Chain welding machine used for butt welding of chain link resistors

A technology of resistance butt welding and welding machines, which is applied in the direction of resistance welding equipment, welding equipment, metal chains, etc., can solve the problems of complex modification and achieve the effect of short total process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

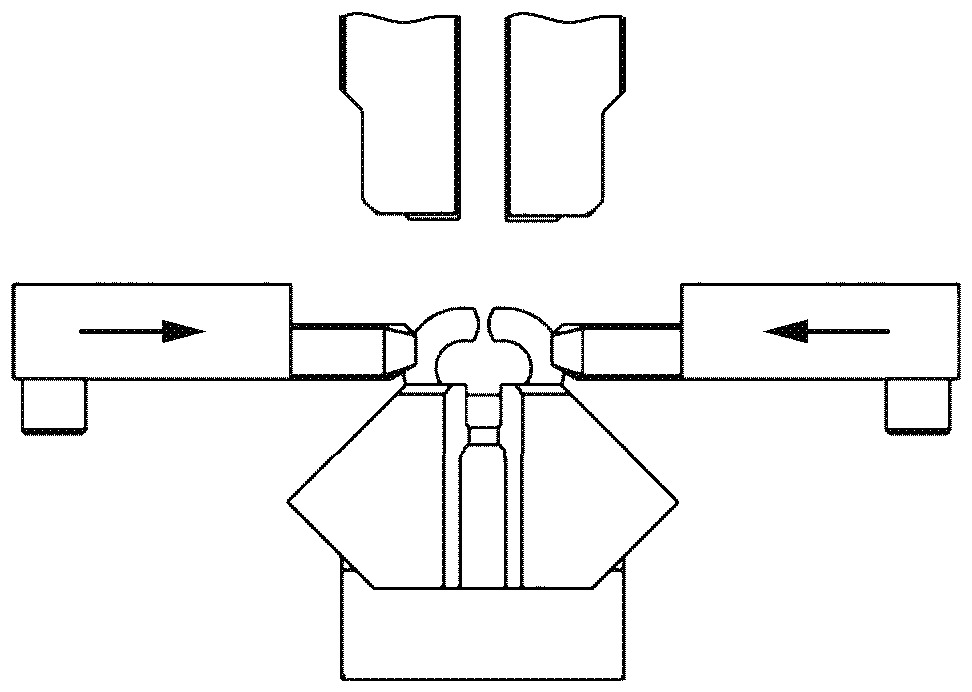

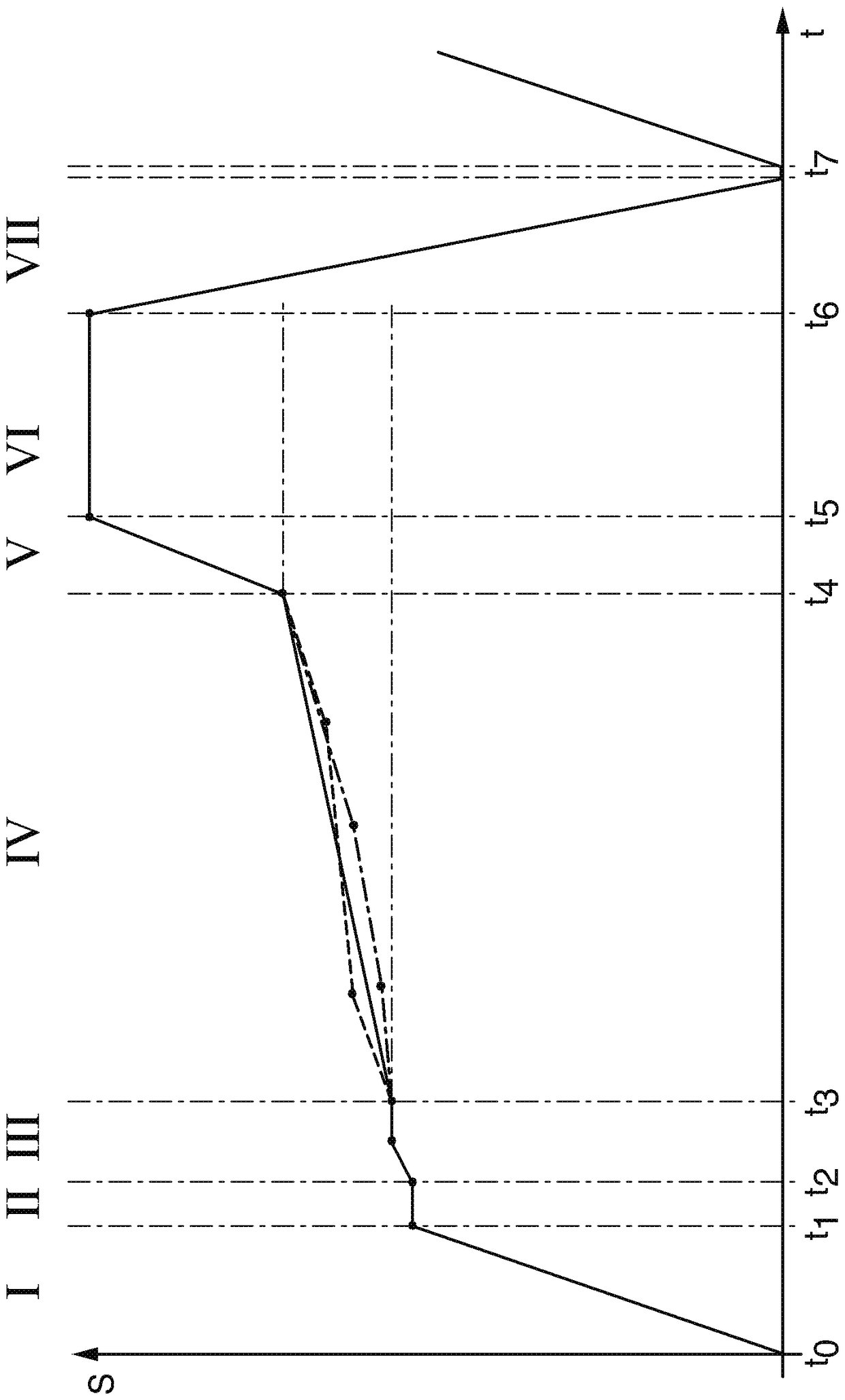

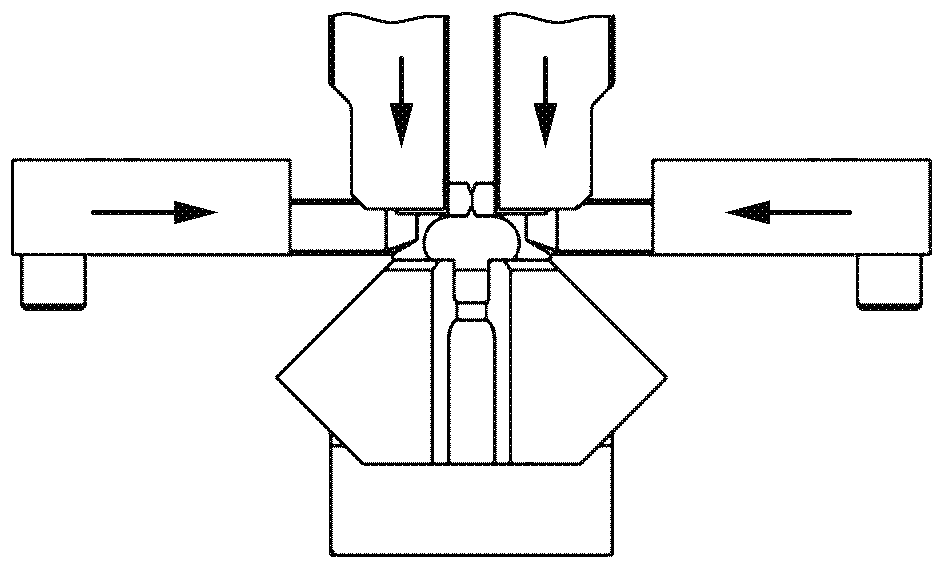

[0043] exist figure 1 An oblique perspective view of a chain welding machine 100 according to an embodiment for extruding butt welding chain links is schematically shown in . The chain welding machine has a frame 110 , which consists in part of welded steel sheets and has an extremely bending-rigid and load-bearing configuration. Inside the machine frame, a control shaft accessible from the rear side is supported with a horizontal axis of rotation. The mechanical control shaft is driven by means of an asynchronous servomotor, which enables a force transmission relative to the control shaft via a belt drive or chain drive or a gear mechanism. Starting from the control shaft, a large number of kinematic functions are controlled over time via the cam disc and the eccentric, but the forging process is not controlled. Path reduction and force increase are achieved by means of appropriately designed levers and deflections. The forces required for the respective functions are appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com