Bimetal composite tube

A bimetal composite pipe and outer pipe technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problem of the decline of corrosion resistance of joints, the reduction of corrosion resistance and service life of pipelines, the dislocation of inner layer anti-corrosion alloys, etc. problems, to achieve the effect of convenient on-site welding, convenient quality inspection, and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

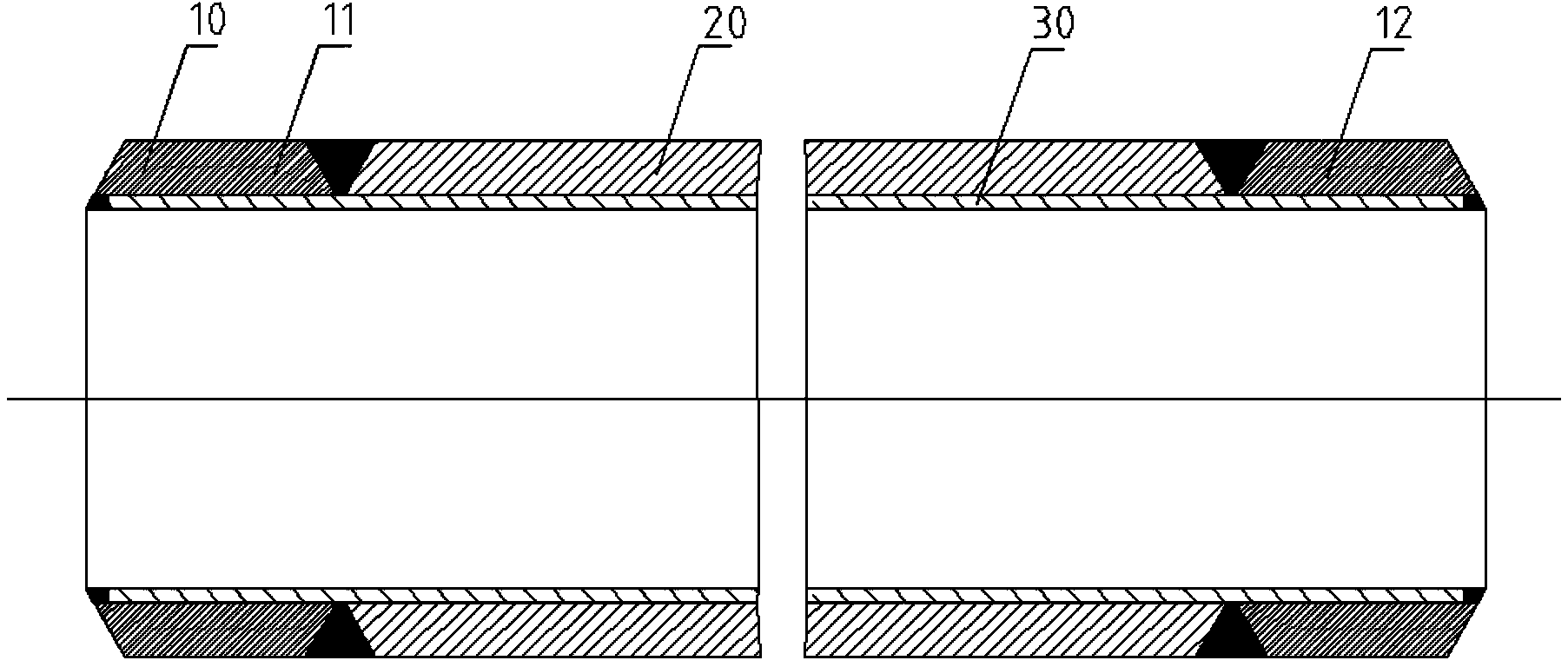

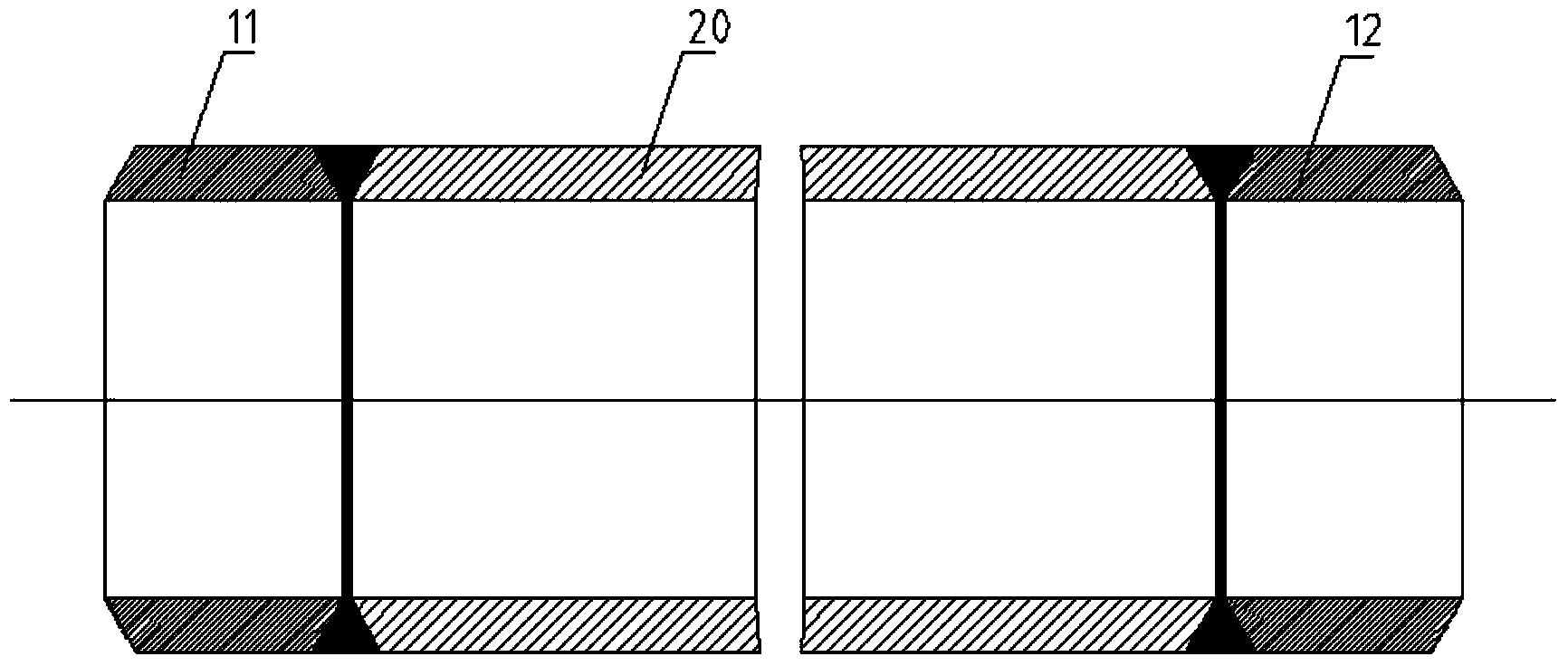

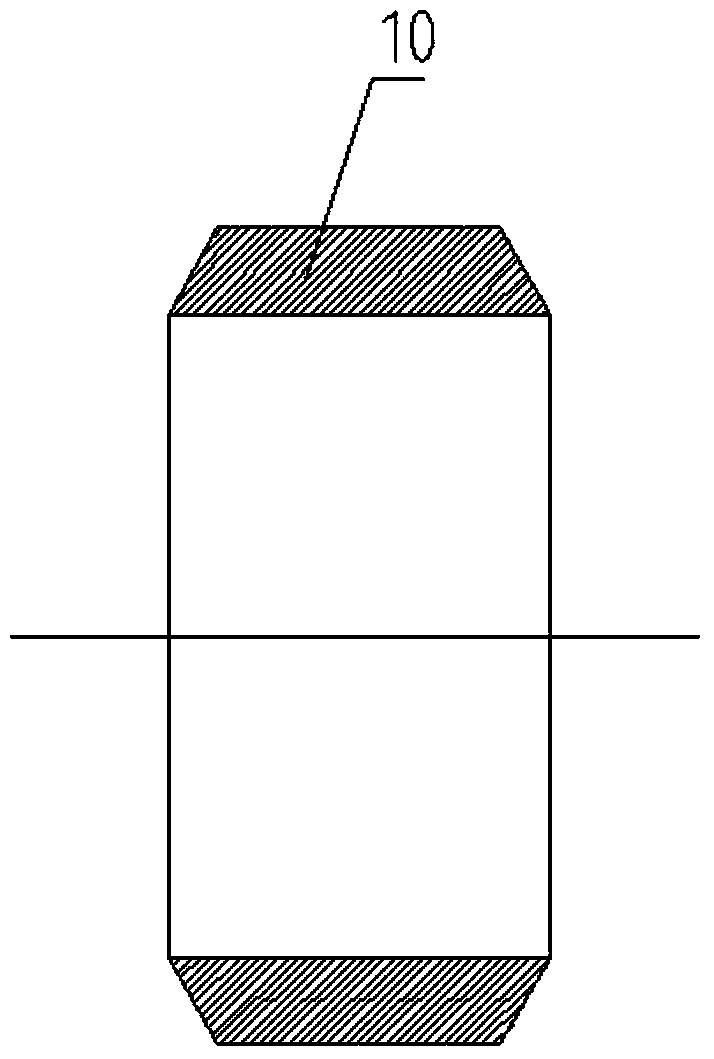

[0019] Such as figure 1 with figure 2 The shown bimetal composite pipe according to the present invention includes an outer pipe 20 and an inner pipe 30 , the inner pipe 30 is made of corrosion-resistant material, and the inner pipe 30 is located inside the outer pipe 20 . The bimetal composite pipe also includes a connecting portion 10 , the connecting portion 10 is connected to the outer pipe 20 by welding, and the inner pipe 30 is welded to the connecting portion 10 . The connection between the connecting part 10 of the bimetal composite pipe and the outer pipe 20 adopts a welding connection form. The inner pipe 30 made of corrosion-resistant material can ensure that the corrosive medium in the inner pipe 30 does not contact the outer pipe 20 when there is a corrosive medium in the oil and gas well, ensuring the safety of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com