Piping for refrigeration, production method and application

A manufacturing method and piping technology, applied in the field of composite pipes, can solve the problems of high welding cost and easy to be burned through, and achieve the effects of improving welding conditions, reducing welding cost and improving welding characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

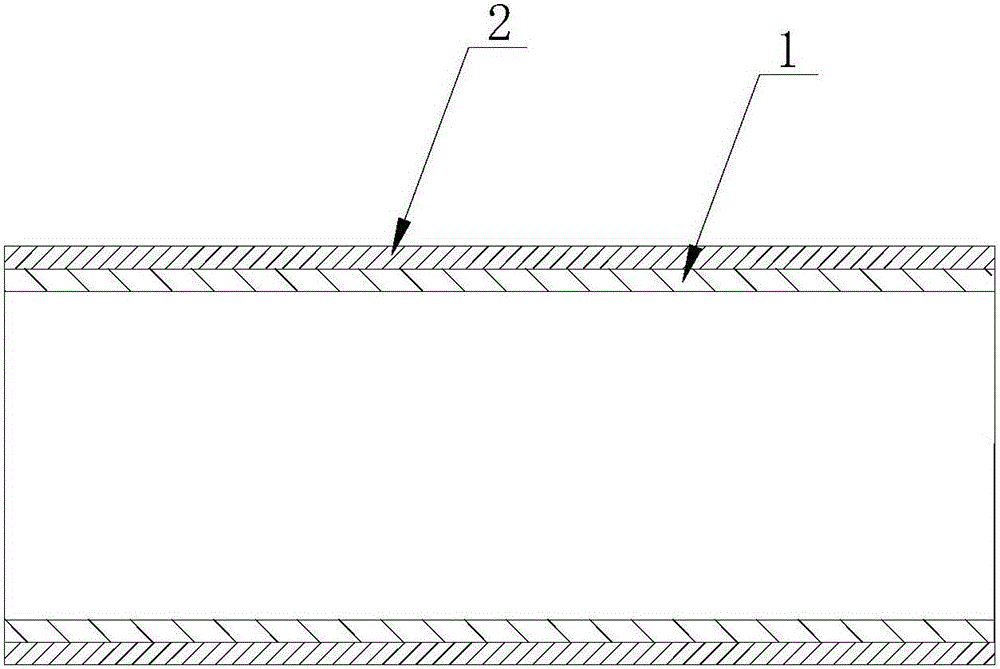

Image

Examples

Embodiment 2

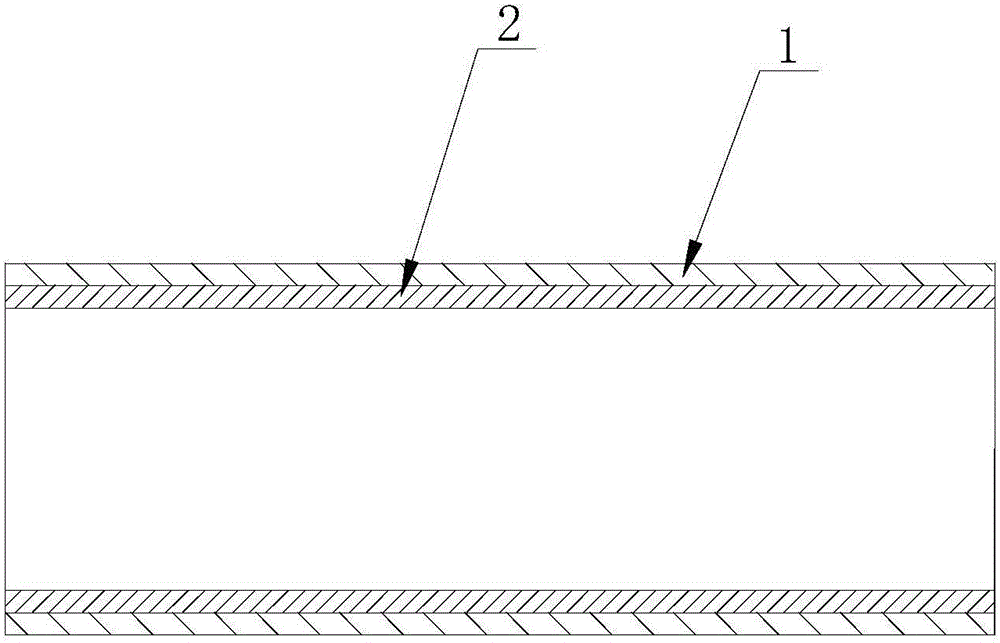

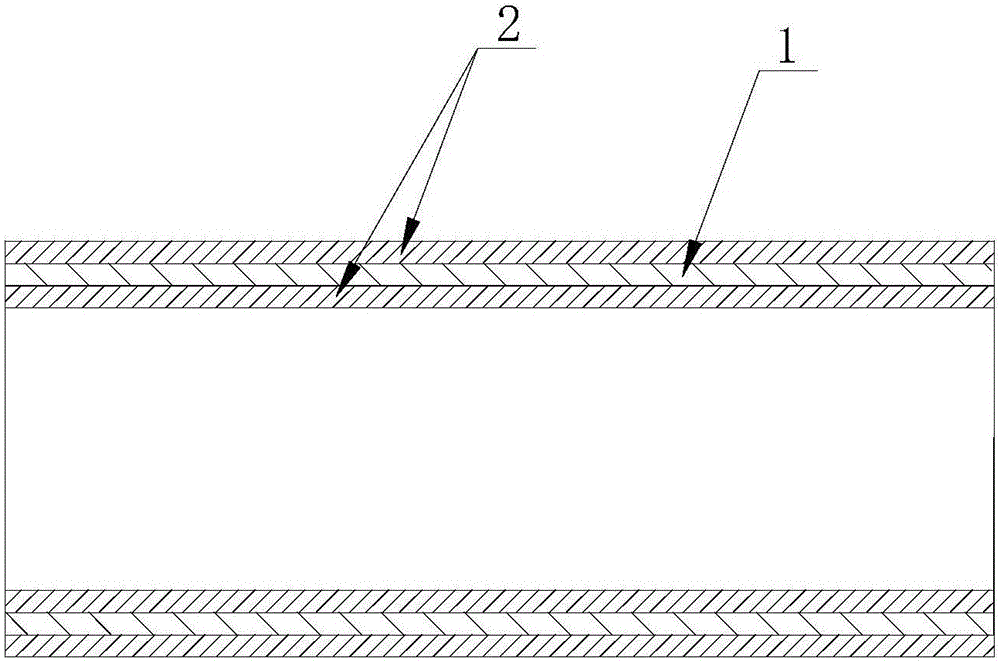

[0057] This embodiment is basically the same as Embodiment 1 and its variations, except that the method of manufacturing the cooling pipes is different. Such as Figure 9 As shown, the manufacturing method of the refrigeration pipe provided in this embodiment includes:

[0058] Step S1', obtain a tubular metal base layer 1. In this embodiment, the metal base 1 is a stainless steel tube. However, the present invention does not make any limitation thereto. In other embodiments, the metal base 1 can be a carbon steel pipe.

[0059] Step S2', forming at least one layer of copper covering layer 2 for connecting with external parts on the sidewall of the metal base layer 1. In this embodiment, a copper covering layer is formed on the outer wall of the metal base layer 1 by combining welding method and metallurgical rolling method. The forming steps are basically the same as the first embodiment, firstly, a layer of copper covering layer 2 is coated on the outer wall of the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com