Diffusion connection method of cylinder wall structure

A diffusion connection and cylinder wall technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of increasing the difficulty of tooling and welding process uncertainty, and achieve the elimination of process instability, uniform stress, and improved uniformity effect on sex and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The invention discloses a diffusion connection method of a cylindrical wall structure, and the inner and outer structural materials are all copper alloys. The difference between the inner diameter of the outer wall and the outer diameter of the inner wall of the wall-shaped structure is 0.02%. The inner wall is placed in liquid nitrogen for 20 minutes and then quickly loaded into the outer wall. After assembly, the workpiece is subjected to high-temperature diffusion welding. The welding temperature is higher than the design temperature. Lower the temperature by 4°C and reduce the holding time by 4 minutes.

Embodiment 2

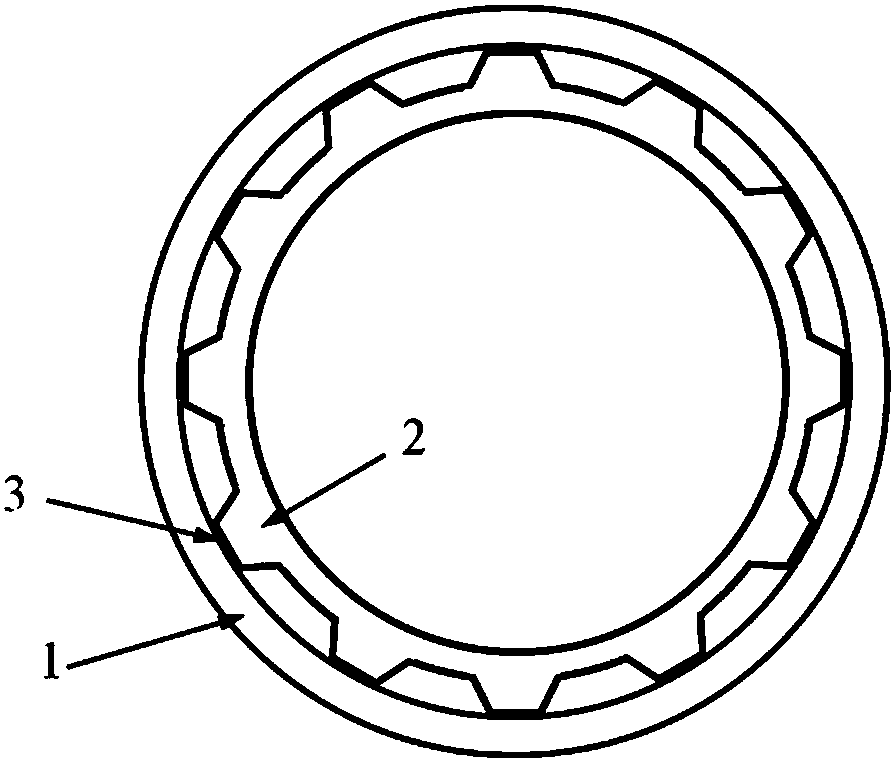

[0019] The invention discloses a diffusion connection method of a tapered cylinder wall structure, and the inner and outer structural materials are copper alloy and aluminum alloy. Fix the intermediate layer with a thickness of 0.1 mm on the corresponding position on the outer surface of the inner cylinder wall by spot welding, and the difference between the inner diameter of the outer cylinder wall and the outer diameter of the inner cylinder wall of the cylinder wall structure is 0.05%, such as figure 1 As shown, the inner cylinder wall is placed in liquid nitrogen for 24 minutes and then quickly loaded into the outer cylinder wall, and the buckles are fixed on the upper and lower sides to prevent the inner and outer cylinders from slipping. After assembly, the workpieces are subjected to high-temperature diffusion welding. The holding time is reduced by 9 minutes.

Embodiment 3

[0021] The invention discloses a diffusion connection method of a trapezoidal cylinder wall structure, and the inner and outer structural materials are stainless steel and aluminum alloy. The middle layer with a thickness of 0.15mm is fixed on the corresponding position on the outside of the inner cylinder wall by spot welding. The difference between the inner diameter of the outer cylinder wall and the outer diameter of the inner cylinder wall of the cylinder wall structure is 0.10%, and the inner cylinder wall is in liquid nitrogen. After placing it for 26 minutes, quickly put it into the wall of the outer cylinder, and fix the buckles on the upper and lower sides to prevent the inner and outer cylinders from slipping. After assembly, the workpieces are subjected to high-temperature diffusion welding. The welding temperature is 30°C lower than the design temperature, and the holding time is reduced by 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com