Laser welded tube fitting structure and gas generator with the tube fitting structure

A gas generator, laser welding technology, applied in laser welding equipment, manufacturing tools, welding equipment and other directions, can solve problems such as steel type restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

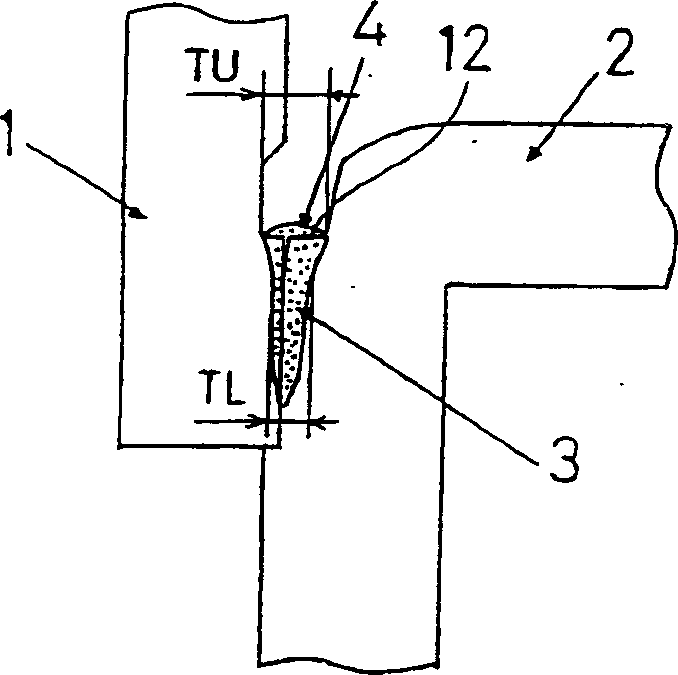

[0062] In FIG. 4 , a JISG3452 SPG steel material of φ60.5 mm and a plate thickness of 3.5 mm is machined into a cylindrical shape to produce a first steel member 1 . Furthermore, JISG3141 SPCD steel material of plate thickness 3mm was press-molded, after that, this was machined, and the cylindrical 2nd steel member 2 which has a flange part was produced.

[0063] This first steel member 1 is inserted into the second steel member 2 to form a flared joint 7 whose bevel shape is a flared レ shape.

[0064] Then, as shown in FIG. 5( b ), an I-groove-shaped flat portion 4 is formed on the second steel member. The width of the flat portion 4 is TS [mm].

[0065] Moreover, as shown in FIG. 5(c), an I-groove-shaped flat portion 4 is formed on the first steel member and the second steel member. The width of the aforementioned flat portion 4 is TD [mm].

[0066] CO2 laser welding was carried out within the range of welding conditions shown in Table 1 in FIG. 14 . Then, it was checked...

Embodiment 2

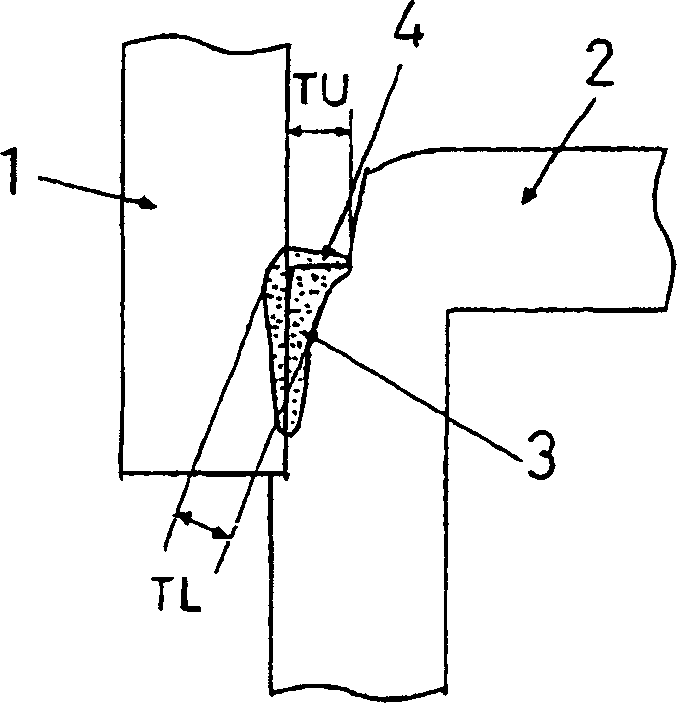

[0078] In FIG. 7 , a disc-shaped first steel member 1 is molded by press-forming a JISG3141 SPCD steel material having a plate thickness of 3 mm, and then performing machining. These are combined and embedded in the second steel member 2 having a flange portion to form a flared joint 7 whose bevel shape is a flared V shape.

[0079] Then, as shown in FIG. 8( c ), an I-groove-shaped flat portion 4 is formed on the first steel member and the second steel member. The width of the aforementioned flat portion 4 is TD [mm].

[0080] YAG laser welding is performed on it, and the presence or absence of cracks is investigated through the surface and cross-sectional investigation of the welded part.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com