Diffusion welding method of dissimilar metal

A dissimilar metal, diffusion welding technology, used in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problem of aluminum-steel brazing joints not resistant to air corrosion, differences in physical and chemical properties, and low joint reliability. problems, to achieve the effect of ensuring welding quality and welding rate, ensuring welding quality, and reducing deformation of weldments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

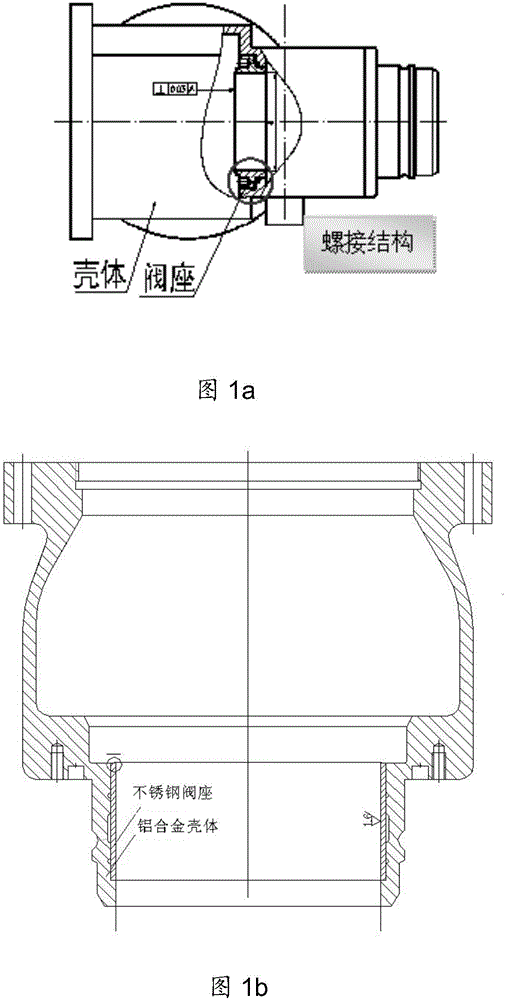

[0051] The following is an example of diffusion welding of dissimilar metals, aluminum alloy and stainless steel. Aluminum and steel are typical dissimilar metal welded joints, and are also one of the most difficult material combinations among dissimilar metals. In this embodiment, 0Cr18Ni9 stainless steel and LD10 aluminum alloy tubes are used.

[0052] (1) Welding joint design:

[0053] (1) The joint form of aluminum-clad steel: Since the thermal expansion coefficient of aluminum is much greater than that of stainless steel, the shrinkage of aluminum is greater than that of stainless steel when the joint is at room temperature or lower temperature, making the aluminum-steel joint stronger;

