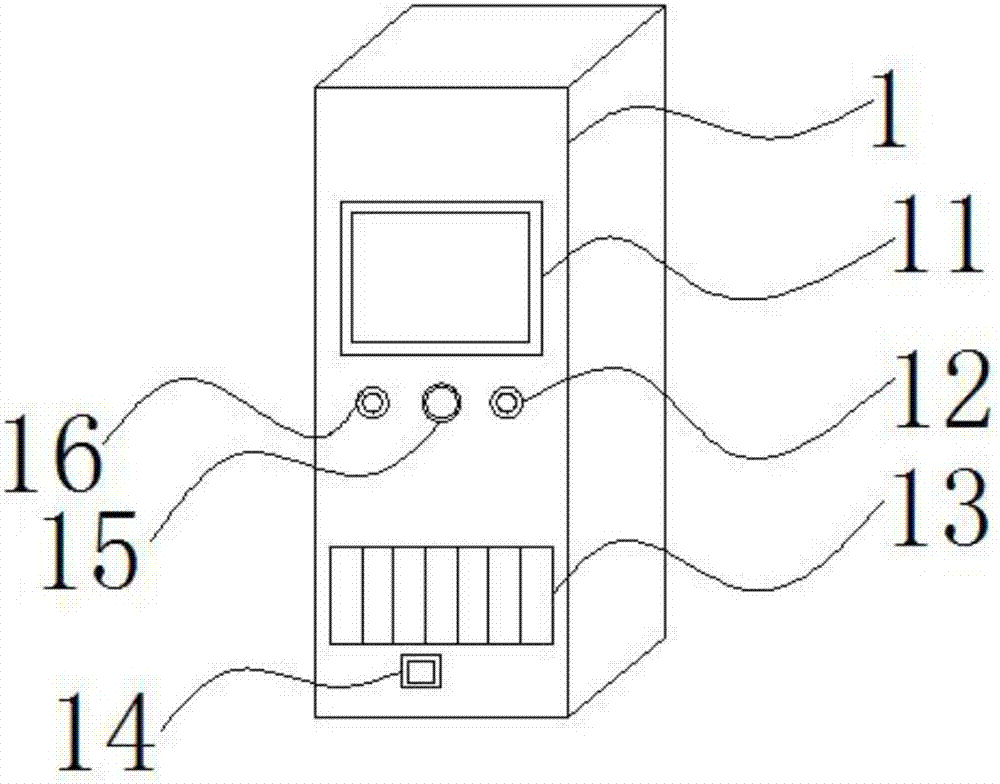

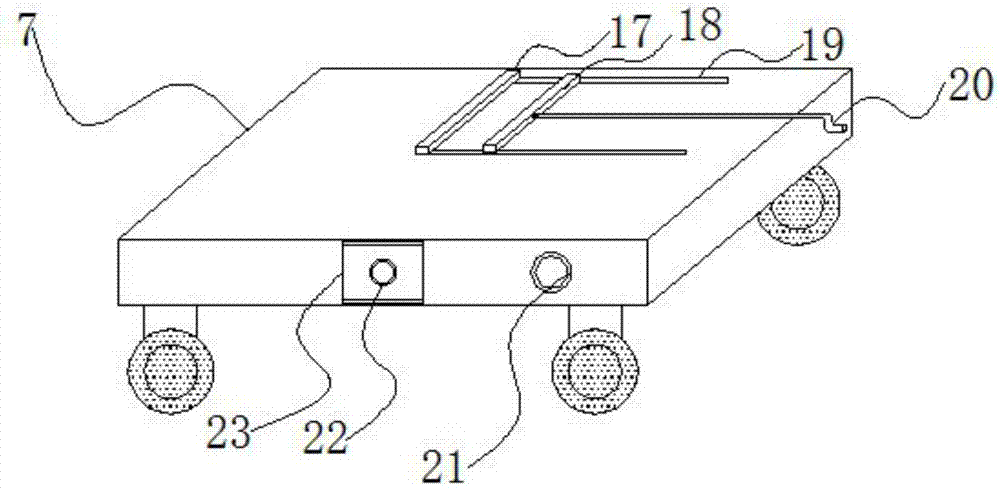

[0028] See Figure 1-7 , The present invention provides a technical solution: a metal production welding equipment, including a vertical connecting rod 1, a horizontal connecting rod 2, an adjustment cross rod 3, a first adjustment button 4, a welding device 5, a welding equipment base 7, a universal wheel 8. Adjust the vertical rod 9, the second adjustment button 10, the display screen 11, the mode switch button 12, the solar panel 13, the solar panel switch button 14, the power switch button 15, the temperature switch button 16, the fixing part 17, the sliding part 18. Sliding groove 19, hand crank 20, universal wheel switch button 21, storage cabinet knob 22, storage cabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com