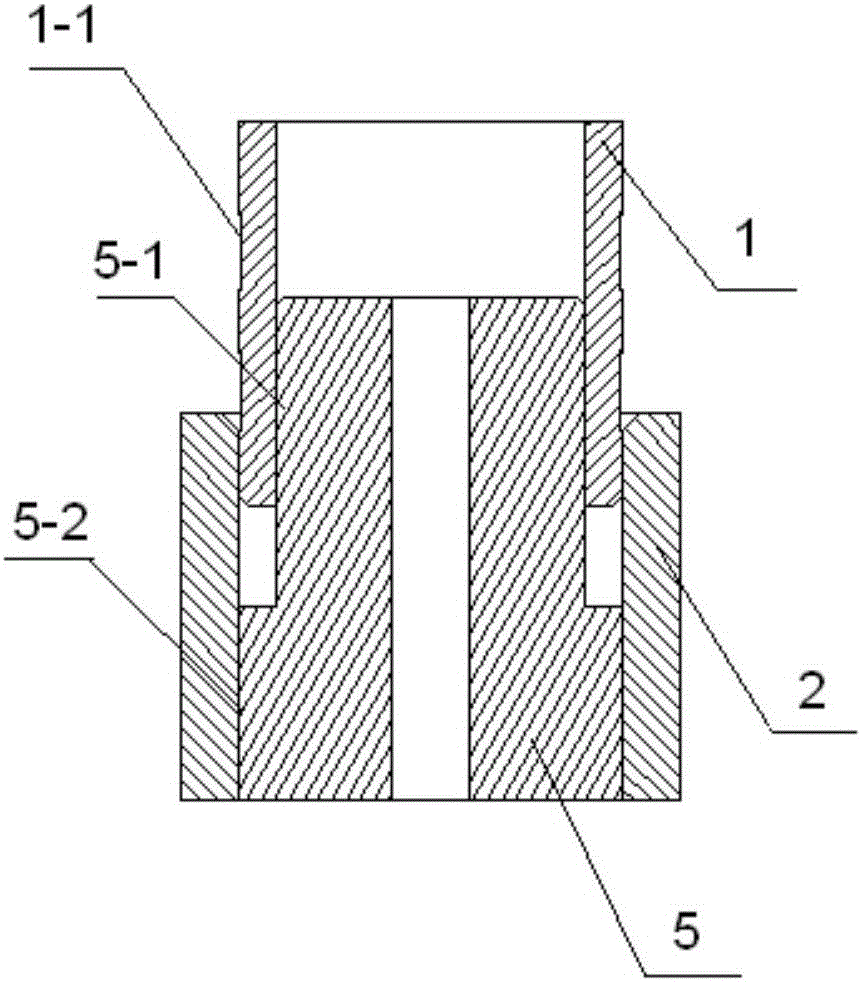

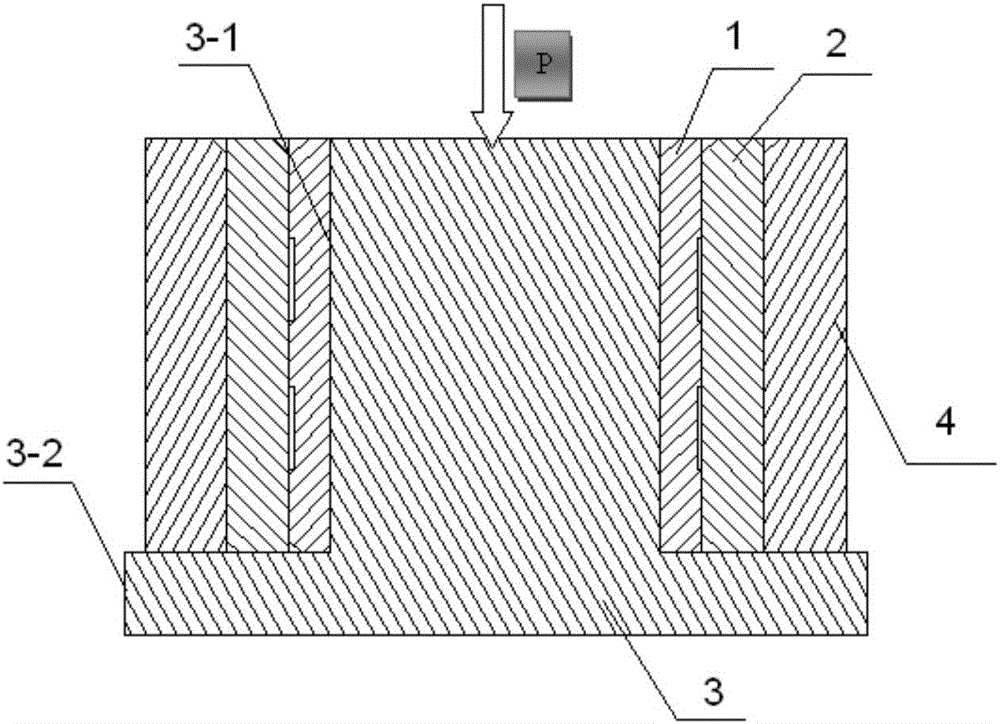

[0054] (2) The method of interference fit of the cylindrical surface: before welding, the inner wall of the aluminum alloy tube and the outer wall of the stainless steel tube are processed into an interference fit cylindrical surface. The design idea: ① Remove the oxide film on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com